Internet-of-things remote control method for biomass burner

A remote control and burner technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems affecting the quality of biomass combustion, low degree of automation, high labor intensity, etc., to achieve automatic intelligent management, automation High-level, easy-to-promote effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

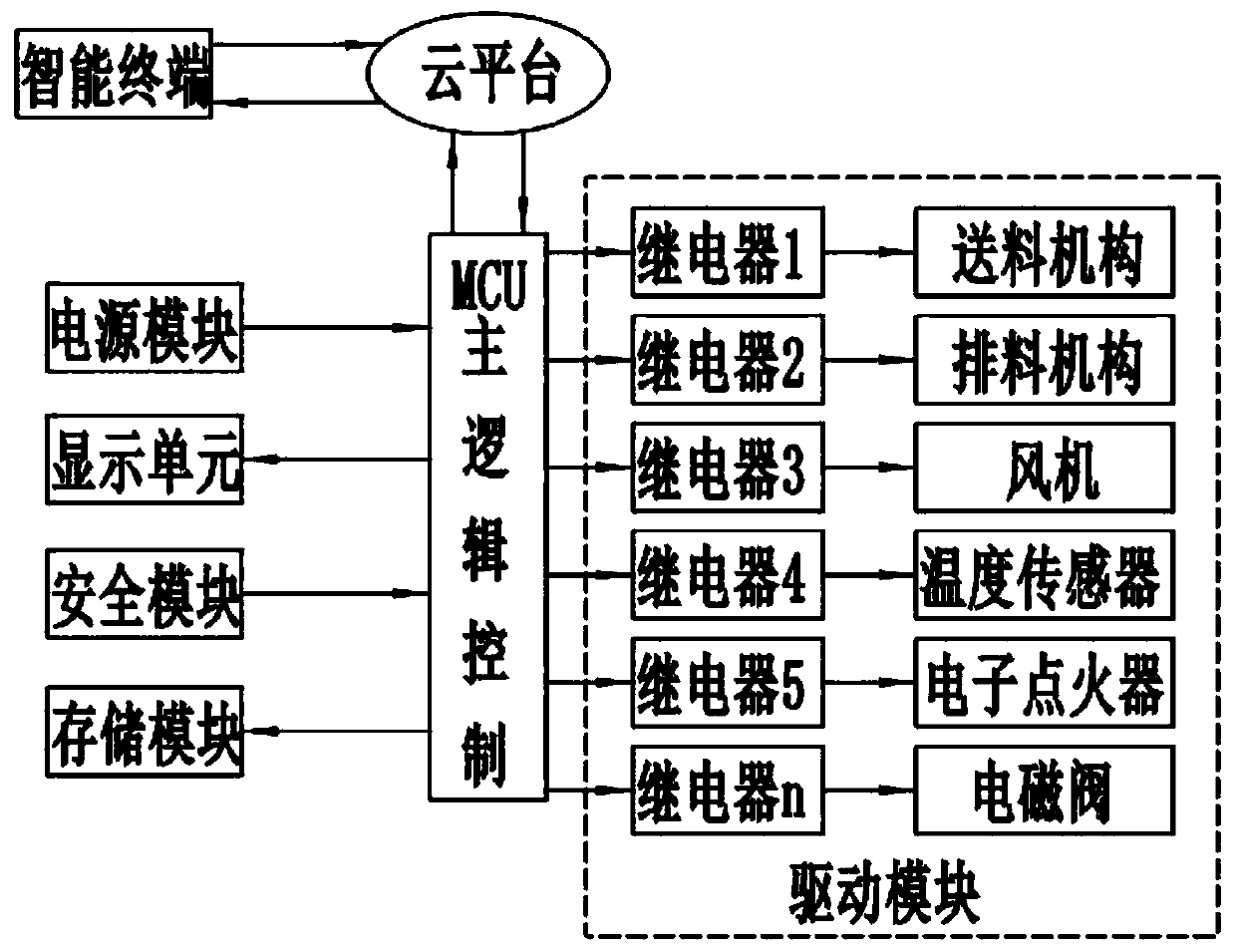

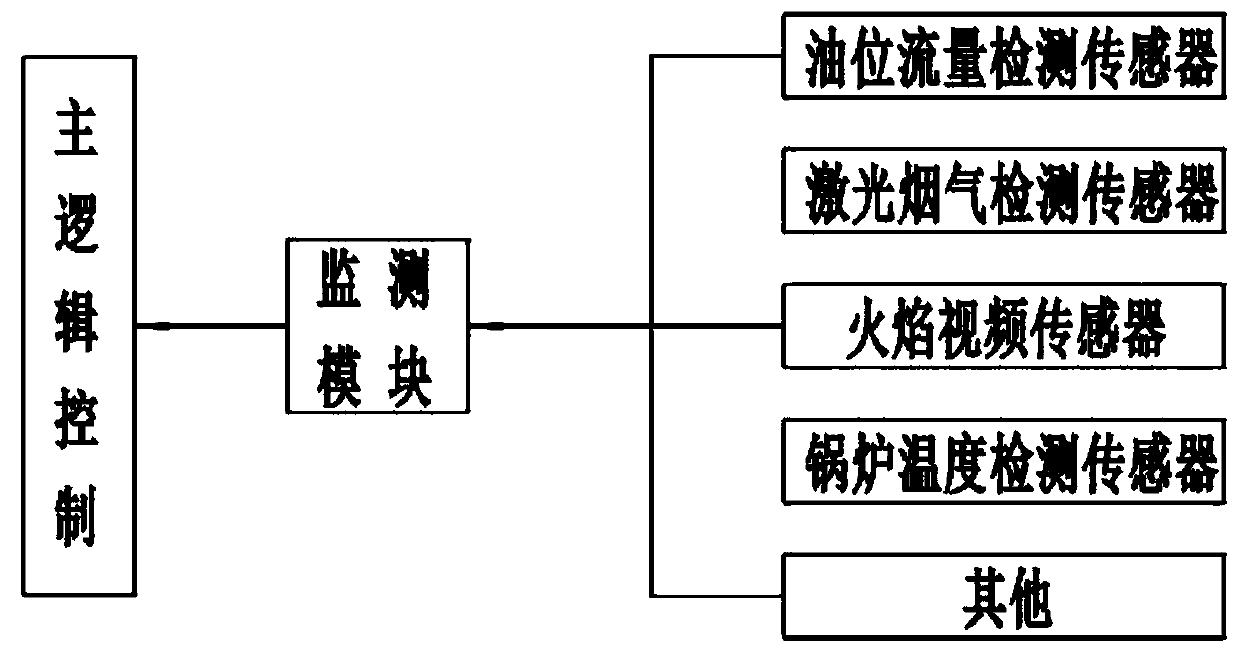

[0025] refer to Figure 1-4 , an IoT remote control method for a biomass burner, including a drive module, a user-controlled intelligent terminal and MCU main logic control, and a cloud platform for transmitting signals and control commands between the intelligent terminal and the MCU main logic control , power module, display unit, security module and storage module;

[0026] Drive module: used to drive the electronic components inside the biomass burner;

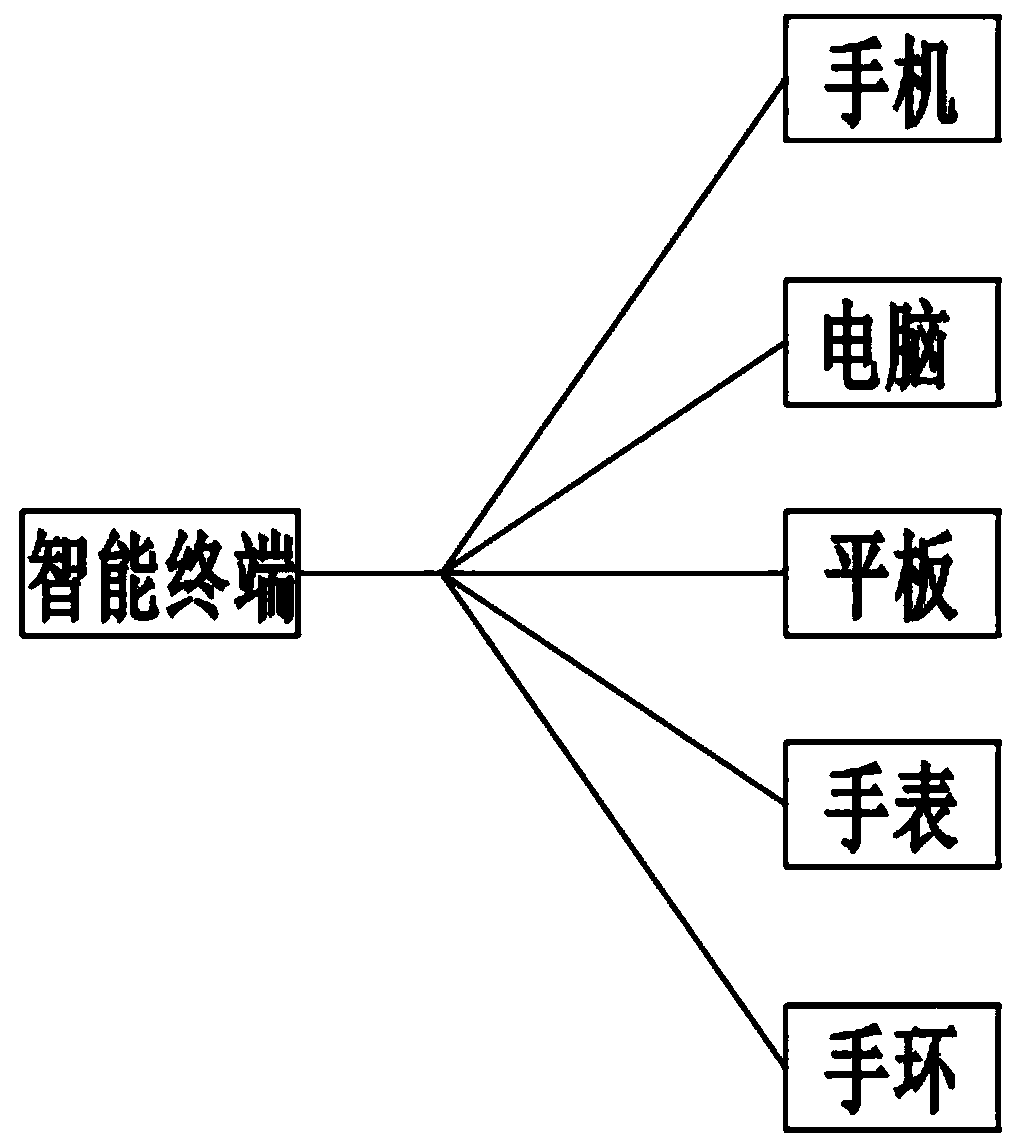

[0027] Intelligent terminal: used to produce user's control instructions;

[0028] Cloud platform: perform data interaction, realize data return and command sending;

[0029] MCU main logic control: MCU main logic control is set in the body of the biomass burner, receives instructions from the smart terminal through the cloud platform, and realizes the control of the drive module;

[0030] Power supply module: used for MCU main logic control to provide power supply, using a dedicated power supply to avoid the MCU main l...

Embodiment 2

[0048] refer to Figure 5 , a remote control method for the Internet of Things for a biomass burner, which includes the following steps:

[0049] Preparation: Use any of mobile phones, computers, tablets, watches, and bracelets to form a pairing connection with the MCU main logic control via the cloud platform;

[0050] (1) Start-up: The operator controls the action of the relay inside the biomass burner by starting the virtual button on the smart terminal, so that the blower and the slag discharge drive motor start for 60-300s, and the working power of the blower at this time is its rated power Power, the slag discharge drive motor will drive the slag discharge screw to rotate and discharge the slag in the furnace body, and the blower can cooperate with the slag discharge screw to clean the furnace ash in the furnace body;

[0051] (2) Pre-feeding: The operator controls the action of the relay inside the biomass burner by starting the virtual button on the smart terminal, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com