Method for producing thin film

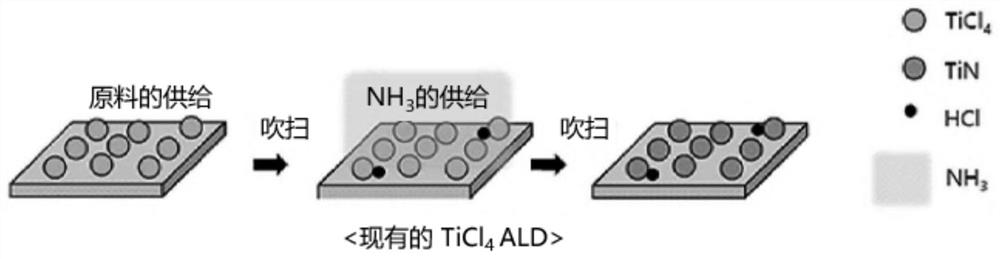

A thin-film manufacturing method and thin-film technology, which are applied in semiconductor/solid-state device manufacturing, coating, gaseous chemical plating, etc., can solve problems such as corrosion of aluminum and other metals, film quality deterioration, and step coverage problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

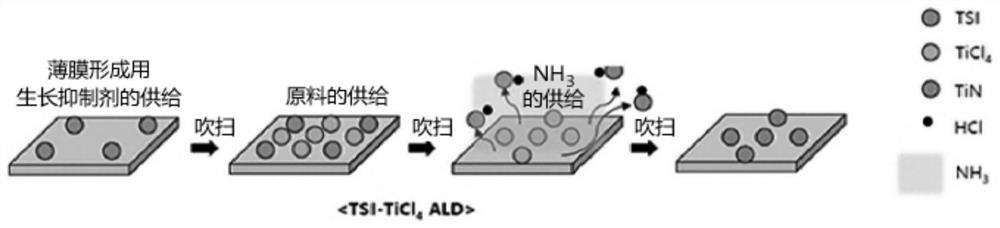

Method used

Image

Examples

Embodiment 1 to 7

[0102] Prepare the growth inhibitor for thin film formation and TiCl as Ti-based thin film precursor described in Table 1 below. 4 . The prepared growth inhibitor for thin film formation was filled in a tank, and supplied to a vaporizer heated to 150° C. at a flow rate of 0.05 g / min by LMFC (Liquid Mass Flow Controller) at room temperature. After 3 seconds of injecting the growth inhibitor for thin film formation vaporized into the vapor phase in the evaporator into the deposition chamber loaded with the substrate, argon gas was supplied at 3000 sccm for 6 seconds and purged with argon gas. At this time, the pressure in the reaction chamber was controlled to 1.3 Torr. Then, the prepared TiCl 4 It was put into another tank, and was supplied to another evaporator heated to 150° C. at a flow rate of 0.05 g / min using LMFC (Liquid Mass Flow Controller) at normal temperature. TiCl vaporized into the vapor phase in the evaporator 4 After being put into the deposition chamber for ...

experiment example

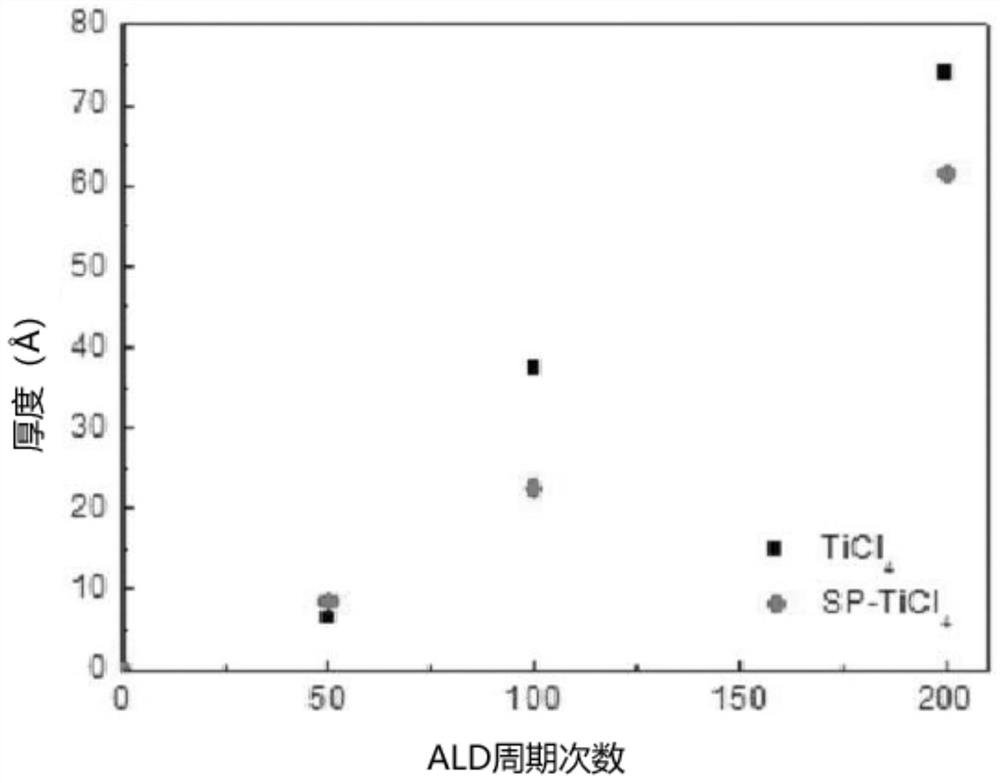

[0110] 1) Deposition evaluation

[0111] Referring to Table 2 below, Example 1 in which 2-chloro-2-methylbutane was used as a growth inhibitor for film formation was compared with Comparative Example 1 in which it was not included. As a result, the deposition rate is / Cycle, compared with Comparative Example 1, the deposition rate was reduced by more than 55.5%. It could be confirmed that the remaining Examples 2 to 7 also had deposition rates of similar values to Example 1. In addition, it was confirmed that Comparative Examples 2 and 3, which did not use the growth inhibitor for thin film formation of the present invention but used pentane or cyclopentane, had the same deposition rate as Comparative Example 1. At this time, a decrease in the deposition rate indicates a change in the CVD deposition characteristics to the ALD deposition characteristics, and thus can be used as an indicator of improvement in the step coverage characteristics.

[0112] Table 2

[0113] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com