Multifunctional catalyst for denitration, dust removal and dioxin removal as well as preparation method and application thereof

A technology for removing dioxins, denitration and dust removal, applied in chemical instruments and methods, chemical elements of heterogeneous catalysts, physical/chemical process catalysts, etc., can solve the problems of large equipment footprint, practicability and applicability of flue gas treatment Problems such as limiting and increasing the amount of catalyst wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

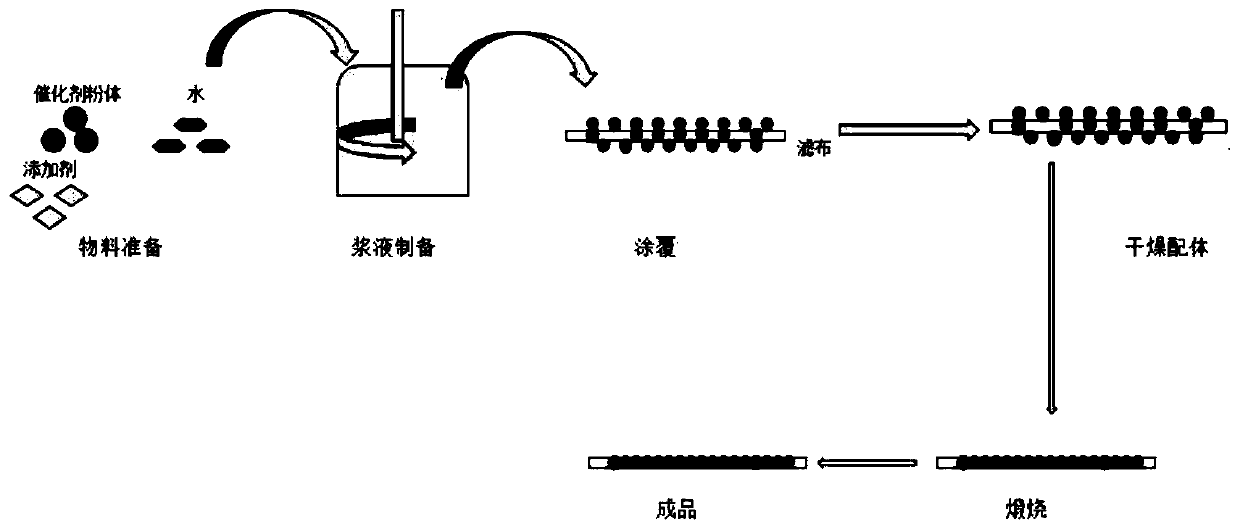

[0039] The present invention also provides a preparation method of the multifunctional catalyst described in the above technical scheme, comprising the following steps (such as figure 1 shown):

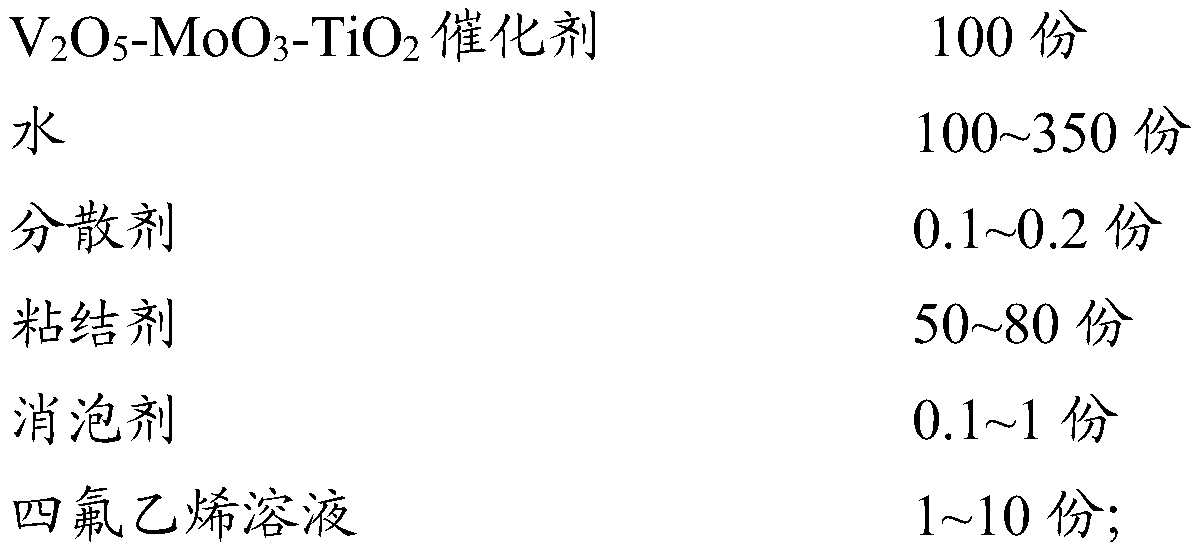

[0040] will V 2 o 5 -MoO 3 -TiO 2 The catalyst, water, dispersant, binder, defoamer and tetrafluoroethylene solution are mixed to obtain a slurry containing the catalyst;

[0041] The slurry is coated on a filter cloth and calcined to obtain the multifunctional catalyst.

[0042] The present invention will V 2 o 5 -MoO 3 -TiO 2The catalyst, water, dispersant, binding agent, defoamer and tetrafluoroethylene solution are mixed to obtain a slurry containing the catalyst; in the present invention, the mixing is preferably carried out under stirring conditions; the stirring time is preferably It is 10-20 h, more preferably 12-18 h, and most preferably 14-16 h; the present invention does not have any special limitation on the stirring rate, and it can be carried out at a rate well ...

Embodiment 1

[0048] 100g V 2 o 5 -MoO 3 -TiO 2 Catalyst (V 2 o 5 、MoO 3 and TiO 2 The mass ratio is 4.5:6:89.5), 100g of water, 0.1g of polymaleic acid and 50g of silica sol were mixed for 12h under stirring conditions, and then 1g of polyether modified polysiloxane and 5g of tetrafluoroethylene solution were added, obtaining a slurry comprising the catalyst;

[0049] 9g of the slurry containing the catalyst is coated on a 20g filter cloth, dried at 80°C for 12h, and then calcined (200°C, 3h) to obtain 24.5g of the multifunctional catalyst, which is denoted as catalyst one (increase of filter cloth) The weight ratio is 22.5%).

Embodiment 2

[0051] 100g V 2 o 5 -MoO 3 -TiO 2 Catalyst (V 2 o 5 、MoO 3 and TiO 2 The mass ratio is 4.5:6:89.5), 150g water, 0.1g polymaleic acid and 50g silica sol were mixed under stirring conditions for 12h, then added 1g polyether modified polysiloxane and 5g tetrafluoroethylene solution, obtaining a slurry comprising the catalyst;

[0052] 6.4g of the slurry containing the catalyst is coated on a 20g filter cloth, dried at 80°C for 12h, and then calcined (200°C, 3h) to obtain 23.2g of the multifunctional catalyst, which is denoted as catalyst two (filter cloth Weight gain was 16%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com