Oil storage tank mechanical cleaning and sump oil purifying system and method

A mechanical cleaning and purification system technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as the flow mismatch between the cleaning system and the purification system, improve disposal efficiency, improve purification efficiency, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

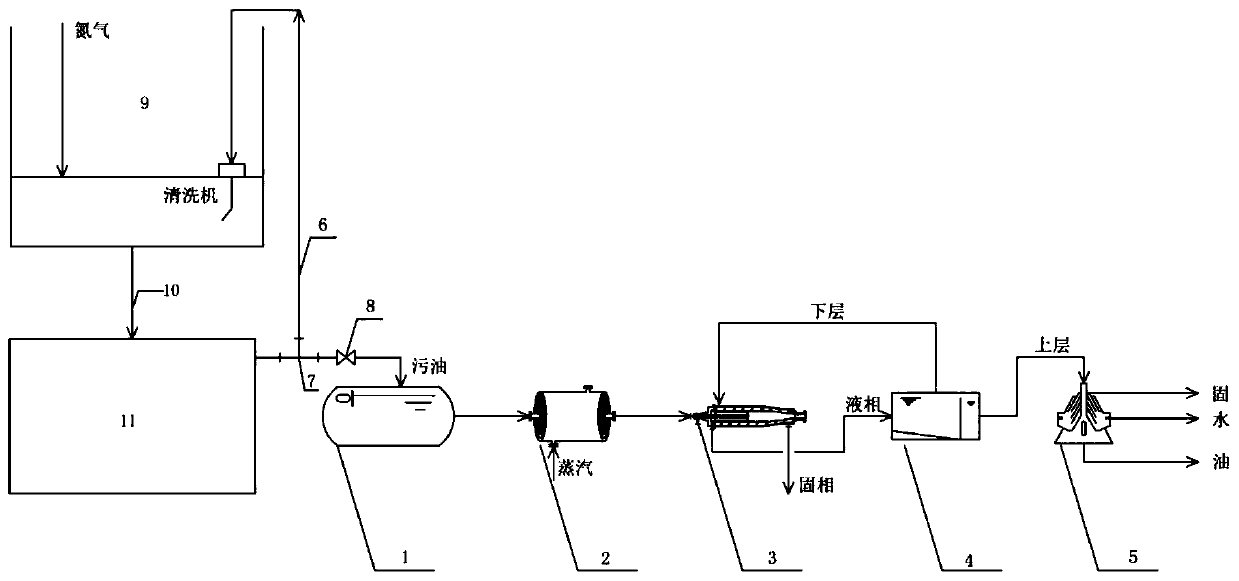

[0024] like figure 1 As shown, an oil storage tank mechanical cleaning dirty oil purification system includes a cleaning system and a purification system. The cleaning system includes an oil storage tank 9 and a mechanical cleaning device 11. The purification system includes a buffer unit 1 and a heat exchange unit 2. , a two-phase horizontal centrifugal unit 3, a settling separation unit 4 and a three-phase disc centrifugal unit 5, the oil storage tank 9 is connected to the inlet of the mechanical cleaning device 11 through a recovery pipeline 10, and the mechanical cleaning device 11 The outlet is divided into two paths through the tee 7, and one path is connected to the oil storage tank 9 through the cleaning pipeline 6. Further preferably, a cleaning machine is provided in the oil storage tank 9, and the mechanical cleaning device 11 includes a vacuum suction device , pressure pumping equipment and heat exchangers. The vacuum suction equipment sucks the dirty oil from the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap