Sizing yarn surface coating effect characterization method and sizing yarn levelness image acquisition device

A surface coating and sizing technology, which is applied in the field of textile sizing, can solve the problems of limited resolution of ordinary optical microscopes, damage to the integrity of the size film on the surface of sizing, blurred images of sizing slices, etc., to improve sample quality, The effect of broadening the meaning of actual production and improving the accuracy and accuracy of evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

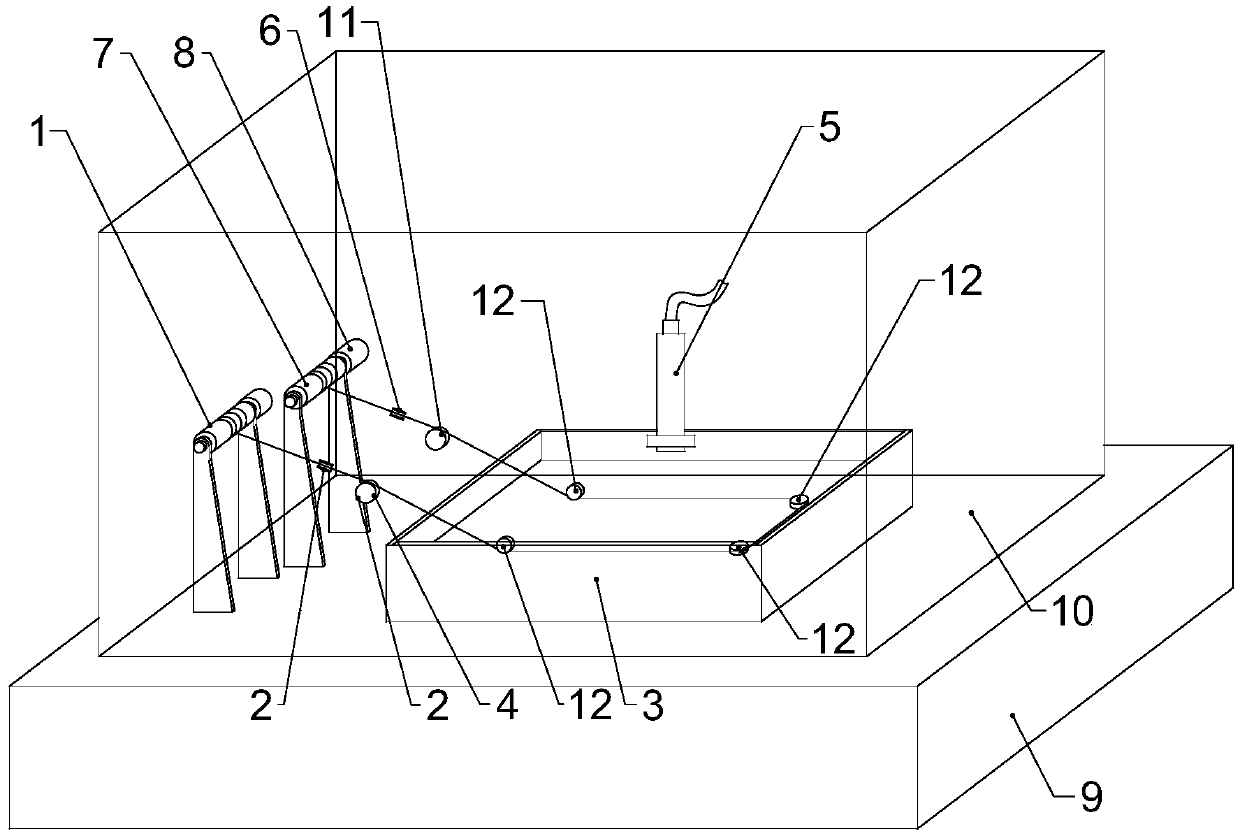

[0038] This embodiment takes figure 1 A sizing evenness image acquisition device as shown is used as the basis for implementation, and the method for characterizing the coating effect of sizing surface is described in detail, and the method includes the following specific steps:

[0039] (1) a color developer is configured in the solution tank 3;

[0040] (2) Place the bobbin wound with sizing on the unwinding device 1, and pull the yarn end such as figure 1 As shown, it is introduced into the solution tank 3 through the introduction roller 4, and then the inlet and outlet rollers 11 are exported to the solution tank 3 and wound on the bobbin on the winding device 7, so that part of the sizing is immersed in the developer, so that the sizing on the sizing The sizing film reacts with the color developer to develop color, in order to prolong the soaking time and running length of the sizing in the solution tank 3, and reduce the size of the solution tank 3 as far as possible, t...

Embodiment 2

[0056] Such as figure 1 A sizing image acquisition device shown includes a stage 9, a solution tank 3 placed on the stage 9, an introduction roller 4 that guides the sizing into the solution tank 3, and guides the sizing to leave the solution tank 3, the lead-out roller 11 of 3, the ultra-depth-of-field microscope 5 erected above the solution tank 3, the yarn-in tension control device 2 arranged on the upstream side of the lead-in roller 4, the yarn-out tension control device 6 arranged on the downstream side of the lead-out roller 11, the unwinding Device 1, winding device 7, and black box, are used to hold developer in the solution tank 3, and described unwinding device 1 and winding device 7 are arranged on the stage 9 outside solution tank 3, unwinding device 1 is located upstream of the yarn tension control device 2, and the winding device 7 is located downstream of the yarn tension control device 6. The black box 10 covers the solution tank 3 , and the lens of the ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com