A strain-based method for steel corrosion monitoring

A steel bar corrosion and steel bar technology, which is applied in the field of steel bar corrosion monitoring, can solve the problems of being easily affected by environmental humidity, temperature, electromagnetic interference, inability to detect the degree of steel bar corrosion, low accuracy and reliability, etc., achieving low test cost, Precise positioning detection, ensuring safe and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A specific embodiment of the present invention is a steel corrosion monitoring method based on strain, comprising the steps of:

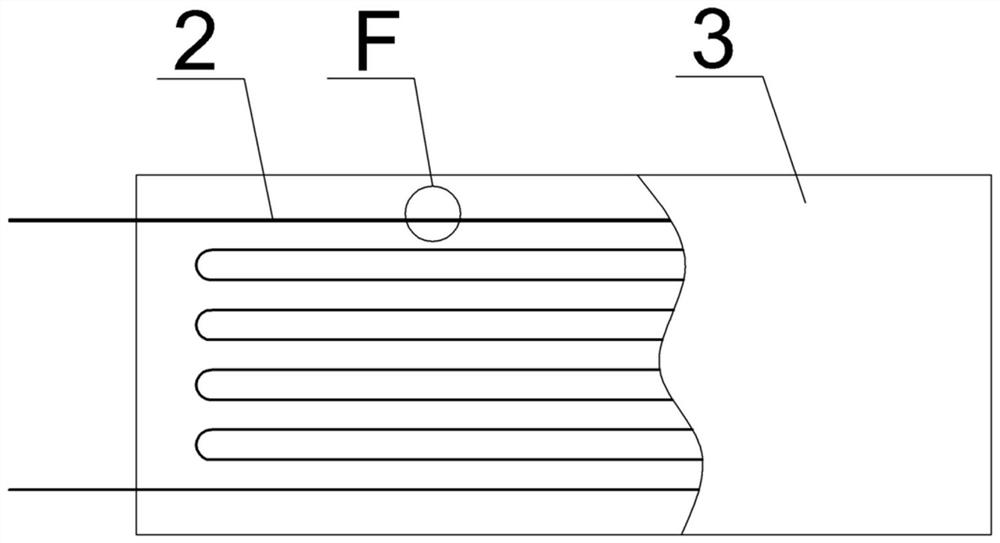

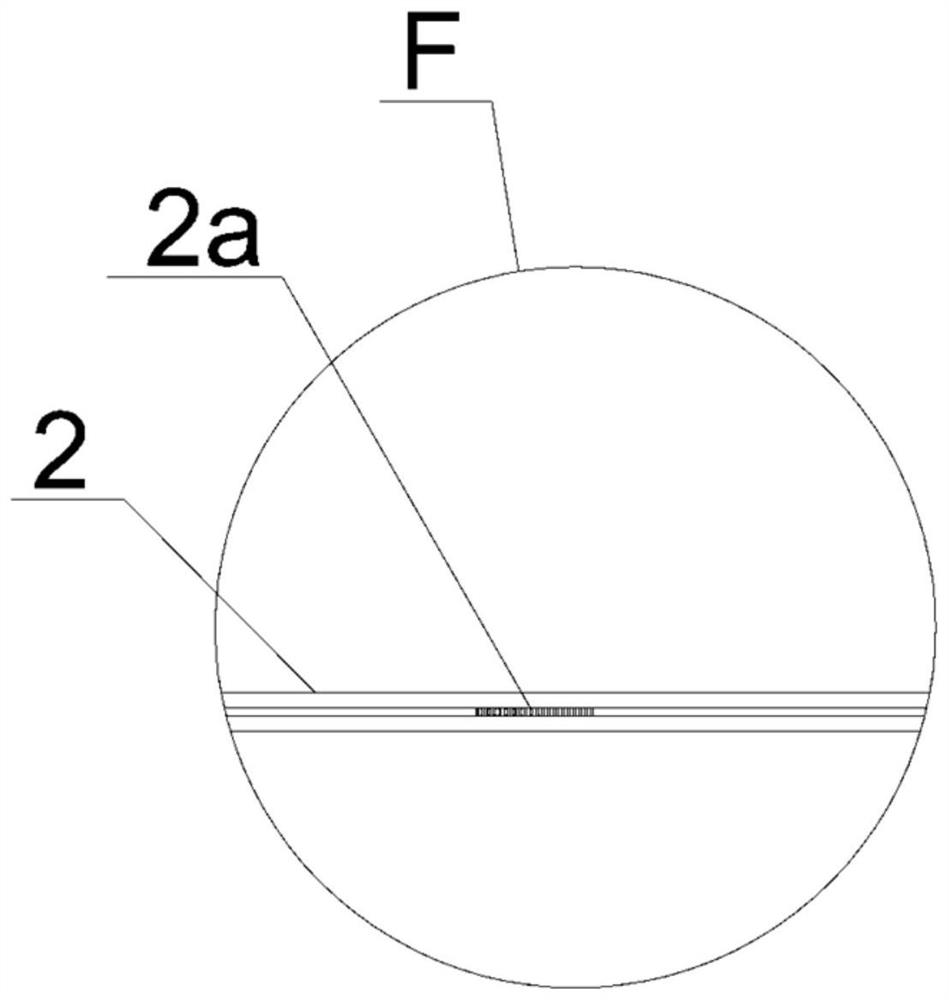

[0025] A, a length of 5-20 times the length of the steel test optical fiber strain sensors 2, uniformly winding a laminated wrapping layer 3 is composed of two layers of nylon cloth elongated in the optical fiber strain sensor 2 and the leading end of the end leads each optical fiber at the same side wrapping layer 3 is exposed; 2 of the optical fiber strain sensors to a plurality of equally spaced grating strain sensors 2a optical fiber strain sensors; see figure 1 , 2 ;

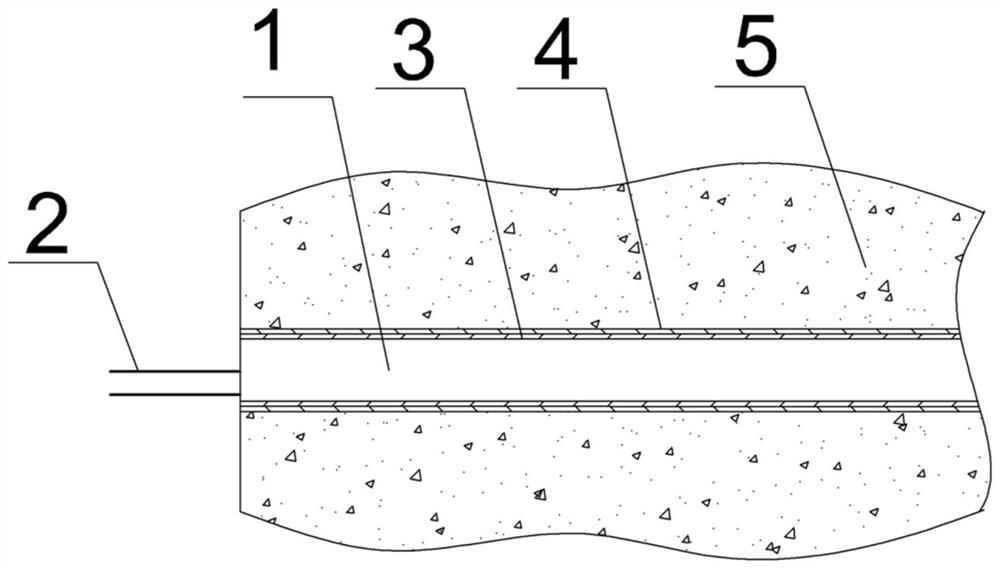

[0026] B, with a wound optical fiber strain sensor wrap layer 3 against the package 2 to be tested on a reinforced steel cage; then using foam layer of sponge 4 is wound on the package in close contact layer 3, is embedded optical fiber strain obtained 2, the sensor reinforcement cage;

[0027] C, the optical fiber strain sensors are embedded reinforcement cage pouring templat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com