Machining method of superheavy long shaft

A processing method and long-axis technology, applied in metal processing equipment, manufacturing tools, tool holder accessories, etc., can solve the problem of low processing accuracy, and achieve the effect of reducing weight, improving strength and rigidity, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

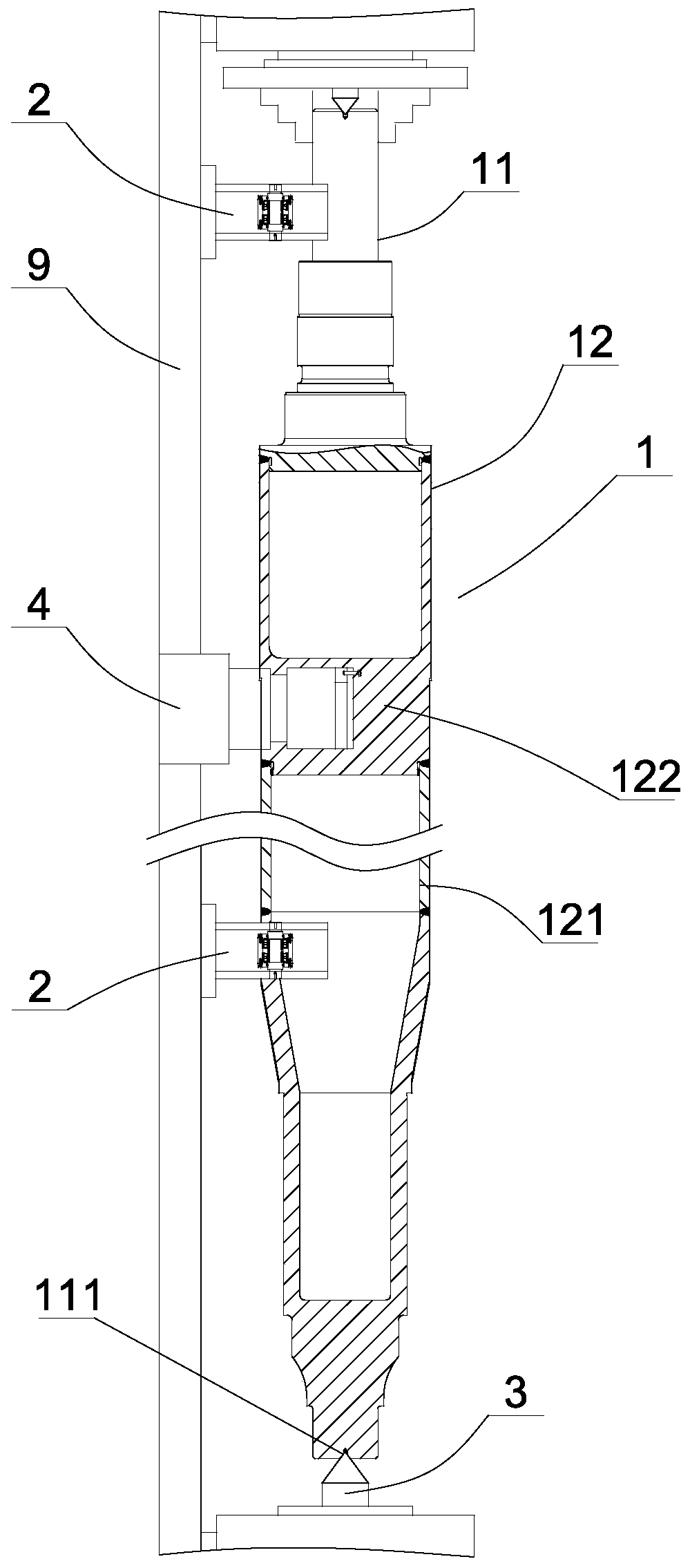

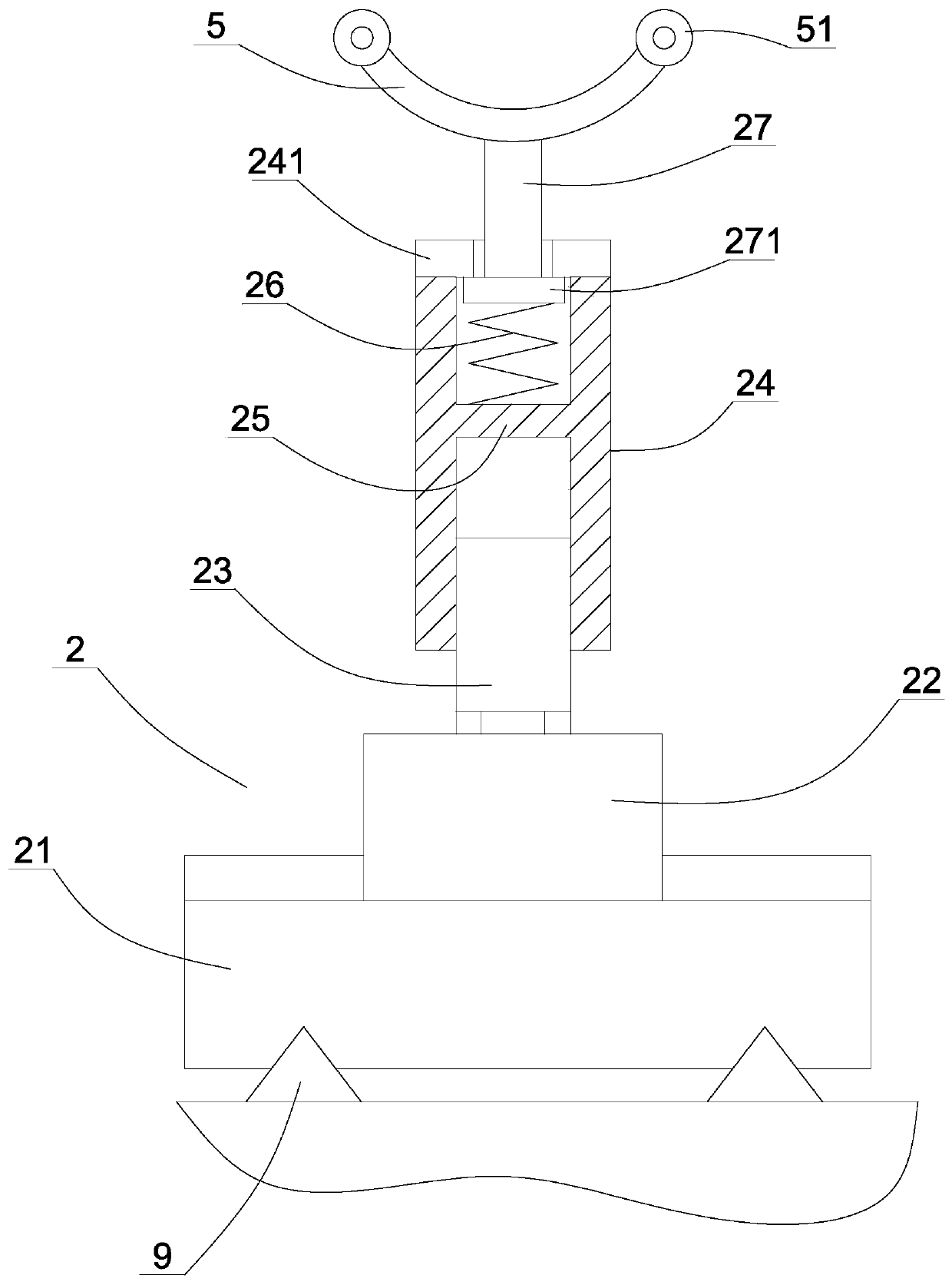

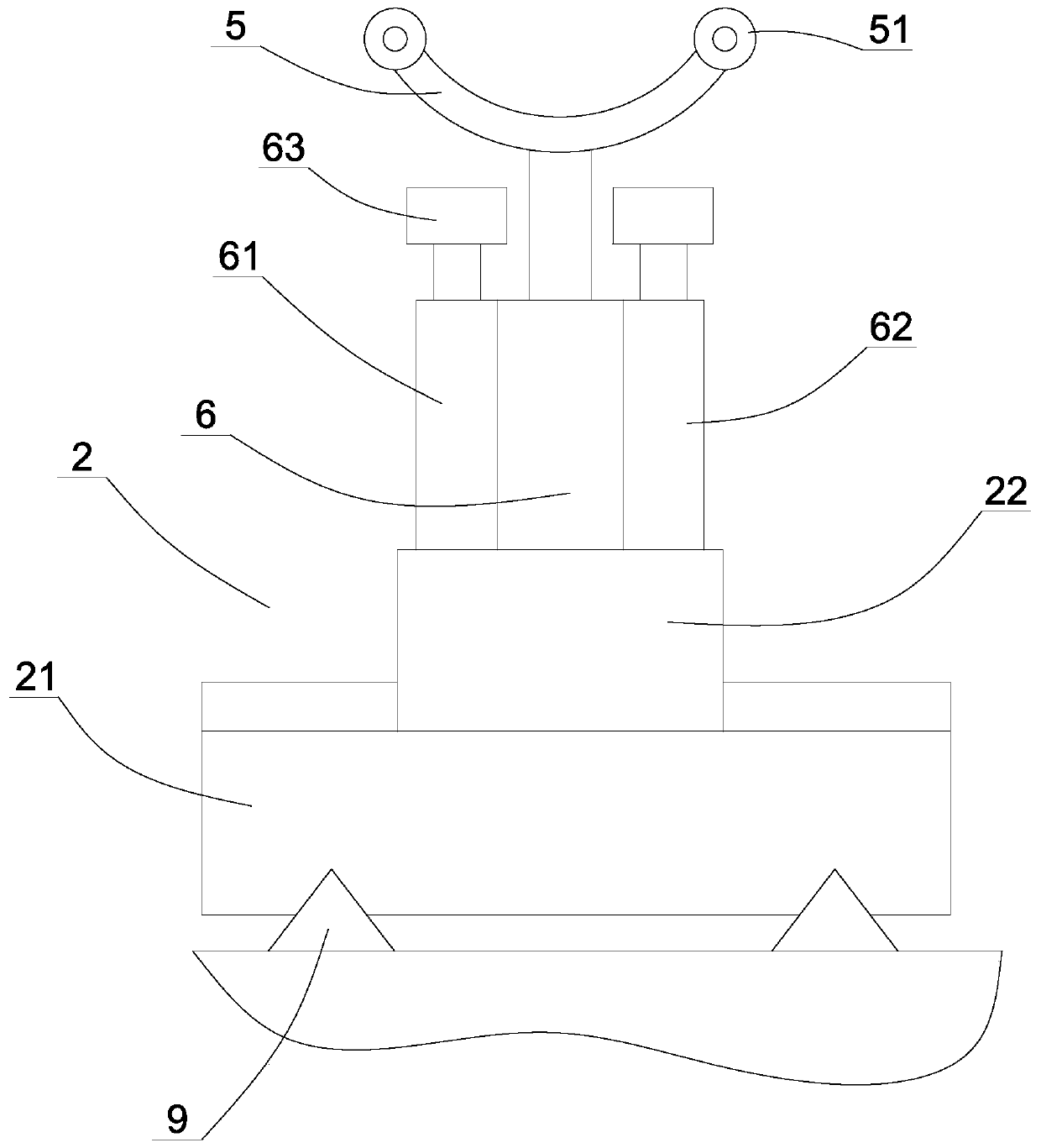

[0042] Such as figure 1 , figure 2 As shown, a processing method for an overweight long shaft, the super heavy long shaft 1 includes a support section 11 with a smaller diameter at both ends and a main body section 12 with a larger diameter in the middle, and a central hole 111 is set on the end surface of the support section. The super-heavy long shaft in the example is a shaft used for thermal power generation. The shaft length is 10m, the diameter of the support section is 300mm, the diameter of the main section is 750mm, and the material is 316 stainless steel. Specifically include the following steps:

[0043] a. First divide the main body section into two coaxially connected splicing sections 121, the splicing section is a round tube with a wall thickness of 40mm-60mm, and the inner hole at the end of one of the splicing sections is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com