A kind of production technology of anti-myopia paper

A production process and anti-myopia technology, which is applied in the field of papermaking, can solve the problems of deforestation, environmental damage, and high production costs, and achieve the effects of reducing environmental pollution, increasing color fastness, and soft color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

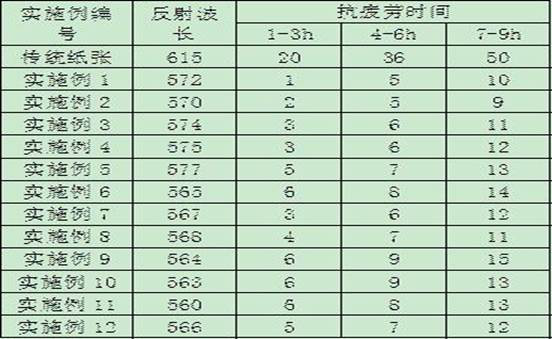

Examples

Embodiment 1

[0034] Embodiment 1: a kind of production technology of anti-myopia paper, comprises the following steps:

[0035] Step 1, preparing waste thin paper deinked pulp, coniferous wood pulp, and wheat straw pulp respectively;

[0036] Step 2, uniformly mix waste tissue paper deinking pulp, coniferous wood pulp, and wheat straw straw pulp to obtain a mixed pulp. The weight percentages of the three are: waste tissue paper deinking pulp 55%, coniferous wood pulp 15%, wheat straw Straw pulp is supplemented to 100%;

[0037] Step 3, passing the obtained mixed pulp through a pressure sieve, and then using a fiber separator to separate the mixed pulp into fibers, controlling the fiber purity to be greater than 95%, and the impurity removal rate to be greater than 95%;

[0038] Step 4: Add basic bright yellow, tartrazine and sunfast yellow to the separated fiber slurry, and the weight percentages of basic bright yellow, lemon yellow and lightfast yellow in the fiber slurry are 0.03%, 0.03...

Embodiment 2

[0046] Embodiment 2: A production process of anti-myopia paper. The difference from Embodiment 1 is that the percentages by weight of the three are: 60% of waste tissue paper deinking pulp, 13% of coniferous wood pulp, and supplemented by wheat straw pulp to 100%.

Embodiment 3

[0047] Embodiment 3: A production process of anti-myopia paper. The difference from Embodiment 1 is that the percentages by weight of the three are: 65% of waste tissue paper deinking pulp, 10% of coniferous wood pulp, and supplemented by wheat straw pulp to 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com