Burner for gas cooker

A technology for burners and gas stoves, which is applied in the direction of gas fuel burners, burners, and non-flammable liquid/gas transportation, etc., can solve the problems of uneven flame, large channel resistance, and uneven gas pressure, and reduce local resistance. Loss, improve mixing uniformity, reduce the effect of resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

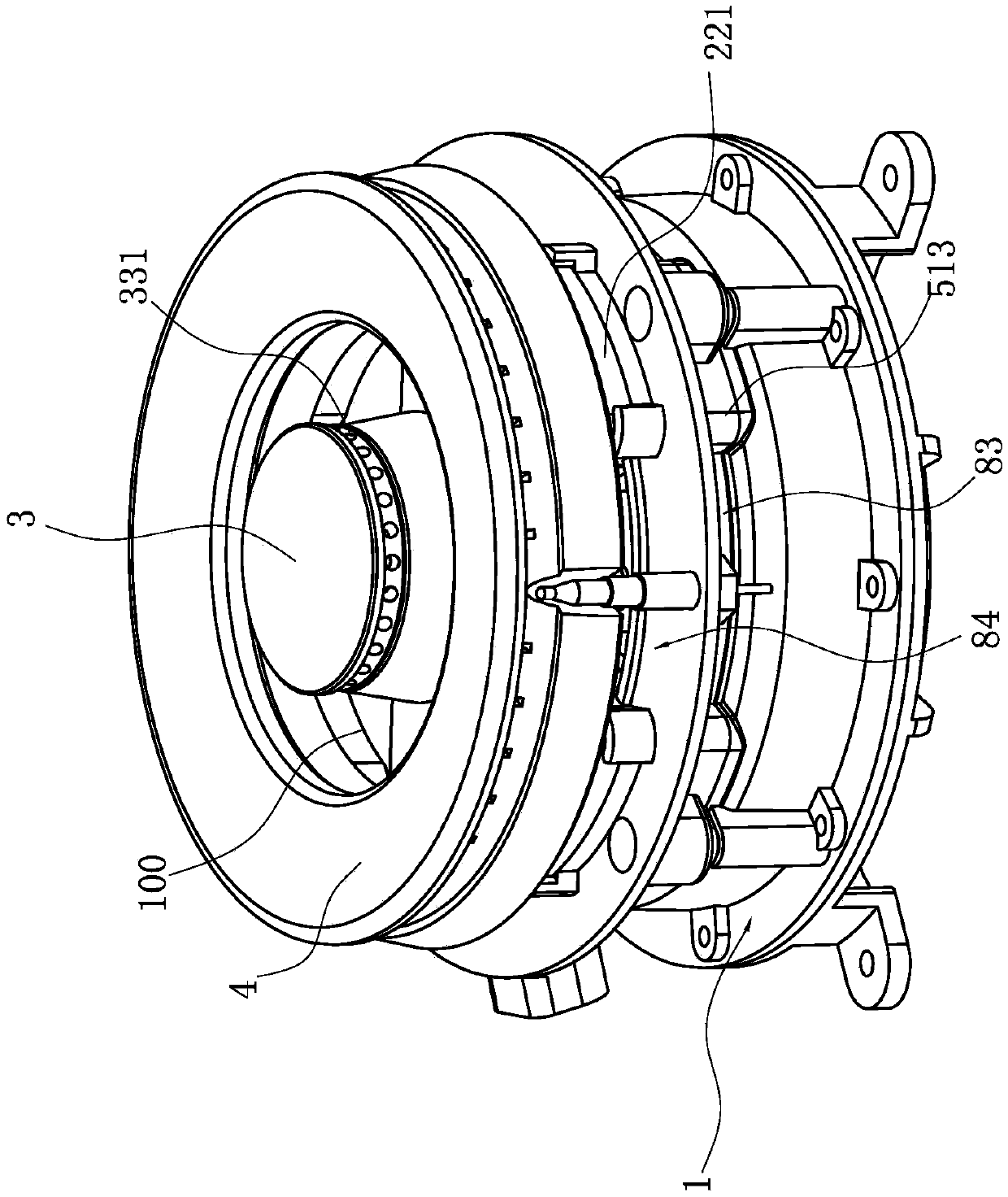

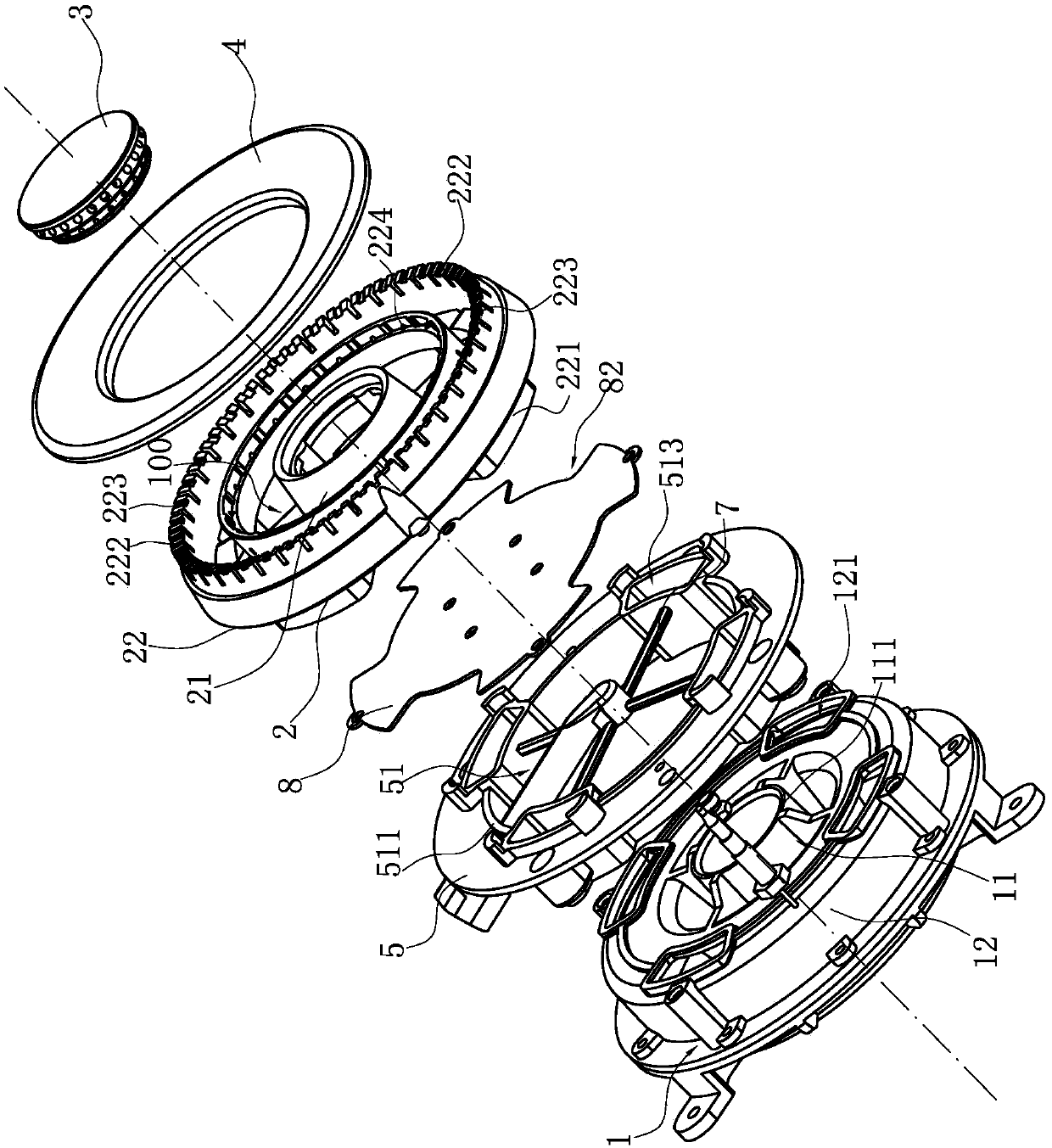

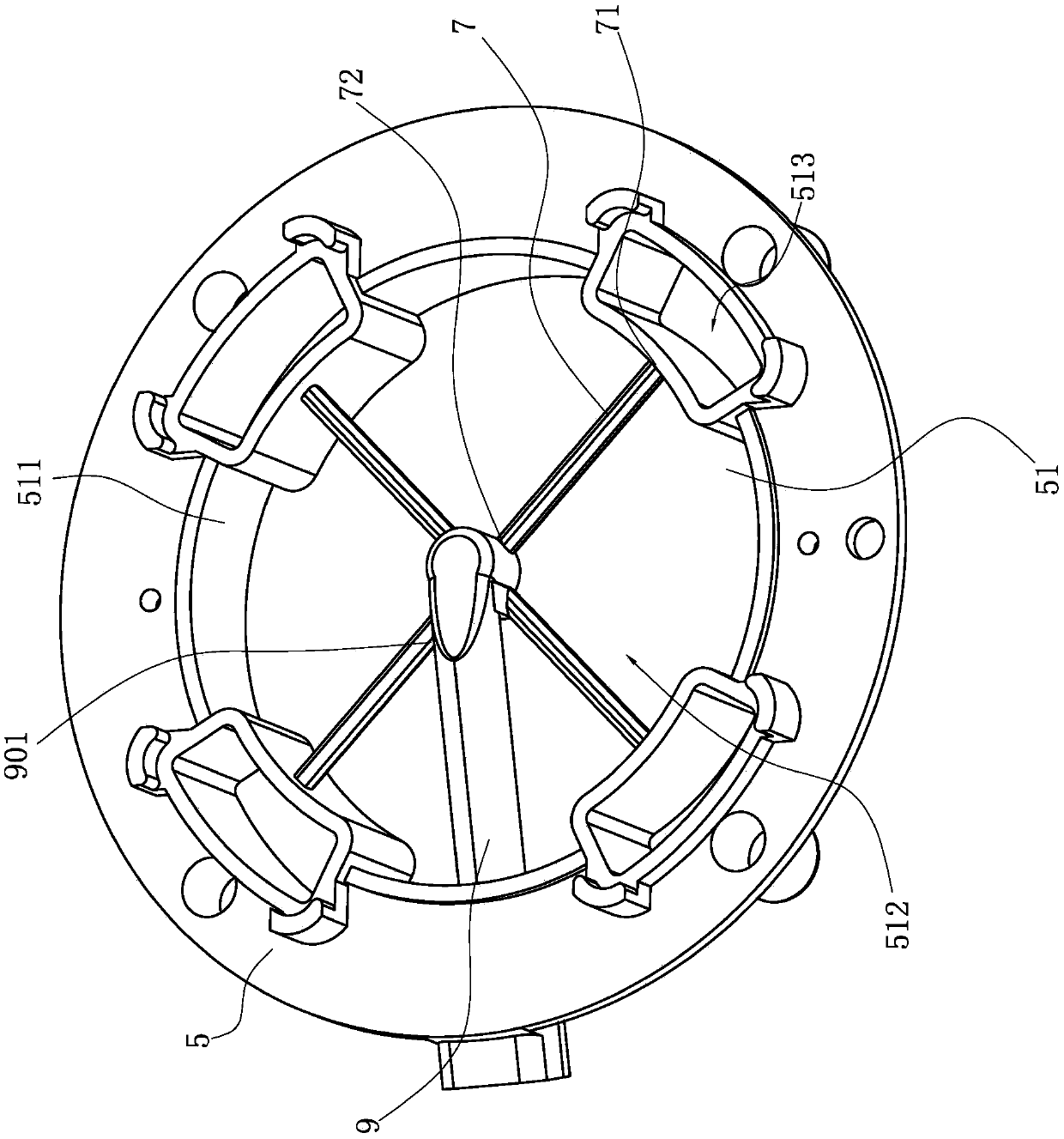

[0040] Such as Figure 1-9 As shown, it is the best embodiment of the present invention, the burner used for the gas cooker can be applied to the traditional upward air-intake burner and can also be applied to the Italian Sabaf burner such as Europe, which is used for the combustion of the gas cooker The device includes a base 1 of a sandwich structure, the base 1 includes a central cavity 11 and a peripheral cavity 12 surrounding the cavity 11, and the top wall of the peripheral cavity 12 has at least two through holes in the circumferential direction 121, and the central position of the concave cavity 11 has an opening upwards, a vertical second injection channel 111, the second injection channel 111 communicates with the peripheral chamber 12, and the first connecting body arranged on the base 1 5. The first connecting body 5 includes a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com