Electronic device and method of manufacturing the same

An electronic component and a manufacturing method technology, which are applied in the field of electronic components with no-gap through holes and the manufacturing field thereof, can solve the problems of poor step coverage of contact holes, difficulty of no-gap through holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

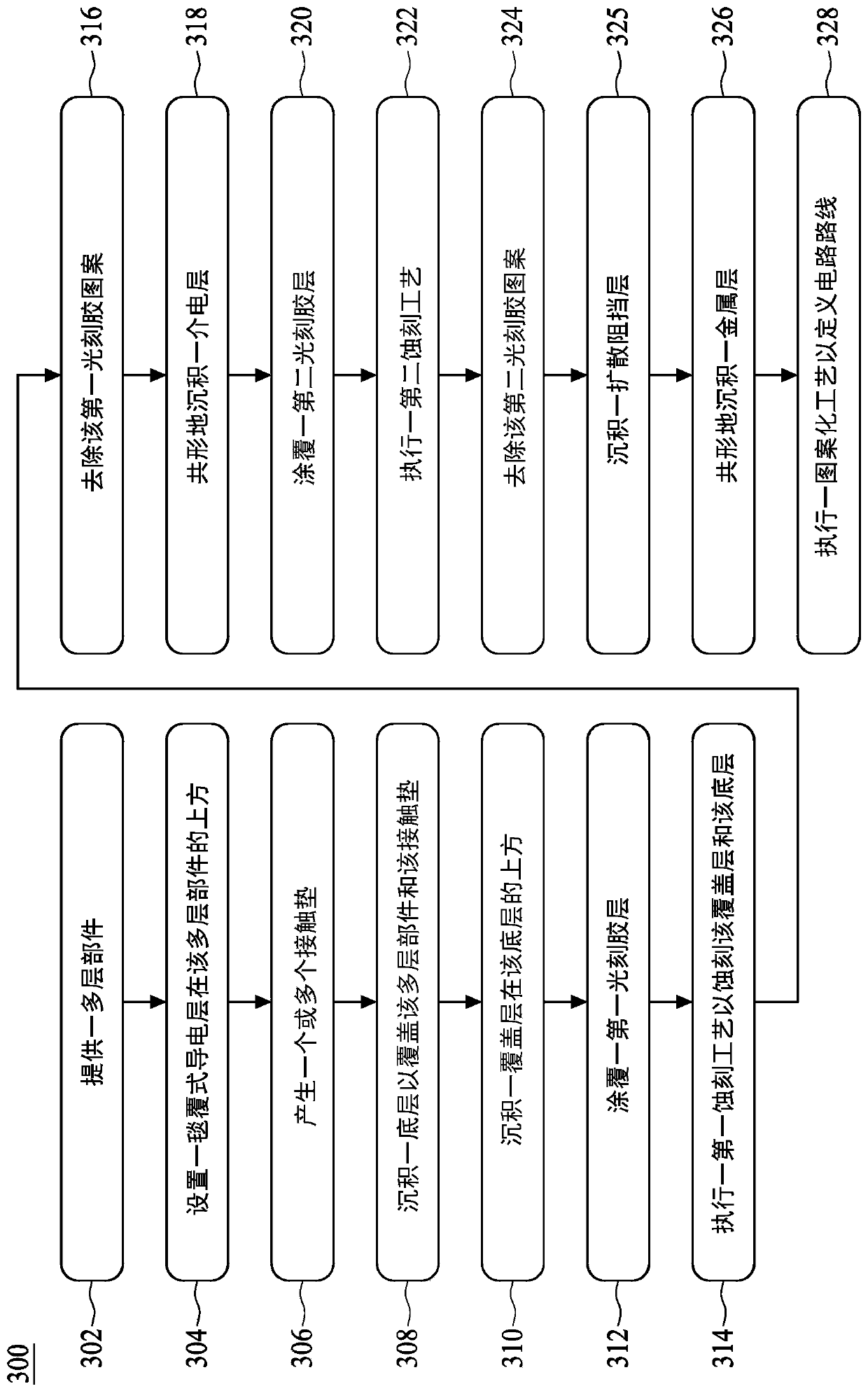

[0099] figure 2 It is a flowchart, and a method 300 of the electronic component 10 or 10a of the present disclosure is illustrated. Figure 3 to 20 It is a variety of manufacturing stages of the preparation method 300 of the electronic component 10 or 10a of some embodiments disclosed. Figure 3 to 20 The various stages figure 2 A schematic description of the manufacturing process. In the following description, Figure 3 to 20 The manufacturing step shown in the presentation corresponds to reference figure 2 Manufacturing steps in.

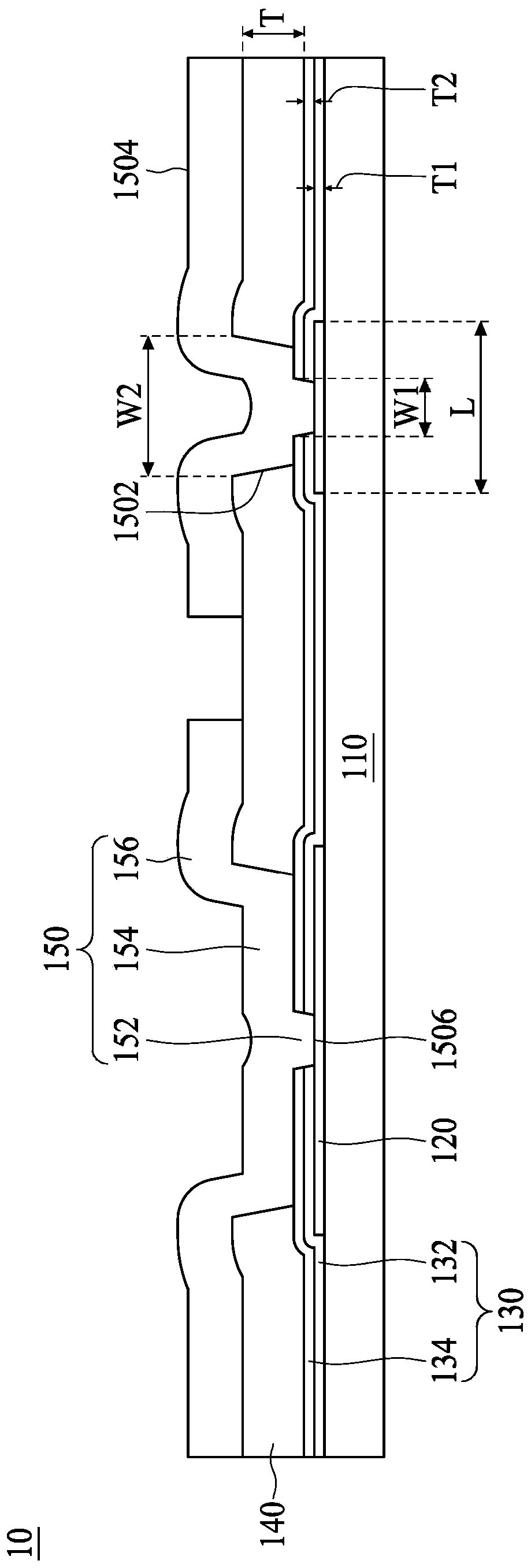

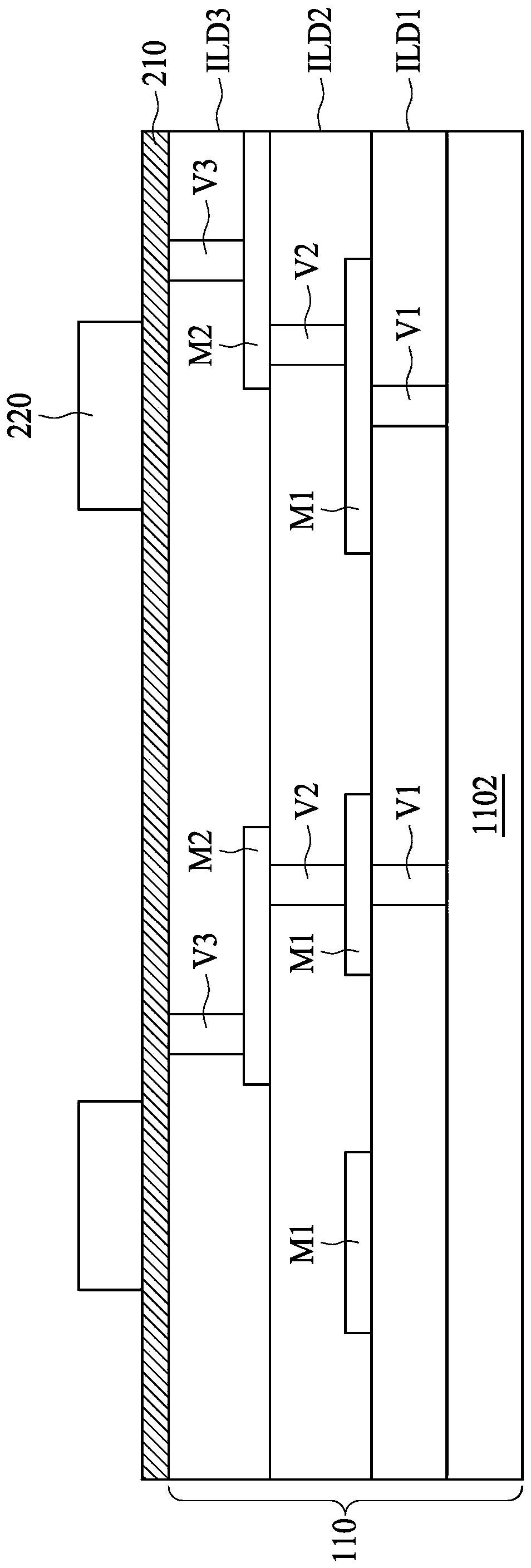

[0100] Refer image 3 ,according to figure 2 In step 302, a multilayer member 110 is provided. In some embodiments, the multilayer component 110 can include a primary component 1102, mainly composed of 1102 including one or more feature elements, such as transistors, resistors, capacitors, and diodes. In some embodiments, the multilayer member 110 may further include an interconnect structure including alternating stacks of wiring layers M1, M2, and thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com