Method for making wear-resistant dielectric layer

A manufacturing method and dielectric layer technology, applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., to achieve the effect of improving yield and reliability, and improving step coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

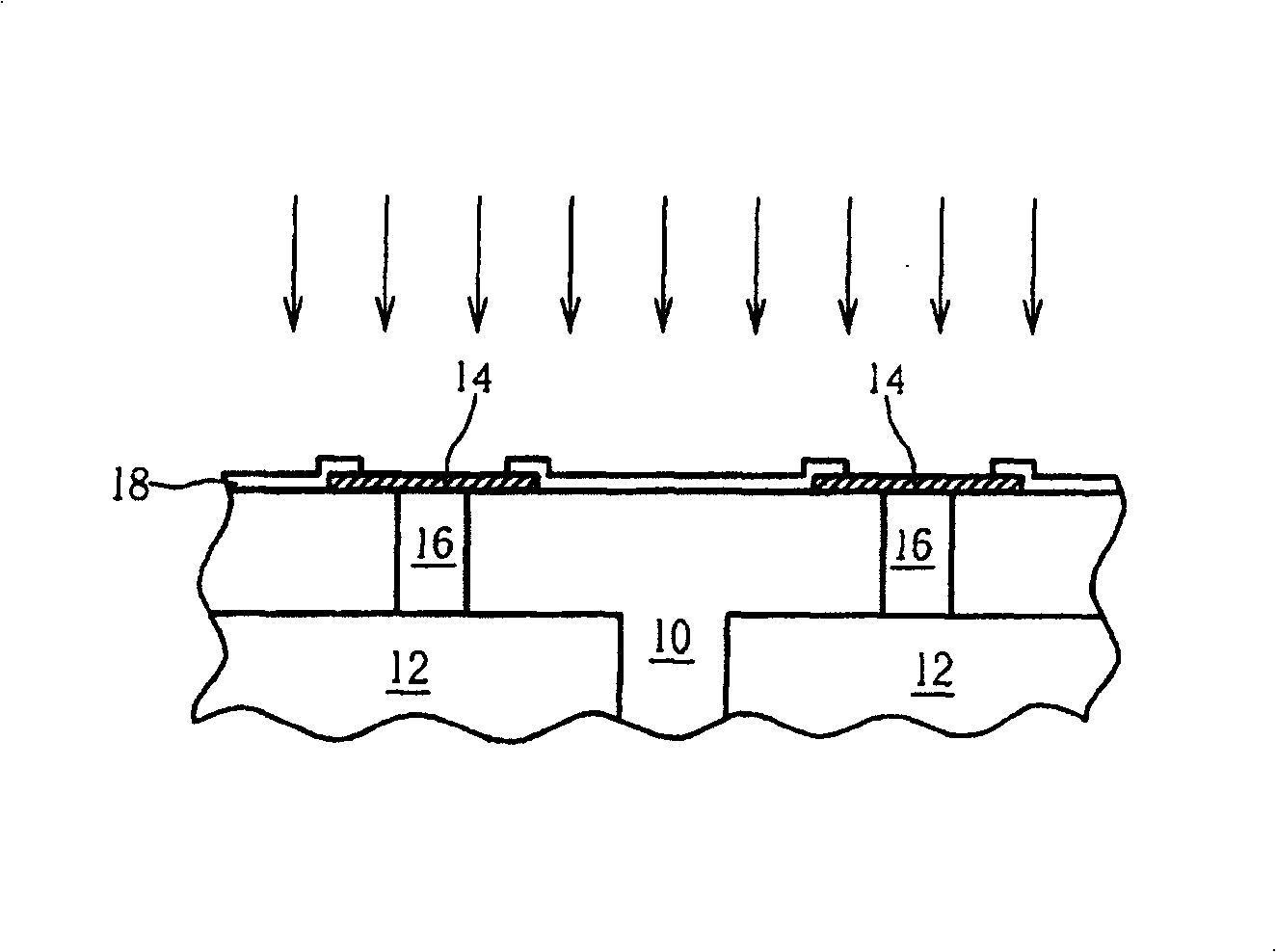

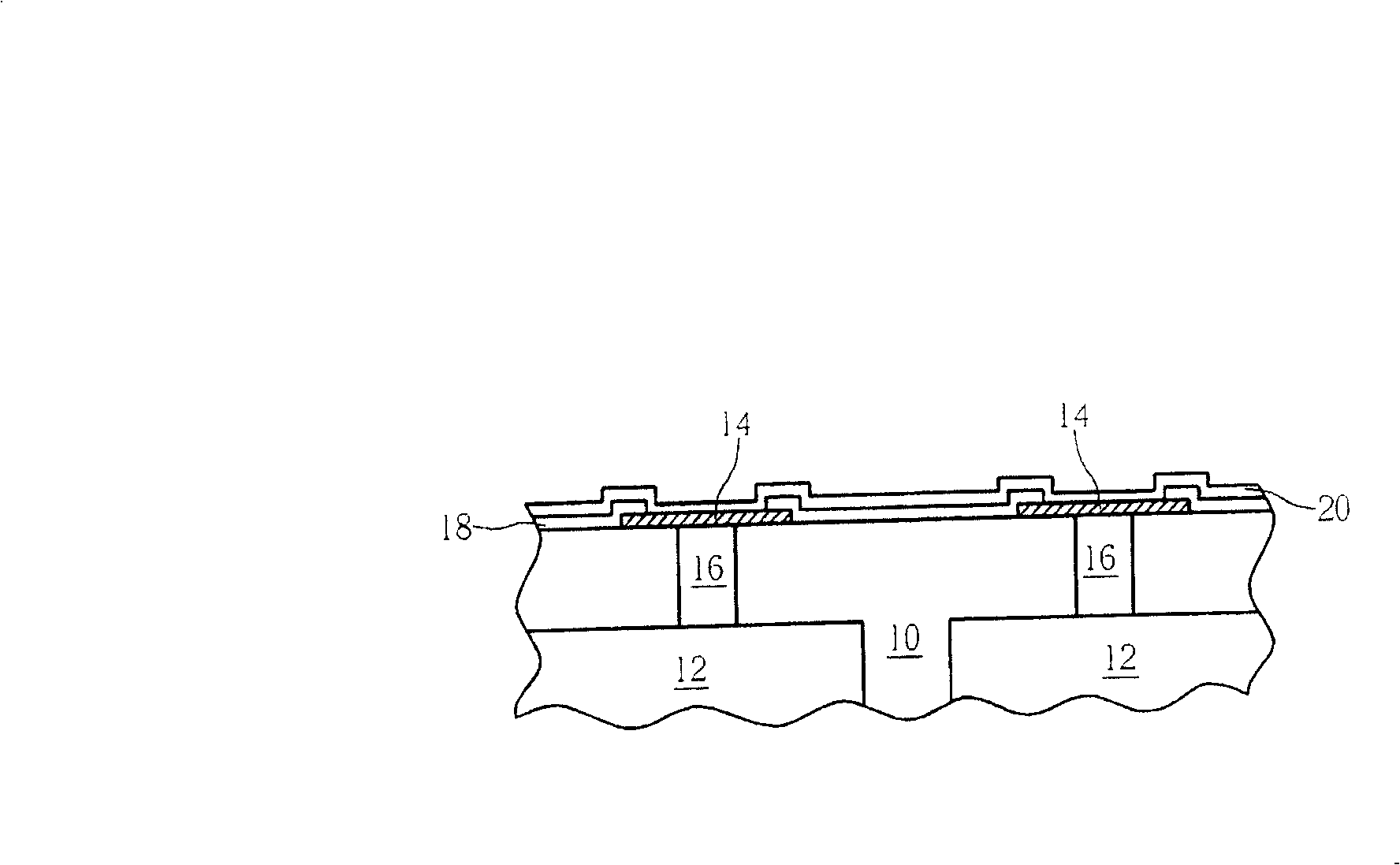

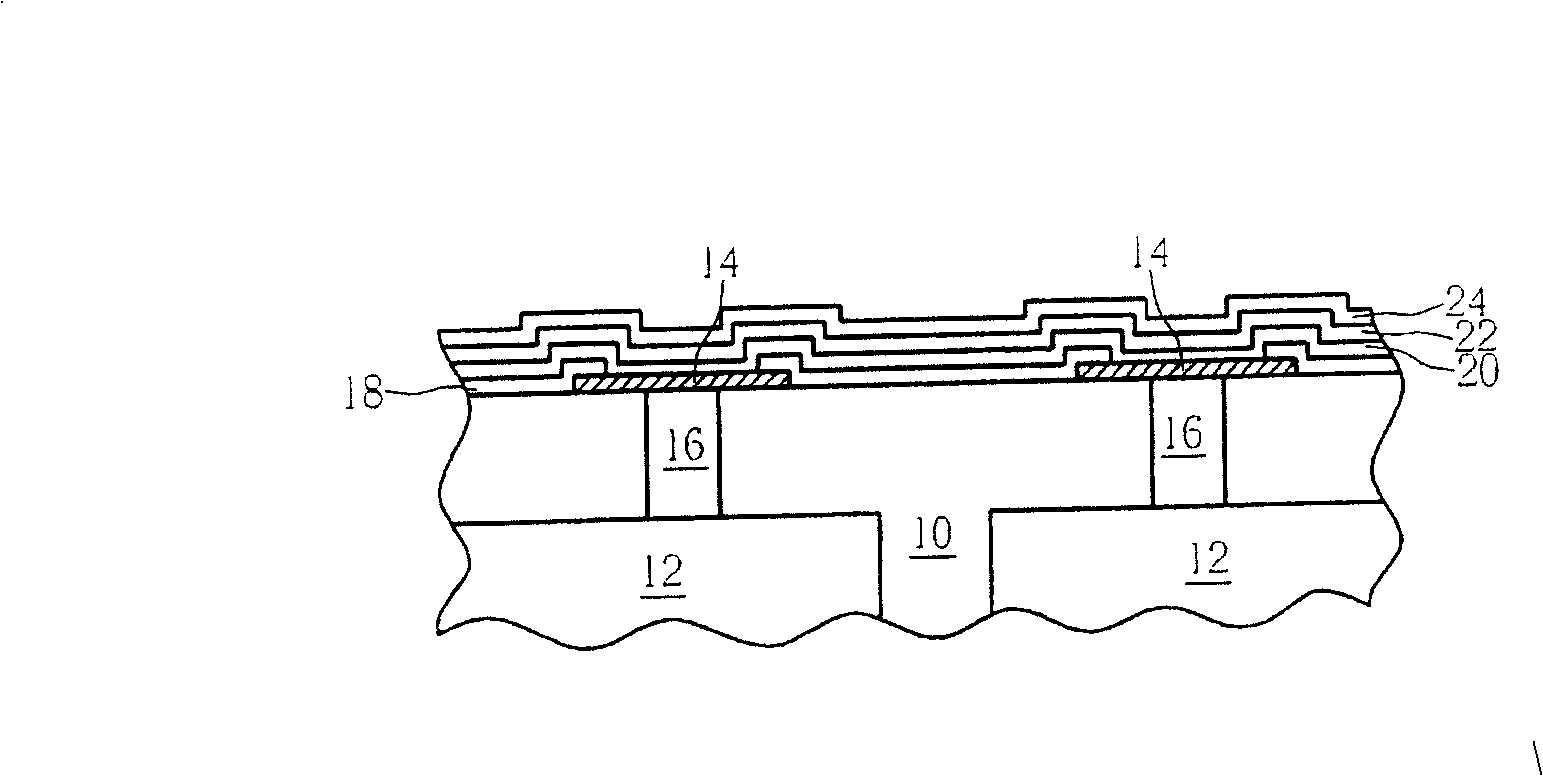

[0019] Please refer to Figure 1 to Figure 8 . Figure 1 to Figure 8 It is a schematic diagram of a method for fabricating a wear-resistant dielectric layer in a preferred embodiment of the present invention. Such as figure 1 As shown, a substrate 10 is first provided, and the substrate 10 includes a plurality of elements 12, and a plurality of connection pads 14 are arranged on the surface of the substrate 10, and are electrically connected to the elements 12 by a plug 16, wherein the elements 12 are semiconductor elements or microelectromechanical components, etc. In addition, the surface of the substrate 10 further includes a surface dielectric layer 18 . Then carry out a surface treatment process to the surface dielectric layer 18, to remove the organic pollutants and particles attached to the surface dielectric layer 18, and increase the distance between the surface dielectric layer 18 and the subsequently formed dielectric layer (not shown). Adhesion between. In this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com