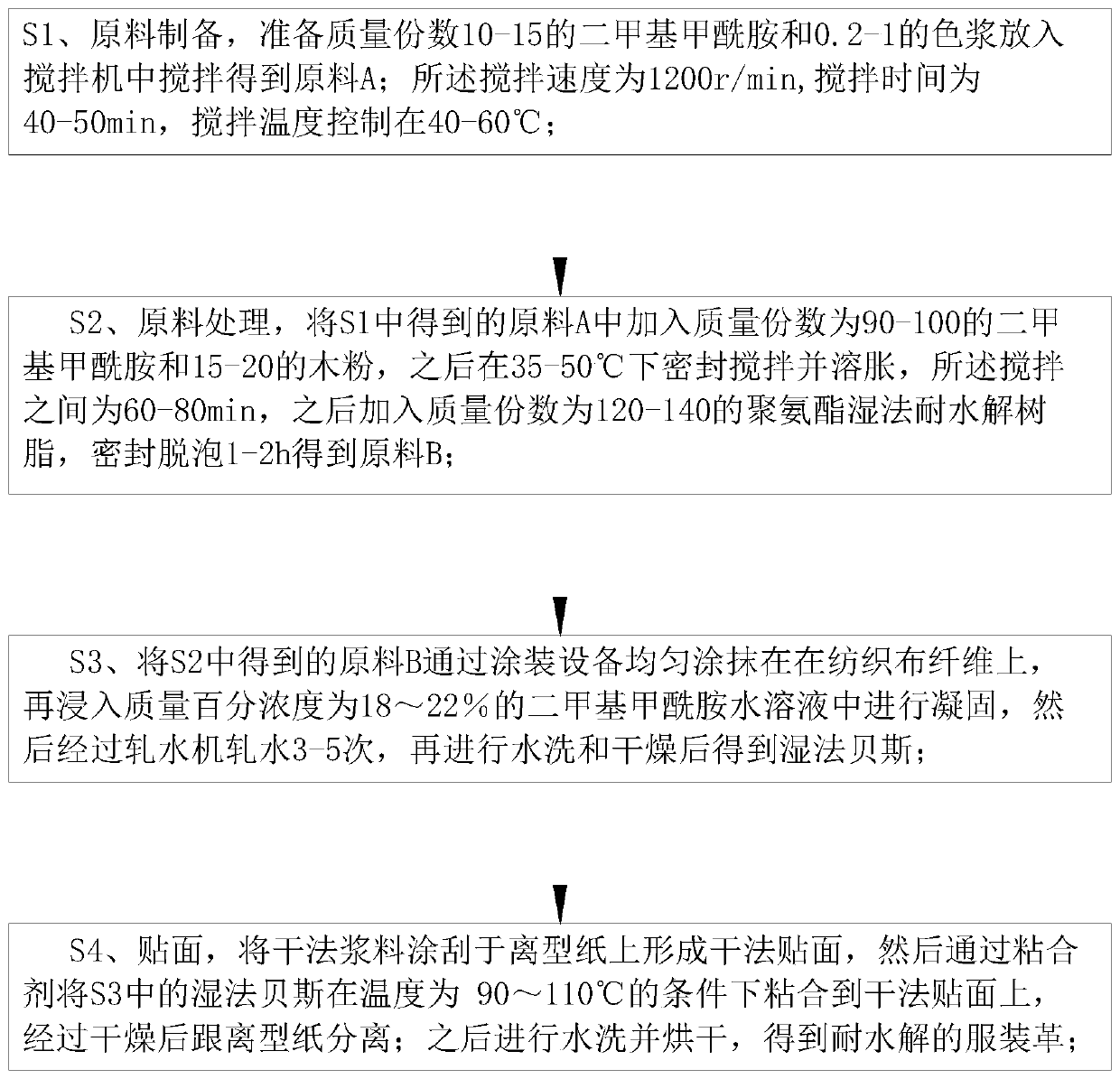

Method for manufacturing hydrolysis-resistant garment leather

A production method and garment leather technology, applied in liquid/gas/steam removal by scraping method, liquid/gas/steam removal by air jet method, textile and paper making, etc., can solve wrinkle friction, artificial leather breakage, short wearing time, etc. problem, achieve the effect of reducing discharge speed, increasing efficiency, and increasing wiper efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

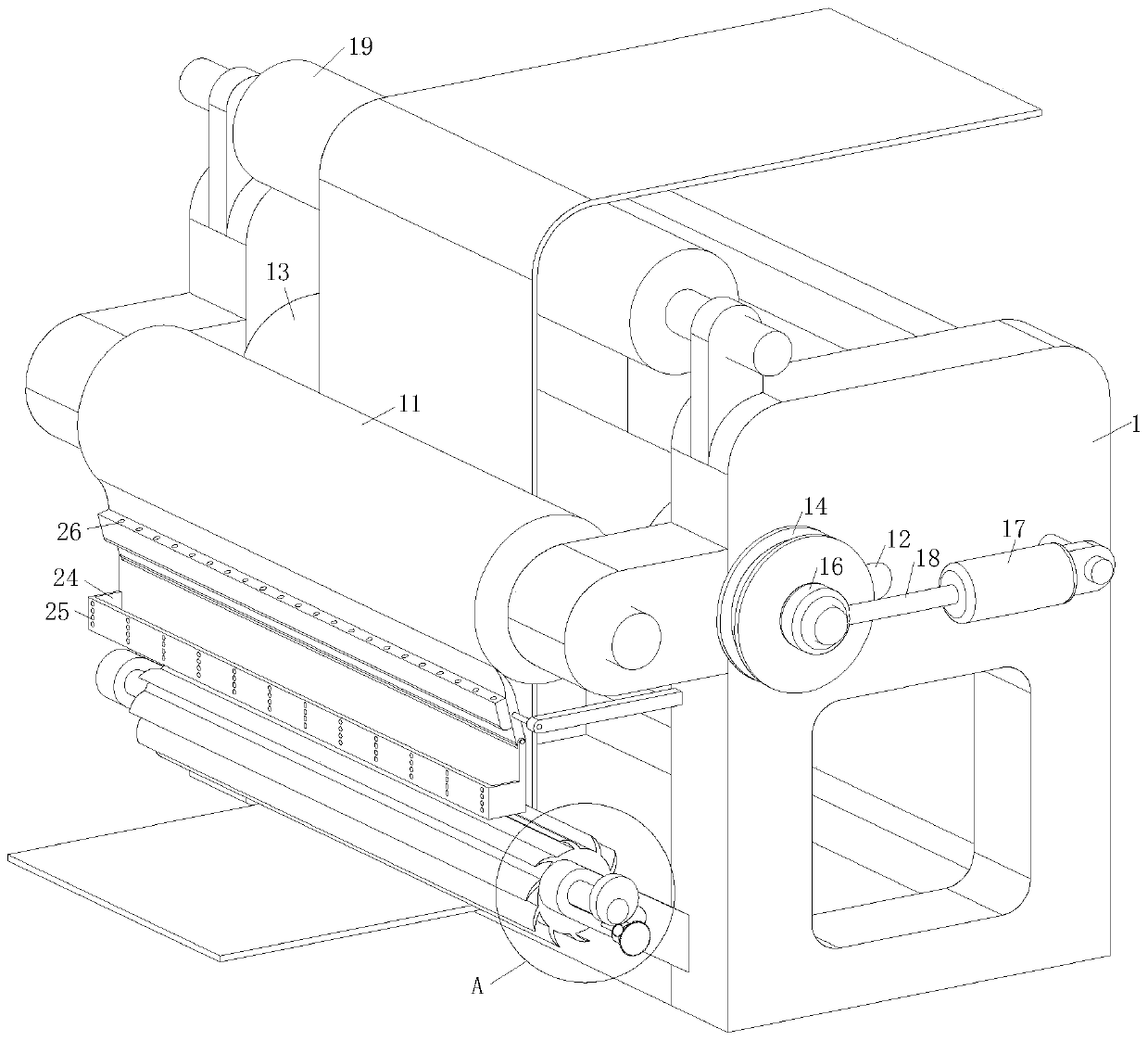

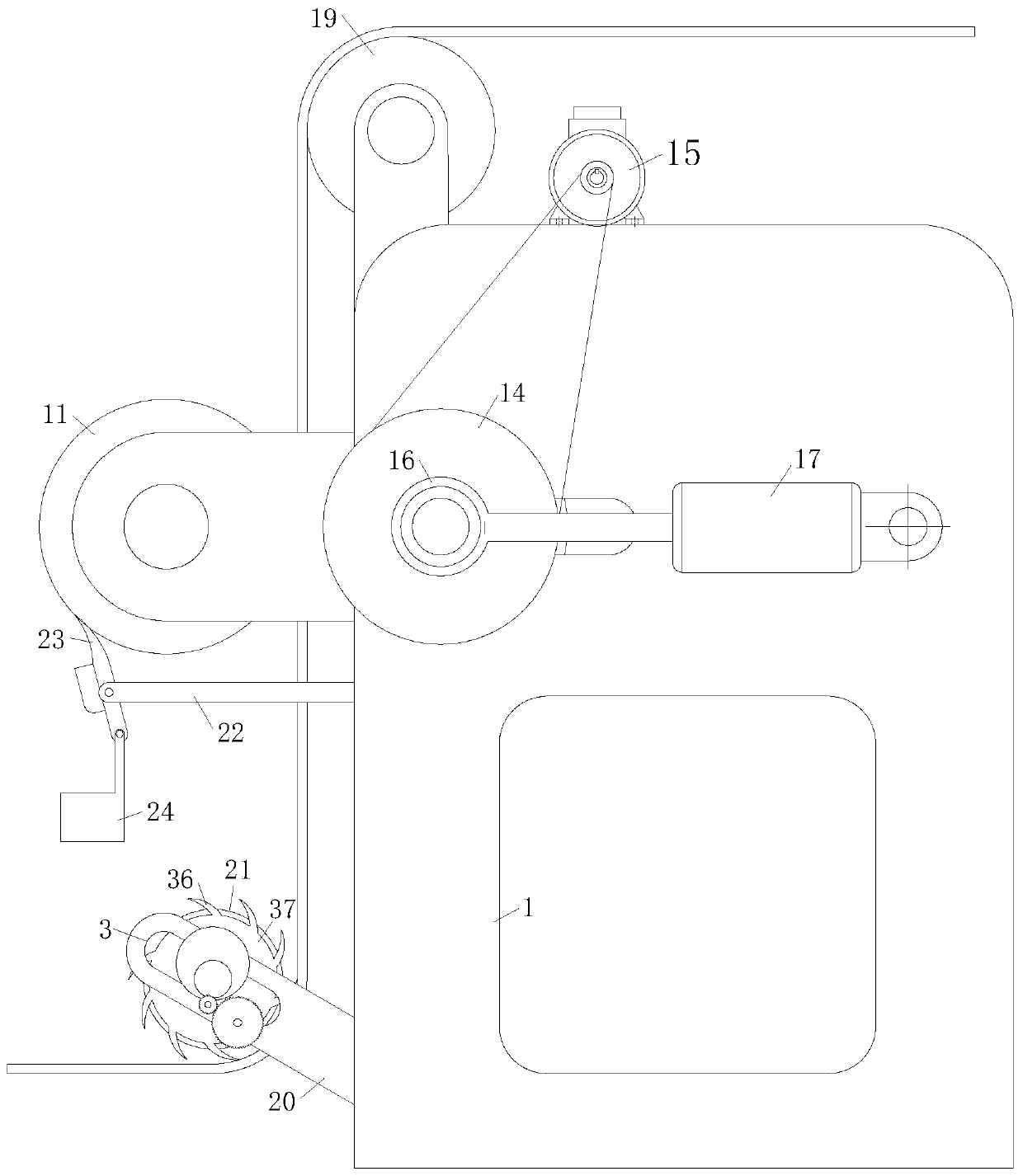

[0032] As an embodiment of the present invention, a pair of No. 2 brackets 22 is fixedly connected to the frame 1 at the corresponding position below the driven roller 11, and the end of the No. 2 bracket 22 away from the frame 1 is provided with a scraper 23. 23 is used to scrape off the moisture adhered on the driven roller 11, and further increase the efficiency of weaving water; through No. 2 support 22 and scraper 23, the water film adhered on the driven roller 11 is scraped off, reducing The content of residual moisture on the driven roller 11, and then reduce the residual moisture to enter the gap between the driving roller 13 and the driven roller 11 again with the rotation of the driven roller 11, so as to ensure the water rolling efficiency of the driven roller 11, and further increase the Efficiency of rolling water.

[0033] As an embodiment of the present invention, the middle part of the scraper 23 is hinged with the No. 2 bracket 22, and the bottom end of the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com