Metallographic corrosion method for Hastelloy C-276 and 304 stainless steel laser welded joint

A technology of 304 stainless steel and C-276, applied in the field of metallographic corrosion of corrosion-resistant dissimilar alloy welded joints, can solve the problems of poor observation effect, poor corrosion of 304 stainless steel, corrosion of 304 stainless steel, etc. Clear grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] First, at a room temperature of 20-22 °C, use a straw to absorb a small amount of aqua regia solution to corrode the welded joints of the sample, and let the corrosive liquid slowly flow along the surface of the sample to corrode, and the corrosion time is 10s; then rinse with clean water and dry;

[0028] Then at room temperature of 20-22 °C, put the sample into saturated oxalic acid solution to carry out electrolytic corrosion on the welded joint, connect the welded joint of the sample to the anode of the electrolysis device, connect the aluminum alloy electrode to the cathode of the electrolysis device, and set the electrolysis voltage. For 8V, the corrosion time is 20s, then rinse with clean water and dry.

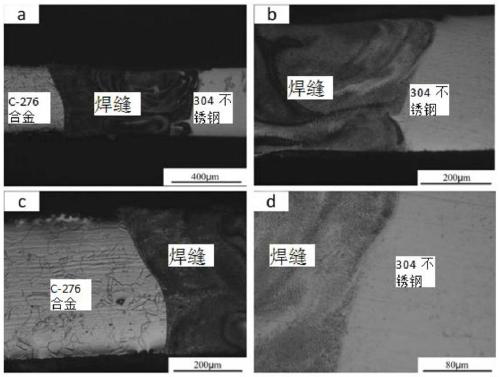

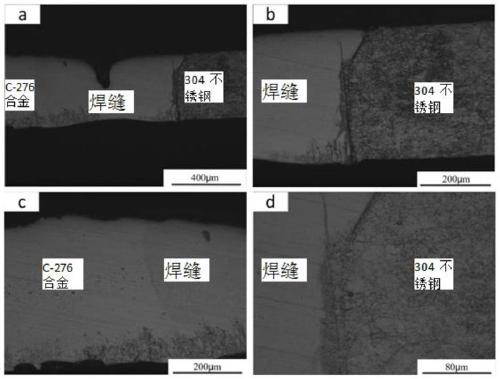

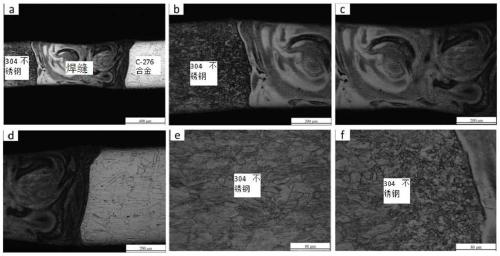

[0029] attached image 3 The metallographic microstructures of Hastelloy C-276 and 304 stainless steel obtained in this example are given by image 3 It can be seen that the grain boundary outline of its structure is clear, image 3 (e) is the metallographic p...

Embodiment 2

[0032] First, at room temperature of 20-22 °C, use a straw to absorb a small amount of aqua regia solution to corrode the welded joints of the sample, and let the corrosive liquid slowly flow along the surface of the sample to corrode, and the corrosion time is 11s; then rinse with water and dry;

[0033] Then at room temperature of 20-22 °C, put the sample into saturated oxalic acid solution to carry out electrolytic corrosion on the welded joint, connect the welded joint of the sample to the anode of the electrolysis device, connect the aluminum alloy electrode to the cathode of the electrolysis device, and set the electrolysis voltage. It is 10V, the corrosion time is 21s, then rinse with clean water and blow dry.

Embodiment 3

[0035] First, at a room temperature of 20-22 °C, use a straw to absorb a small amount of aqua regia solution to corrode the welded joints of the sample, and let the corrosive liquid slowly flow along the surface of the sample to corrode, and the corrosion time is 12s; then rinse with water and dry;

[0036] Then at room temperature of 20-22 °C, put the sample into saturated oxalic acid solution to carry out electrolytic corrosion on the welded joint, connect the welded joint of the sample to the anode of the electrolysis device, connect the aluminum alloy electrode to the cathode of the electrolysis device, and set the electrolysis voltage. For 9V, the corrosion time is 22s, then rinse with clean water and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com