Multifunctional woodwork processing equipment

A kind of processing equipment and multi-functional technology, applied in the direction of metal processing equipment, wood processing equipment, sawing equipment, etc., can solve the problem of single function, achieve the effect of simple operation, convenient use, and deburring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

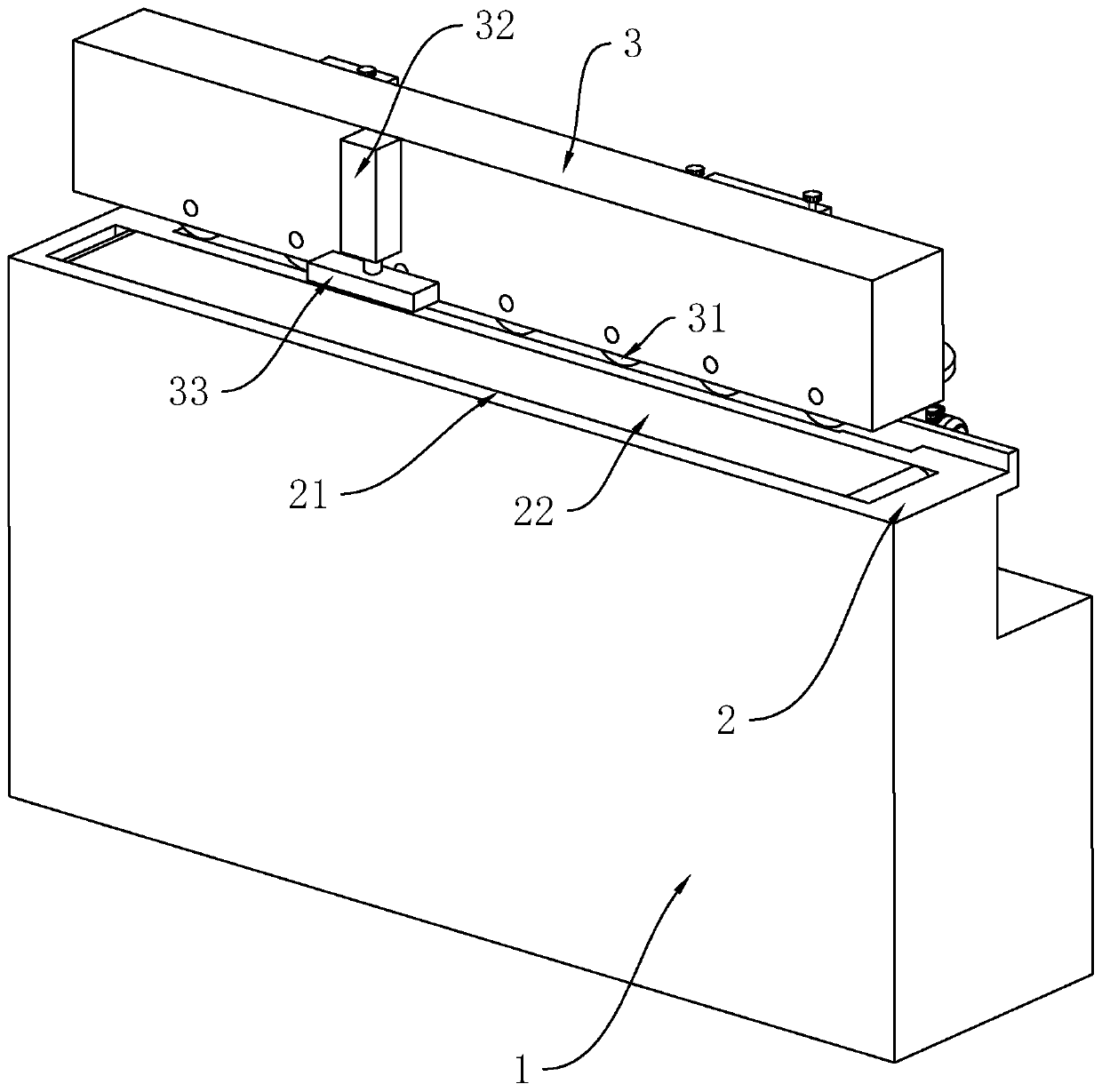

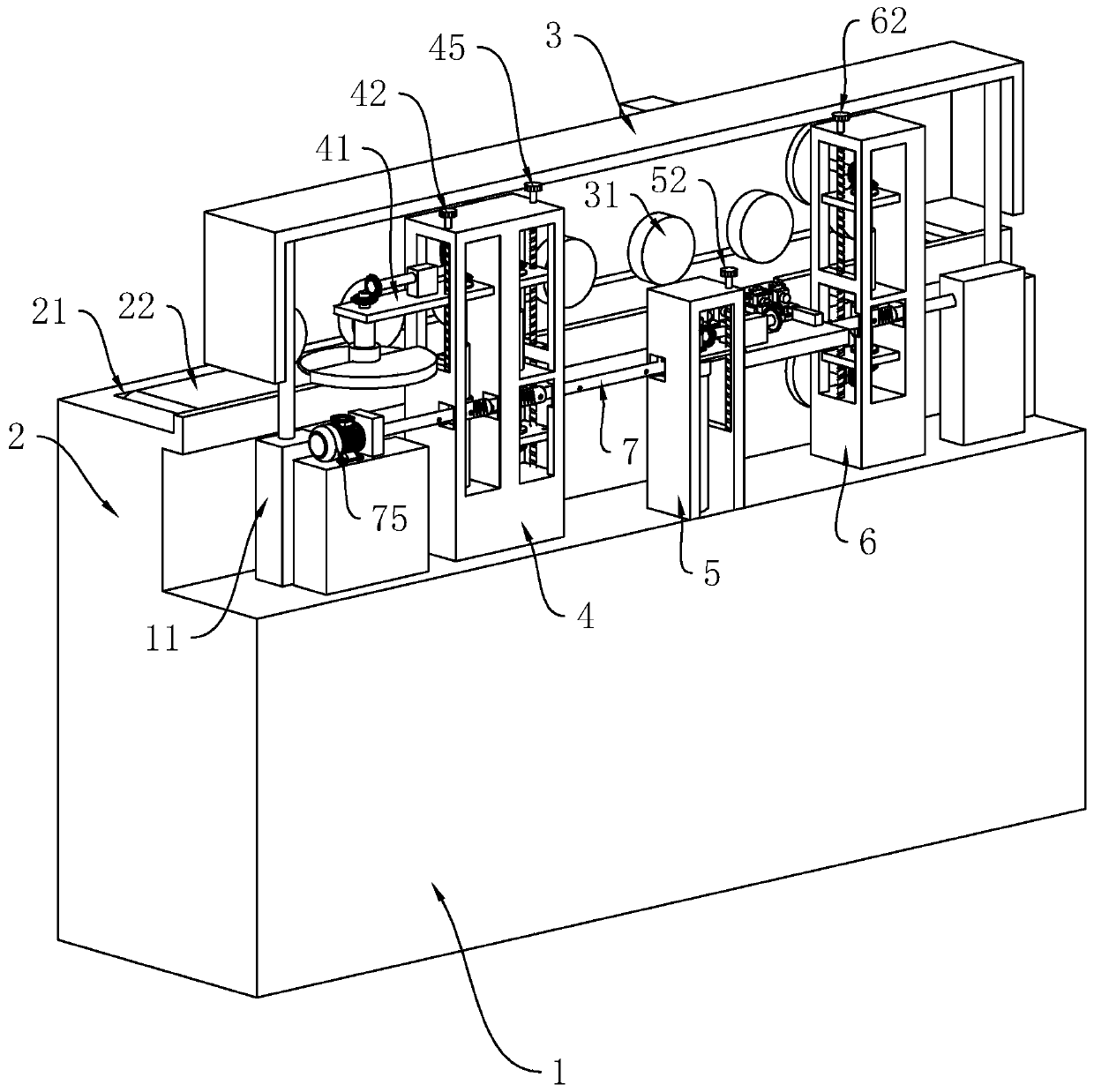

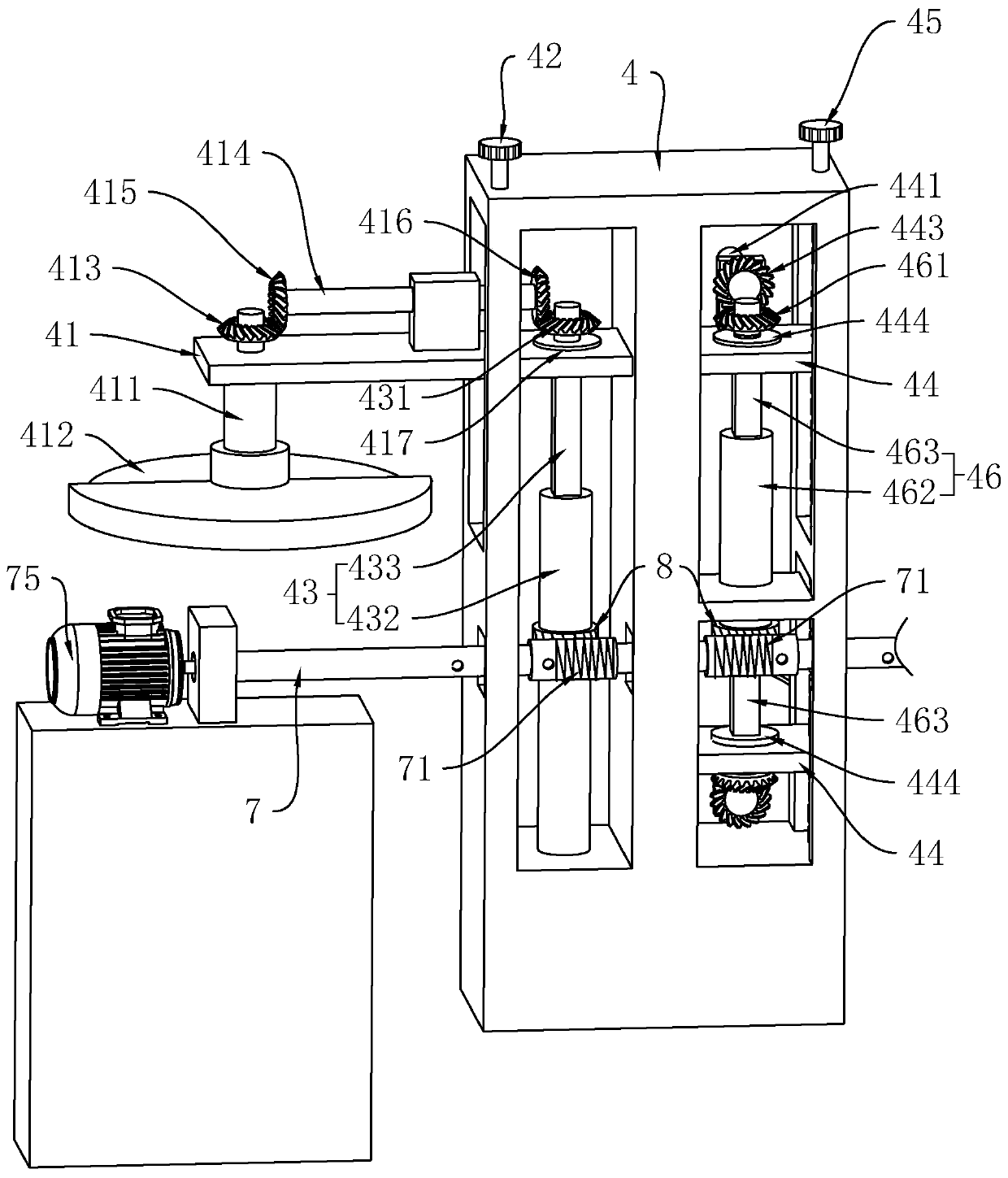

[0040] refer to figure 1 , is a kind of woodworking multifunctional processing equipment disclosed by the present invention, comprising a base 1, the base 1 has a cuboid structure, one side of the base 1 is fixedly connected with a transmission platform 2 along the length direction of the base 1, and the middle part of the transmission platform 2 is along the direction of the transmission platform 2 The length direction of the tank 21 is provided with a plurality of transmission rollers (not shown in the figure) whose axis direction is perpendicular to the length direction of the transmission table 2 along the length direction of the storage tank 21. Conveyor belt 22 is arranged, and the upper side of conveyer belt 22 is flush with the upper side of conveying platform 2 , and a servo motor capable of driving a conveying roller at the end of conveying belt 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com