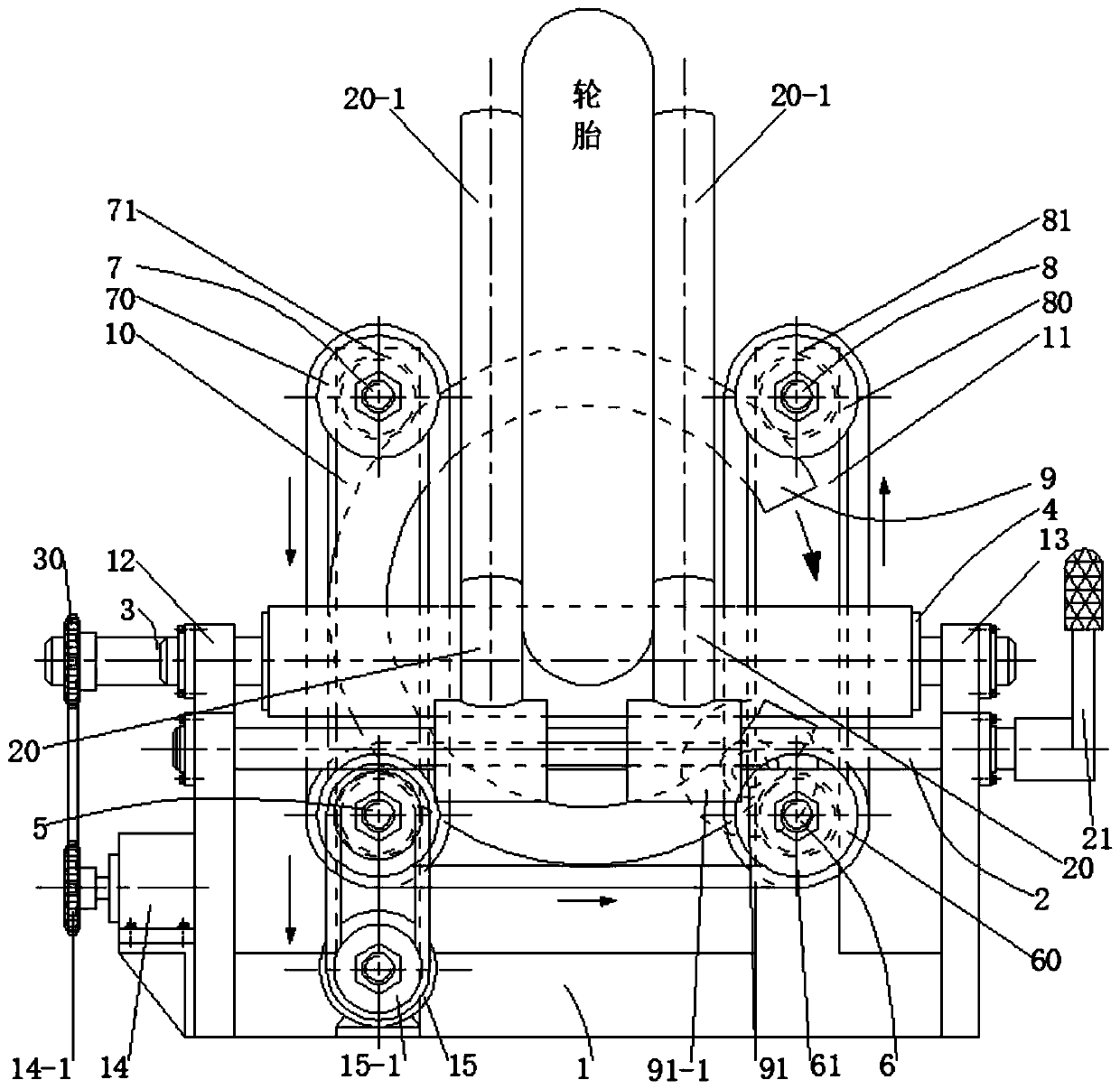

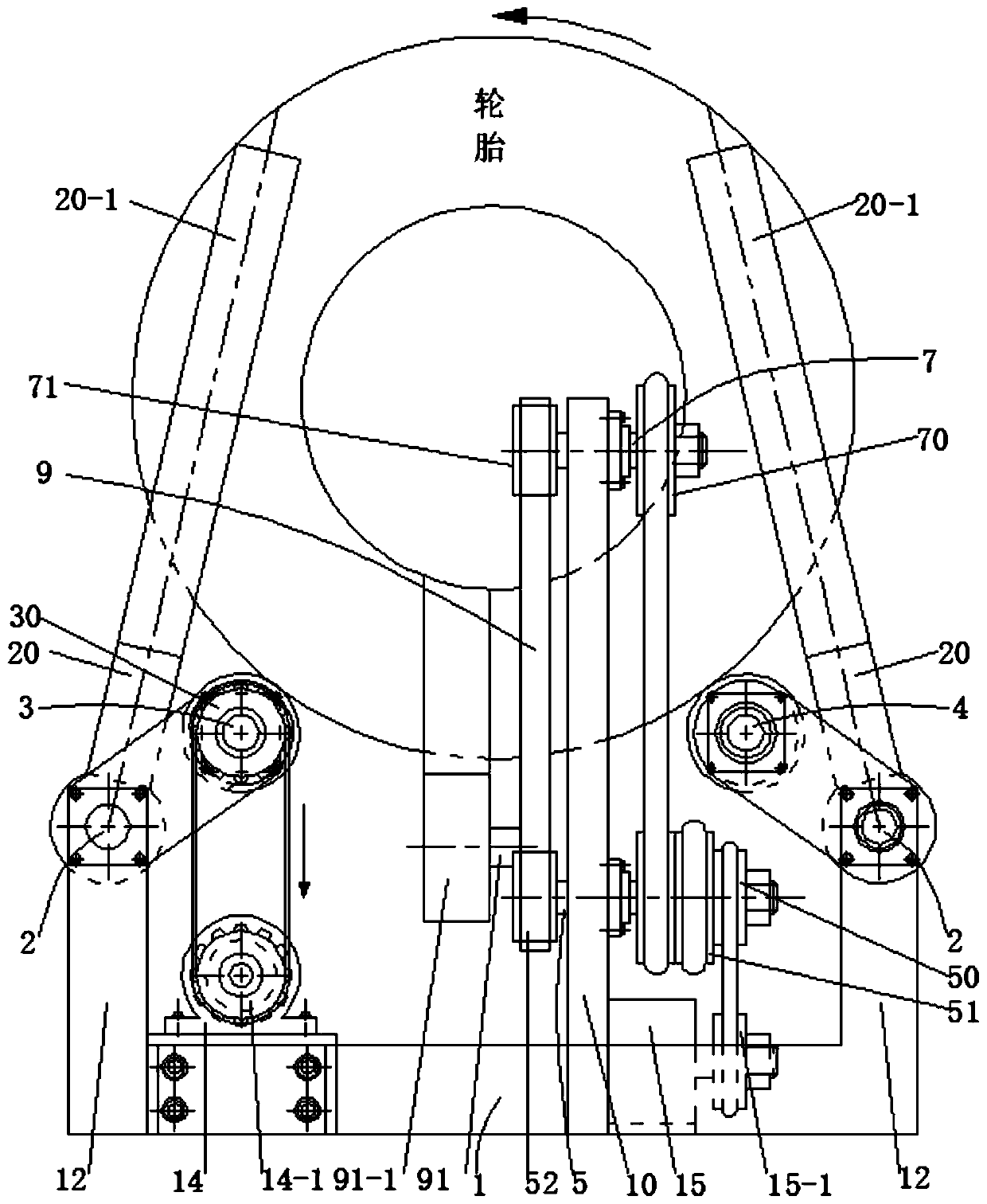

Tire laminating device on production line

A coating device and production line technology, applied in the direction of packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of affecting the appearance, easy to scatter, and affecting transportation, so as to avoid uneven coating, reduce rotation resistance, and ensure reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The tire laminating device on the production line first puts the deburred tire on the gap 90 on the turntable 9, so that the tire is supported by the driving roller 3 and the passive roller 4, and then manually pushes the wrench 21 inward, and the wrench 21 drives Rotating shaft one 2 rotates to the uppermost end with the stop bar 20, so that the tire is limited by the stop bar 20, then the film end on the film roller 91-1 is pasted on the tire outer wall, and then the motor one 14 and Motor II: 15 .

[0049] Motor one 14 drives sprocket one 14-1 to rotate clockwise, and sprocket one 14-1 drives sprocket two 30 to rotate clockwise through chain, and sprocket two 30 drives driving roller 3 to rotate clockwise, because driving roller 3 and driven roller 4. The outer wall is provided with a rubber film, and the rolling friction force generated by the driving roller 3 on the tire rubber drives the tire to rotate counterclockwise; at the same time, the motor two 15 drives th...

Embodiment 2

[0051] On the basis of Example 1, after the technical solution of the present invention completes the automatic coating operation of tires, the middle hole of the tires is not covered, which facilitates the stacking of multiple tires through columns and facilitates transportation; There are two limit rods 20, and the limit rods 20 rotate coaxially with the rotating shaft 12, and the ends of the rotating shaft 12 are fastened with a wrench 21 to ensure that the tire is driven to rotate by the driving roller 3 in a vertical state. The uniformity of the coating is guaranteed; the limit rod 20 is provided with a rotating sleeve, which reduces the rotation resistance of the tire and ensures the reliability of the driving roller 3 driving the tire to rotate; the outer wall of the driving roller 3 and the driven roller 4 A rubber film is provided to avoid the occurrence of non-uniform coating caused by slipping between the tire and the driving roller 3; the turntable 9 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com