Lactobacillus rhamnosus-contained probiotics fermented milk and preparation method therefor

A technology of Lactobacillus rhamnosus and fermented milk, which is applied in the field of probiotic fermented milk and its preparation, can solve the problems of sour taste, high acidity, and low viable count of Lactobacillus rhamnosus, and achieve slow change in acidity and good taste Moderate sweet and sour effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

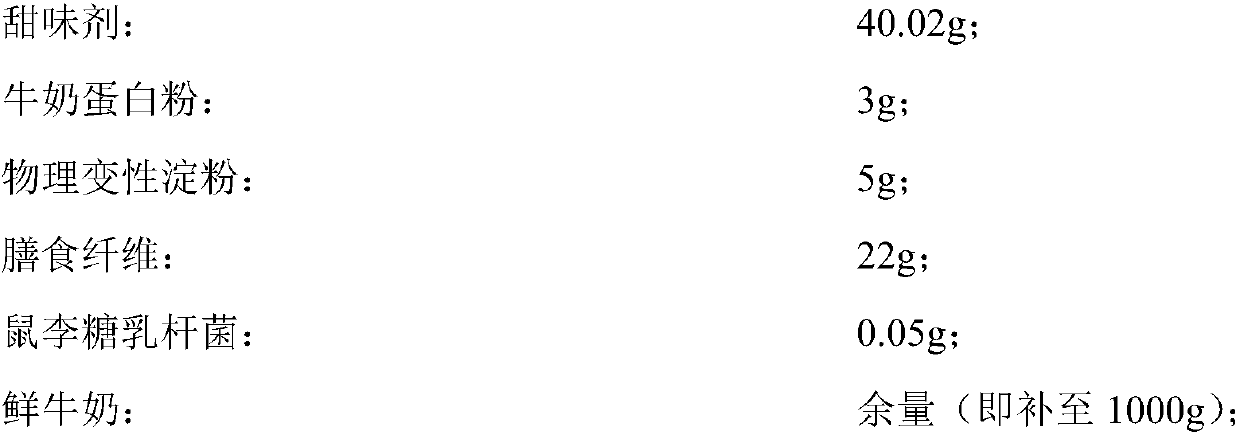

[0030] 1. Raw material formula (measured in 1000g):

[0031]

[0032] Wherein, the sweetener is erythritol 30g, xylitol 10g and steviol glycoside 0.02g, the dietary fiber is resistant dextrin 12g, polydextrose 10g;

[0033] 2. Preparation method:

[0034] (1) Standardization: standardize the milk;

[0035] (2) Ingredients: mix and circulate the standardized processed milk, white granulated sugar, milk protein, and chemically modified starch obtained in step (1) at 55°C for 20 to 30 minutes according to the ratio, so that they are evenly mixed to obtain a mixed material;

[0036] (3) Degassing: degassing the mixed material obtained in step (2) at 65°C and a negative pressure of -0.05MPa;

[0037] (4) Homogenization and sterilization: the degassed mixed material obtained in step (3) is homogenized and sterilized, the homogeneous primary pressure is 18MPa, the secondary pressure is 3MPa, and the temperature and time of sterilization are 95 ± 5℃ / 300s;

[0038] (5) Fermentat...

Embodiment 2

[0041] 1. Raw material formula (measured in 1000g):

[0042]

[0043] Wherein, the sweetener is 15g of erythritol, 15g of xylitol, 10g of maltitol and 0.004g of steviol glycoside, and the dietary fiber is 20g of polydextrose and 5g of fructooligosaccharide;

[0044] 2. Preparation method:

[0045] Method is with embodiment 1.

Embodiment 3

[0047] 1. Raw material formula (measured in 1000g):

[0048]

[0049] Wherein, the sweetener is 50g of isomaltulose and 0.005g of sucralose; the dietary fiber is 22g of polydextrose;

[0050] 2. Preparation method:

[0051] Method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com