A packaged emulsified ammonium oil explosive and its preparation method

A technology of ammonium oil explosives and emulsifiers, applied in explosives processing equipment, explosives, offensive equipment, etc., can solve problems such as inability to apply off-site mixing occasions, affect product safety storage, and reduce product detonation sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

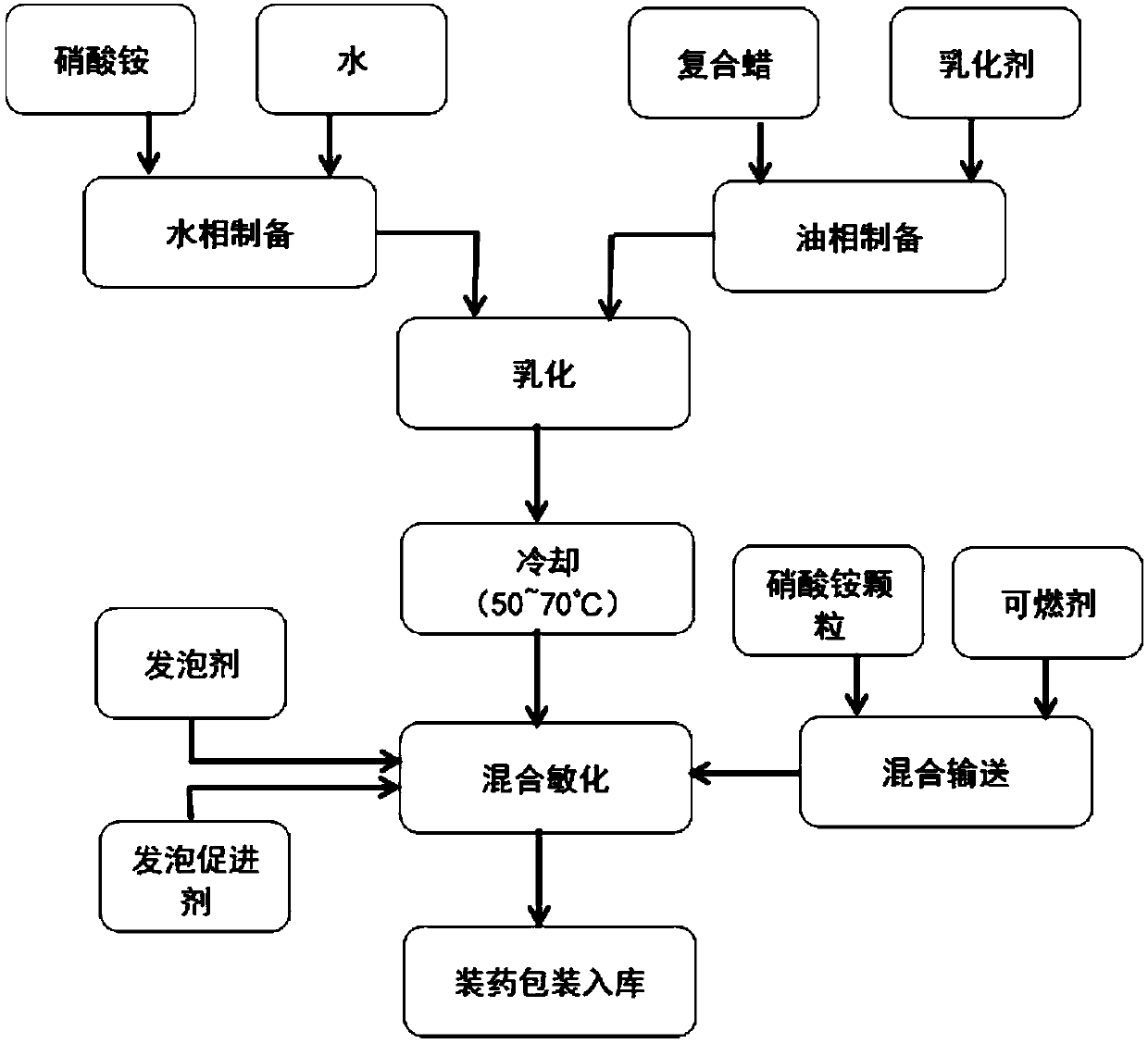

[0020] Example 1: This example is carried out on the production line of the emulsion explosive experiment. Ammonium nitrate, sodium nitrate, and water are made into an aqueous phase solution according to the ratio of the formula, and the temperature is raised to 97°C for later use. The composite wax and emulsifier are prepared according to the formula. The ratio is made into an oil-phase molten liquid, and the temperature is raised to 95°C for later use. The water and oil phase liquids are transported to the static emulsifier according to a certain ratio through their respective pumps for emulsification. After the emulsified latex matrix is cooled to 70°C on the steel belt cooler, it is sent to the powder filling machine by the belt conveyor. in the hopper. Latex matrix formula is as follows Table 1:

[0021] Table 1: Latex Matrix Formulations

[0022] components

Formula ratio (%)

ammonium nitrate

75

sodium nitrate

10

water

9.5

...

Embodiment 2

[0033] Embodiment 2: The formula of latex matrix used in this embodiment is shown in Table 5, and the production process is the same as in Example 1. The temperature of the latex matrix is controlled at 50° C., and the formula of emulsified ammonium oil explosives has been changed. The formula is shown in Table 6. Mix After the temperature is 40°C:

[0034] Table 5: Embodiment 2 latex matrix formula

[0035] components

Formula ratio (%)

ammonium nitrate

85

water

8.5

Emulsifier (SP-80)

2.5

Composite wax

4

[0036] Table 6: Formula of embodiment 2 emulsified ammonium oil explosives

[0037] components

Formula ratio (%)

Latex base

79.5

19

Combustible agent (diesel)

1

Foaming agent (sodium nitrite solution)

0.2

Foam accelerator (citric acid solution)

0.3

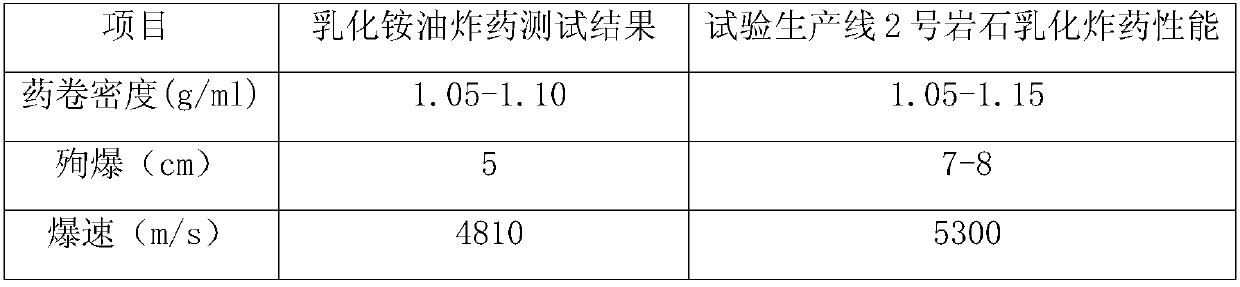

[0038] Embodiment 2 emulsified ammonium oil explosive performance and st...

Embodiment 3

[0041] Embodiment 3: This embodiment is carried out on the production line of the emulsion explosive experiment. Ammonium nitrate, sodium nitrate, and water are made into an aqueous phase solution according to the ratio of the formula, and the temperature is raised to 97°C for later use. The composite wax and emulsifier are prepared according to the formula. The ratio is made into an oil-phase molten liquid, and the temperature is raised to 95°C for later use. The water and oil phase liquids are transported to the static emulsifier according to a certain ratio through their respective pumps for emulsification. After the emulsified latex matrix is cooled to 60°C on the steel belt cooler, it is sent to the powder filling machine by the belt conveyor. in the hopper. Latex matrix formula is as follows Table 8:

[0042] Table 8: Example 3 latex matrix formulation

[0043] components

[0044] At the same time, the foaming agent and the foaming accelerator are sent into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com