Multilayer PCB differential eddy current detection sensor

A technology for detecting sensors and differential eddy currents, used in instruments, measuring devices, scientific instruments, etc., can solve the problems of poor lift-off effect detection, difficult placement of yokes, and poor detection effects, and achieve effective lift-off. Small, easy to detect, and the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

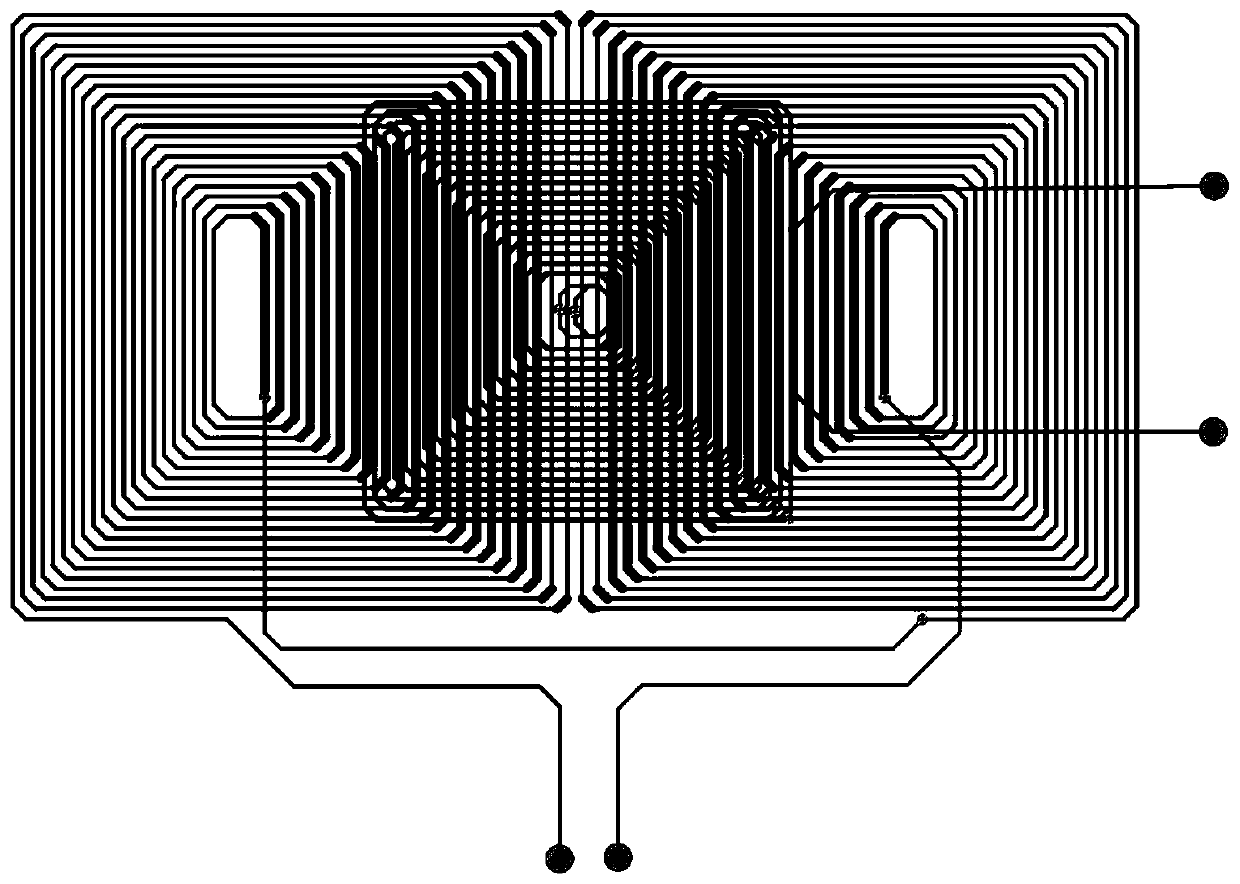

[0032] figure 1 It is a front view of a specific embodiment structure of a multi-layer PCB eddy current detection sensor of the present invention.

[0033] In this example, if figure 1 As shown, a multi-layer PCB differential eddy current detection sensor of the present invention includes: an excitation coil and four layers of receiving coils connected in series, and the central axes of the excitation coil and the receiving coil are the same; each component will be described in detail below.

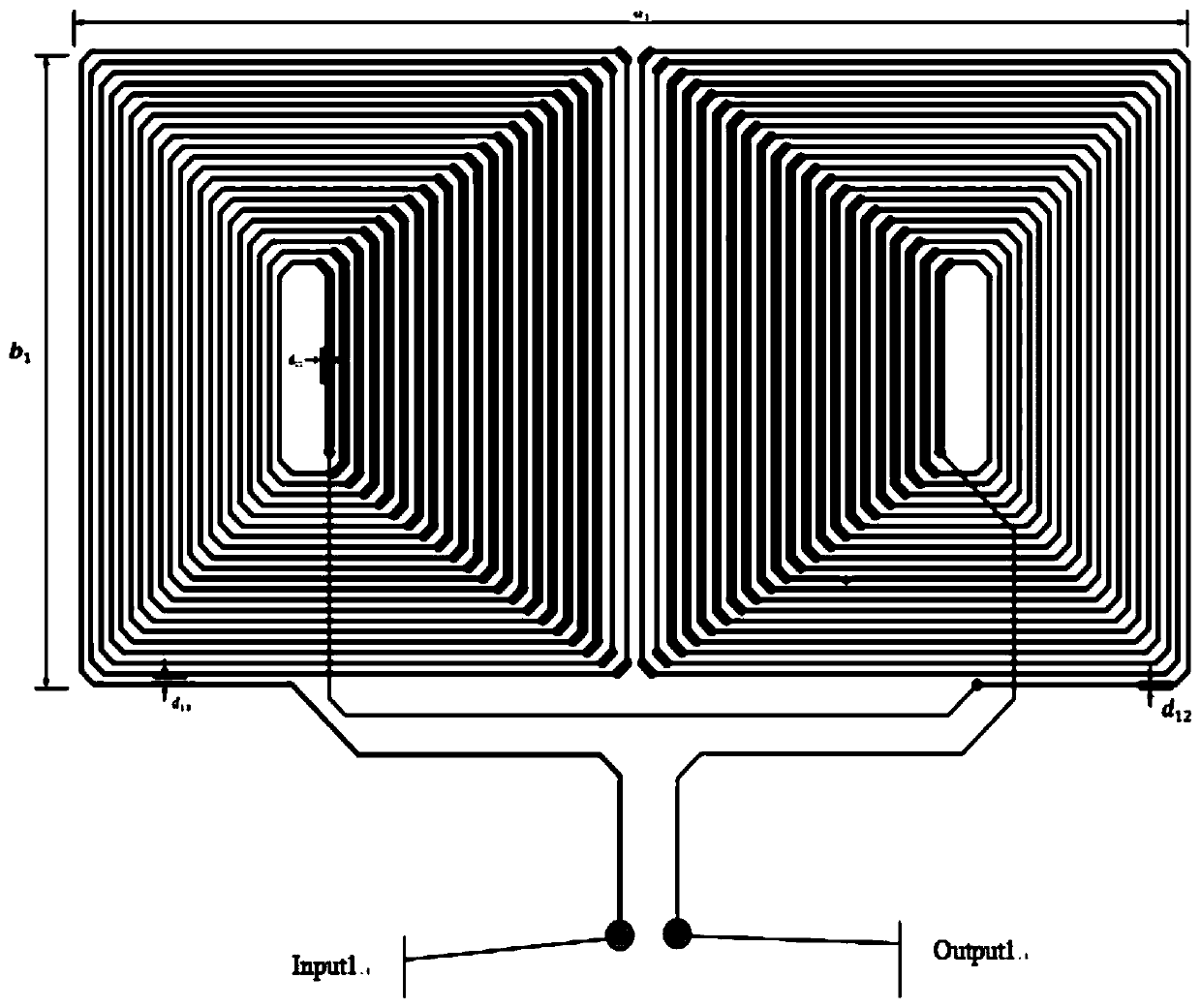

[0034] Such as figure 2 As shown, the excitation coil is a single-layer PCB rectangular differential coil, which is provided with input and output interfaces input1 and output1 for external excitation signals; the length of the PCB rectangular differential coil is a 1 , with a width of b 1 , the wire diameter of the middle differential area is d 11 , and the diameter of the rest of the wires is d 12 , the line spacing is d 13 , and d 11 > d 12 ;

[0035] In this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com