Online filtering method and filtering device for water sample monitoring

A technology of filtering device and filtering method, which is applied in sampling device, preparation of test samples, filtering circuit, etc., can solve the problems of reducing the service life of analytical instruments, threats to analytical measuring instruments, affecting water quality measurement indicators, etc., so as to improve the service life. , the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

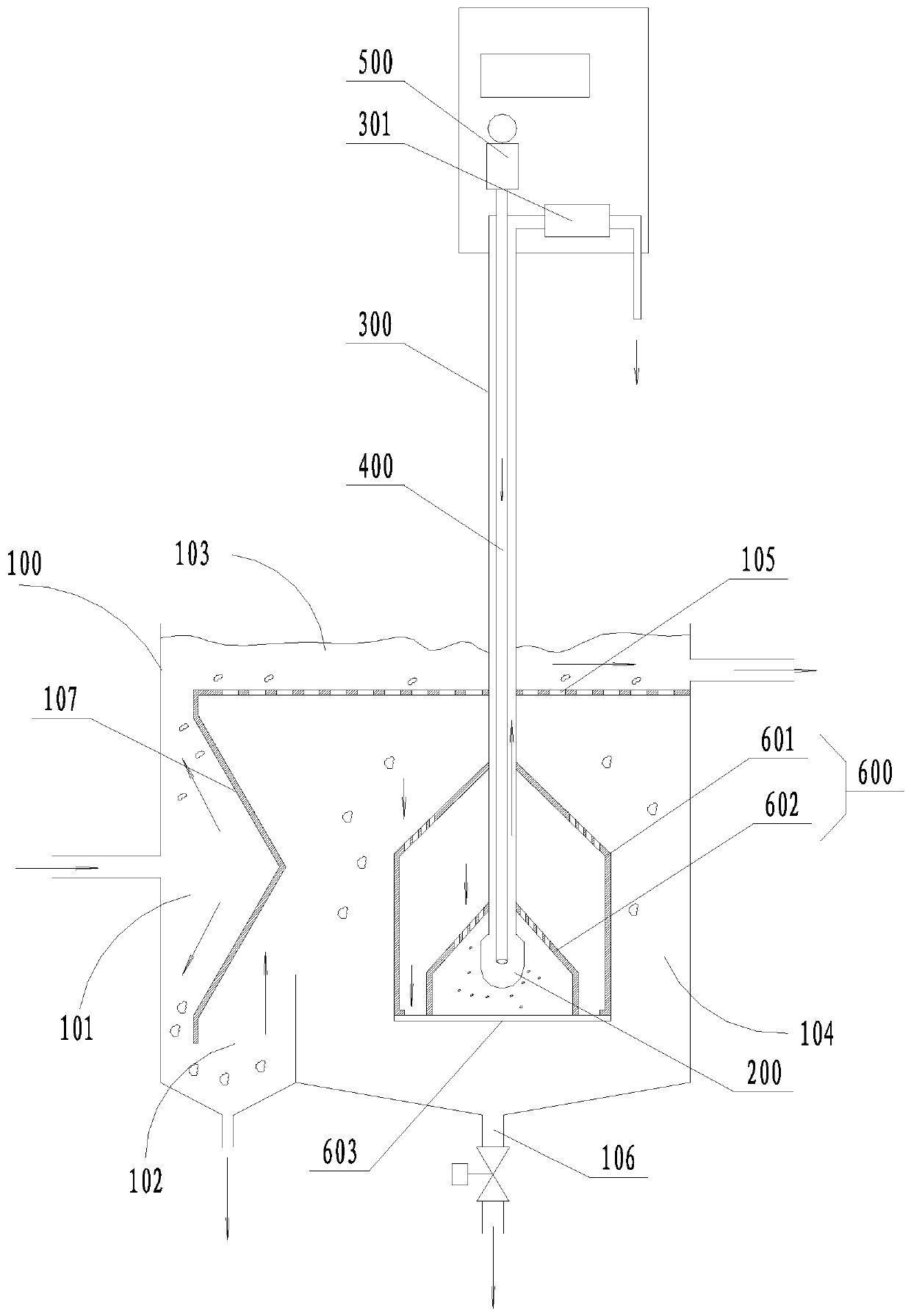

[0050] An online filtration method for water sample monitoring, comprising the following steps:

[0051] a. The water samples in the pipeline are drawn out online, and the water body is stratified by reducing the flow rate of the water body, the sedimentable particles in the water body sink and are discharged, and the floatable particles in the water body float up and are discharged with the continuous entry of the water body;

[0052] b. The suspended particles contained in the water body are filtered through the external light type metal filter membrane tube 200 to obtain water samples and lead them to the water quality analyzer for detection;

[0053] c. Perform reverse flushing of the external light type metal filter membrane tube 200 from the inside to the outside.

[0054] In order to realize the above online filtering method, this embodiment also includes an online filtering device for water sample monitoring.

[0055] The on-line filtration device includes a processin...

Embodiment 2

[0071] Based on the first embodiment, before step b, a primary filtration of the suspended particulates contained in the water body is also included to remove large suspended particulates.

[0072] The water sample filtering device also includes a filter chamber 600, which is closed and sleeved outside the external light type metal filter membrane tube 200, and is provided with filter holes for initially filtering suspended particles, which can protect the external light type metal filter membrane tube 200. , the bottom of the filter chamber 600 is provided with a one-way baffle 603 that can be opened when the backwash mechanism 500 is working.

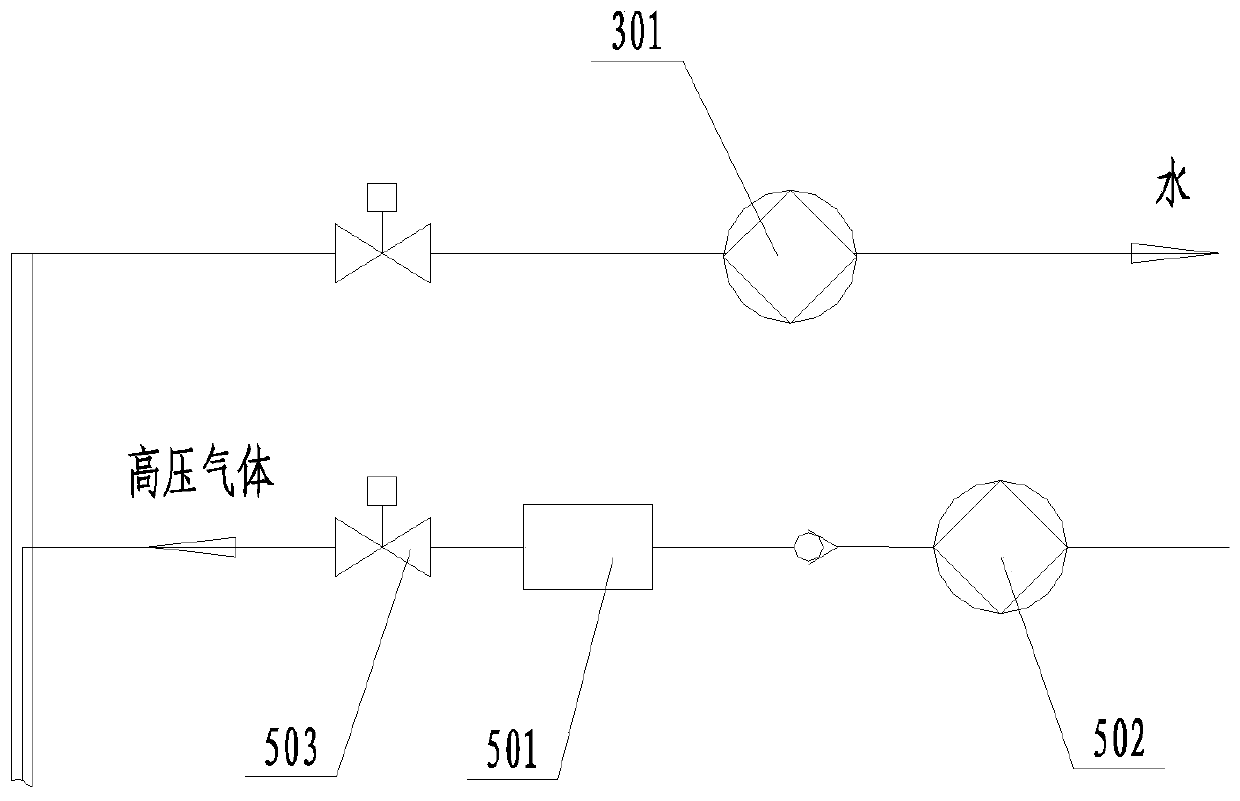

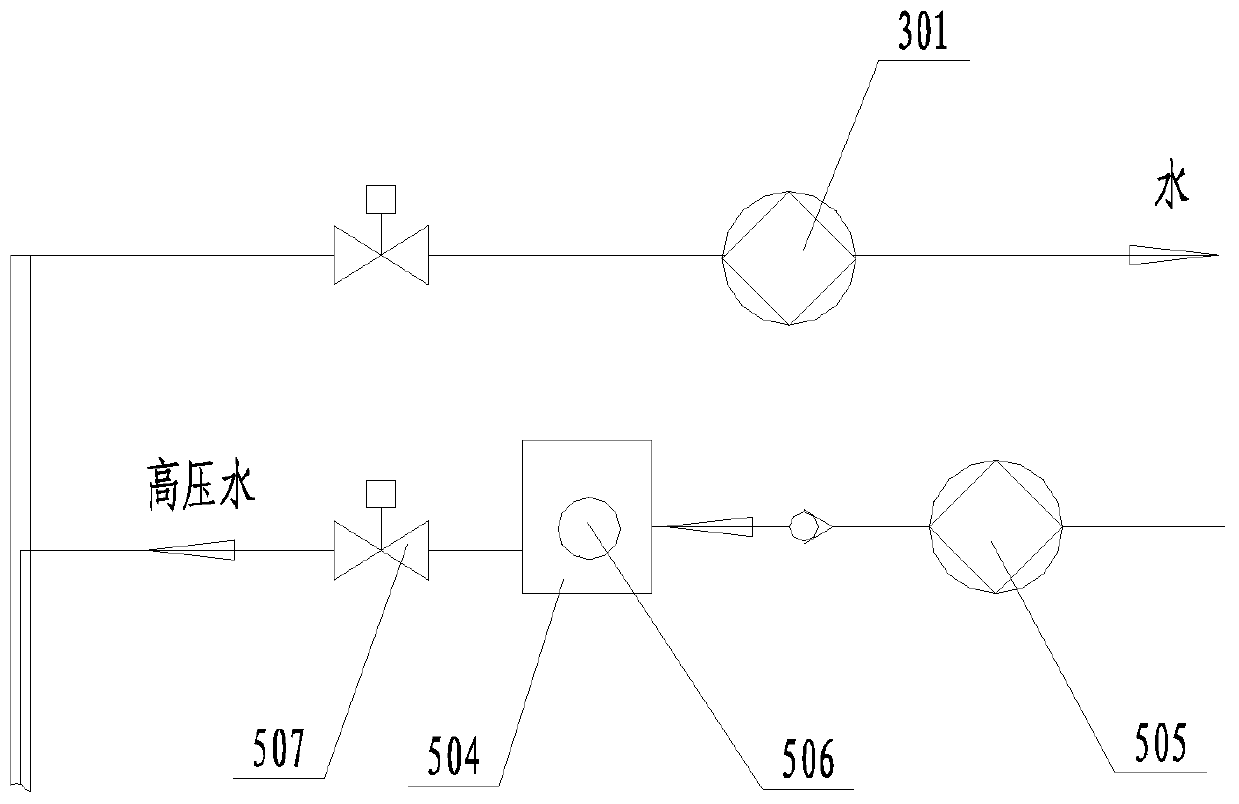

[0073] Such as Figure 4 As shown, one end of the one-way water baffle 603 is hinged to the warehouse body, and a tension spring 604 is fixed between the inner side of the water baffle 603 and the inner wall of the warehouse. When the backwash mechanism 500 works, the high-pressure gas Or the liquid overcomes the tension of the circl...

Embodiment 3

[0077] Based on the second embodiment, the filter chamber 600 includes a sheathed outer chamber body 601 and an inner chamber body 602, the outer chamber body 601 and the inner chamber body 602 are fixed with the maintenance tube 400, and the outer chamber body 601 and the inner chamber body 602 are fixed. There is a space between the bin bodies 602, and the upper end surfaces of the outer bin body 601 and the inner bin body 602 have filtering holes staggered up and down.

[0078] By staggering the filter holes on the outer bin body 601 and the inner bin body 602 up and down, through the cross-flow, the settleable particles entering through the outer bin body 601 will fall vertically under the action of gravity, and the corresponding inner bin body 602 will No filter holes are provided, so that the settleable particles can be kept out of the inner bin body 602 . In addition, through the filtering function of the filter hole, it can prevent floating and suspended particles from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com