LPDDR substrate design method, LPDDR substrate and electronic equipment

A design method and substrate technology, applied in the direction of electrical components, printed circuits, printed circuit manufacturing, etc., can solve the problems of lead wire residue, etc., achieve the effect of centralized etching area, convenient inspection, and meet performance requirements and aesthetic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

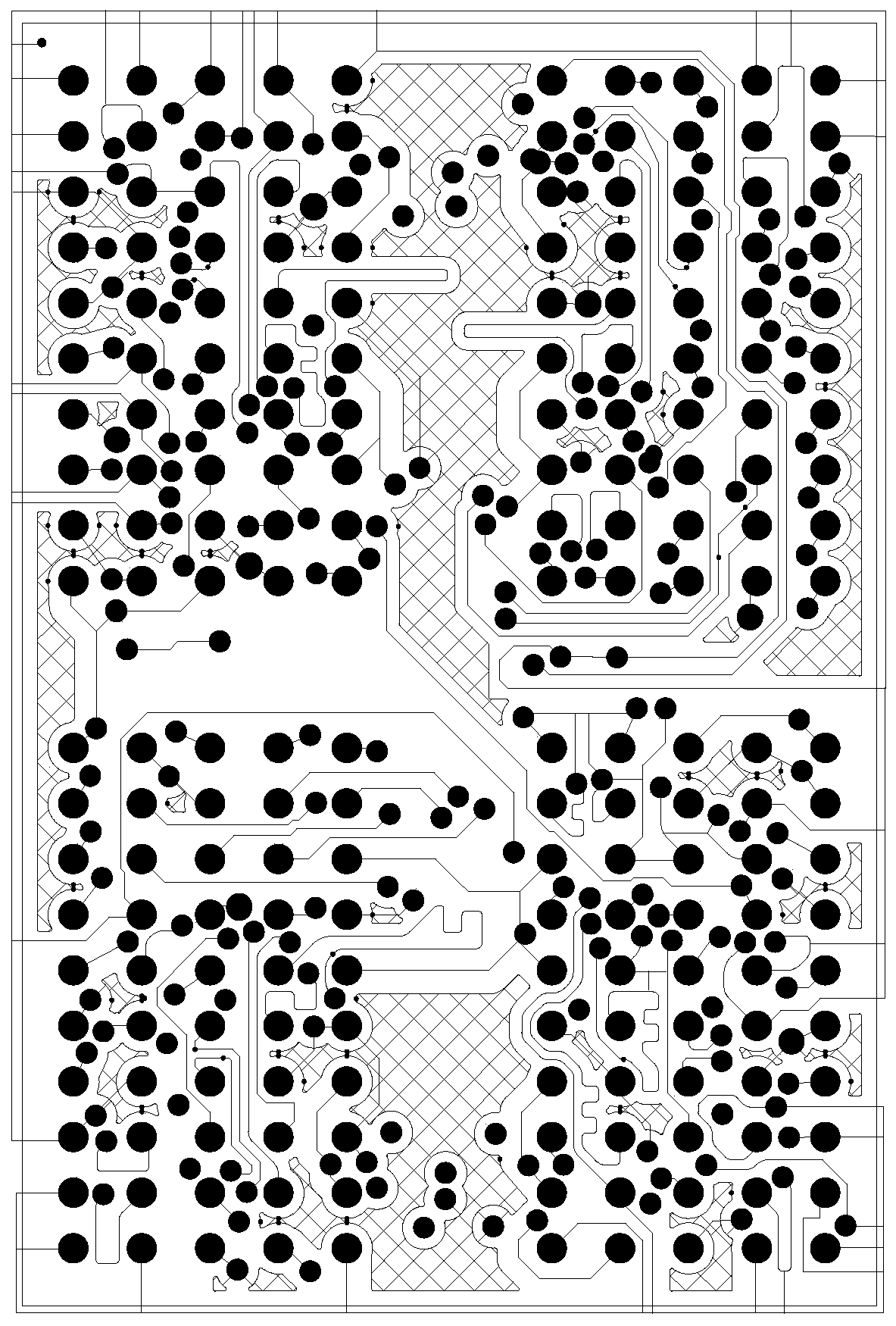

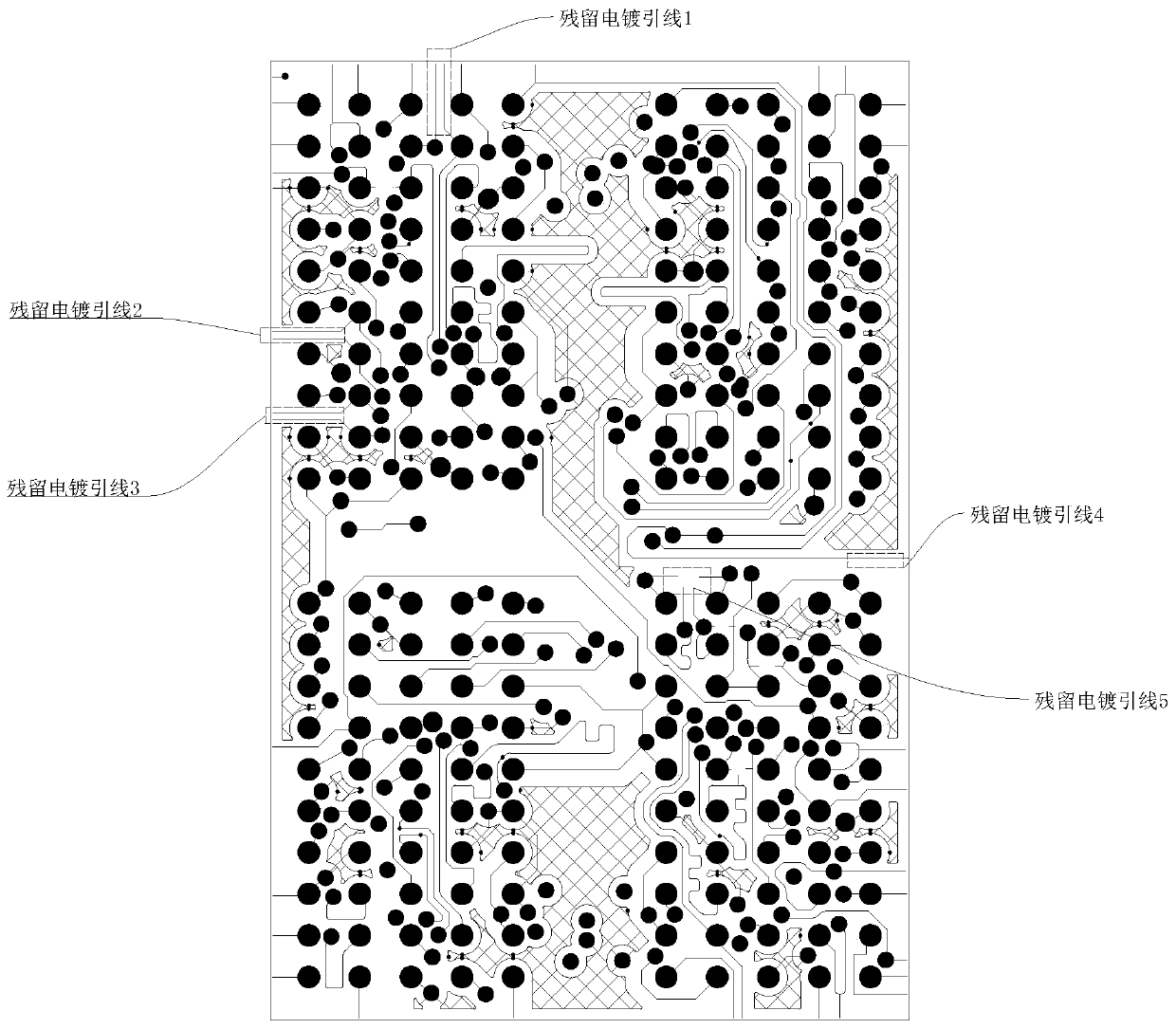

[0032] refer to Figure 5 , the present invention provides a method for designing an LPDDR substrate, comprising:

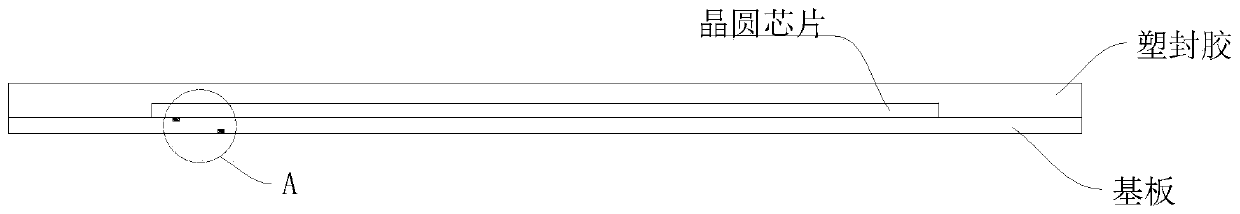

[0033] S1: Determining the chip packaging area 4 on the LPDDR substrate;

[0034] S2: A first etching area 1 and a second etching area 2 are respectively provided in the adjacent areas at both ends of the chip packaging area 4, wherein the first etching area 1 and the second etching area 2 are both used for setting the first electroplating lead 3, The first electroplating lead 3 is electrically connected to the circuit network to be electroplated on the LPDDR substrate.

[0035] In the embodiment of the present invention, the basic design process of the PCB board is as follows: the first step is the preliminary preparation, including the preparation of the component library and the schematic diagram; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com