Machining method of thin-wall abnormally-shaped metal casting

A technology for special-shaped metals and castings, which is applied in the field of castings processing, and can solve problems such as out-of-tolerance contours and uneven wall thicknesses of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

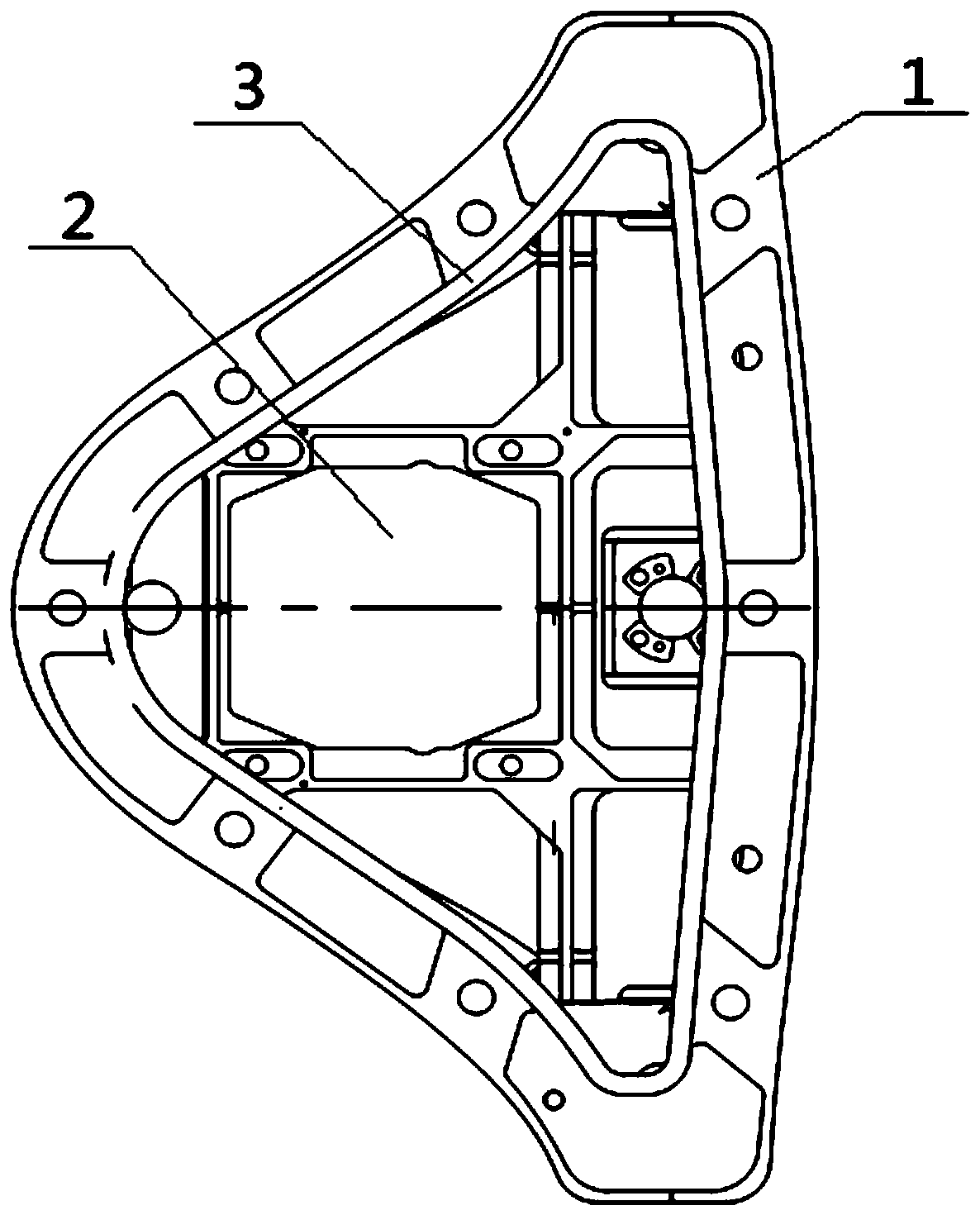

[0141] like figure 2 As shown, it is a structural schematic diagram of the end view of an aluminum alloy casting with a cross-sectional dimension of 1170×821 and an axial dimension of 1200 mm, which is integrally cast and processed from an aluminum alloy. The figure includes the end 1 of the aluminum alloy casting, the inner cavity 2 of the aluminum alloy casting and the aluminum alloy casting shell 3, wherein the end 1 of the aluminum alloy casting includes a half end face, an end face contact hole, a high-precision hole system and an end face.

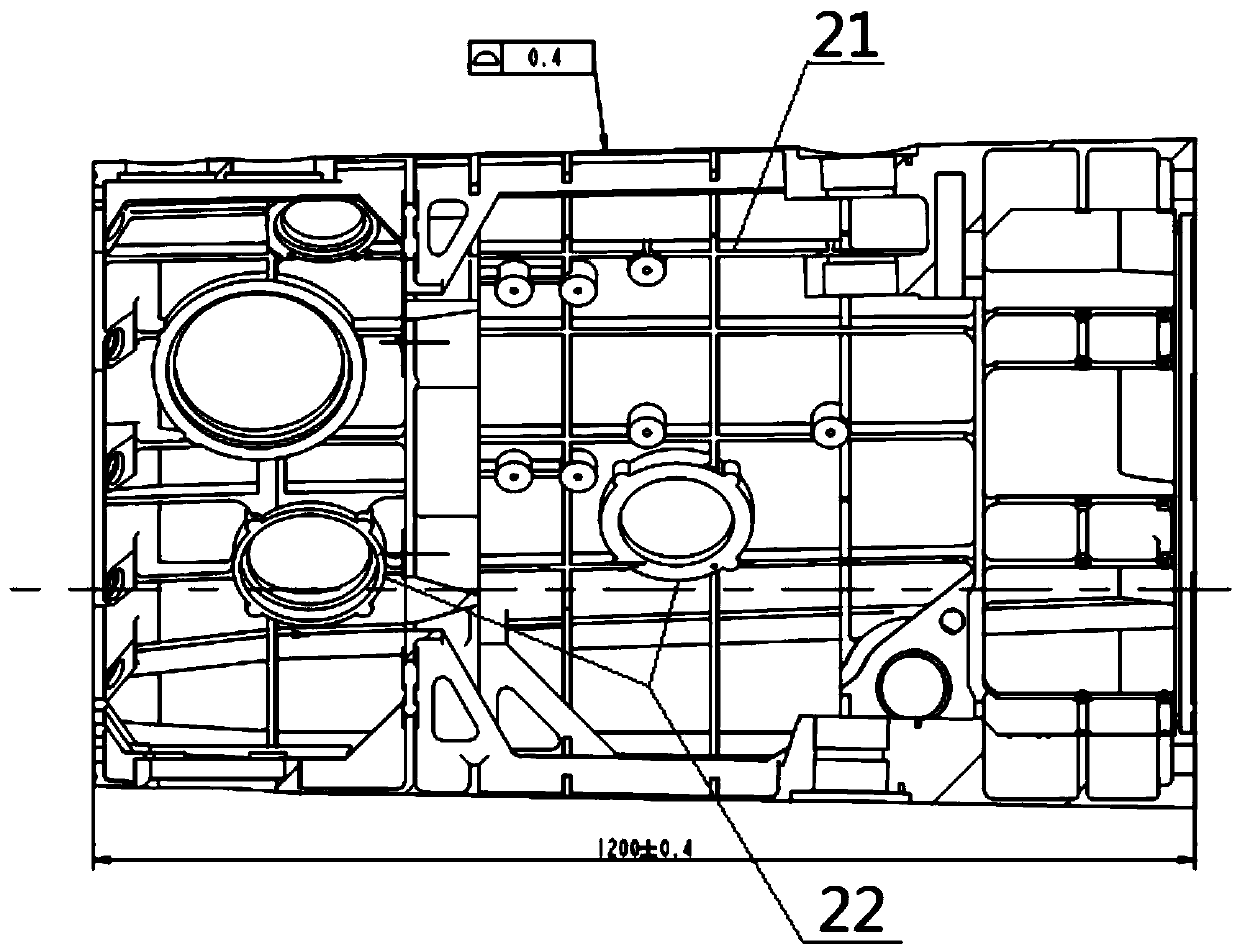

[0142] like image 3 shown, for figure 2 Schematic diagram of the partial structure of the inner cavity, the figure includes: the inner cavity profile 21 of the aluminum alloy casting and the inner cavity mounting part 22 of the aluminum alloy casting, and the inner cavity profile 21 of the aluminum alloy casting has multiple inner meshes of different sizes. The lattice surface has a thickness of 2.5mm to 3.5mm.

[0143] specifi...

experiment example 2

[0187] like figure 2 As shown, it is a schematic view of the structure of an aluminum alloy casting with a cross-sectional dimension of 1170×821 and an axial dimension of 1200mm, which is integrally cast and processed from aluminum alloy. The figure includes the end 1 of the aluminum alloy casting, the inner cavity 2 of the aluminum alloy casting and the shell 3 of the aluminum alloy casting, wherein the end 1 of the aluminum alloy casting includes a half end face, an end face connecting hole, a high-precision hole system and an end face.

[0188] like image 3 shown, for figure 2 A schematic diagram of the local structure of the inner cavity of the aluminum alloy casting, which includes: the inner cavity surface 21 of the aluminum alloy casting and the inner cavity mounting part 22 of the aluminum alloy casting, and the inner cavity surface 21 of the aluminum alloy casting has multiple inner nets of different sizes Grid curved surface, its thickness is 2.5mm ~ 3.5mm.

[...

experiment example 3

[0233] like figure 2 As shown, it is a schematic view of the structure of an aluminum alloy casting with a cross-sectional dimension of 1170×821 and an axial dimension of 1200mm, which is integrally cast and processed from aluminum alloy. The figure includes the end 1 of the aluminum alloy casting, the inner cavity 2 of the aluminum alloy casting and the shell 3 of the aluminum alloy casting, wherein the end 1 of the aluminum alloy casting includes a half end face, an end face connecting hole, a high-precision hole system and an end face.

[0234] like image 3 shown, for figure 2 A schematic diagram of the local structure of the inner cavity of the aluminum alloy casting, which includes: the inner cavity surface 21 of the aluminum alloy casting and the inner cavity mounting part 22 of the aluminum alloy casting, and the inner cavity surface 21 of the aluminum alloy casting has multiple inner nets of different sizes Grid curved surface, its thickness is 2.5mm ~ 3.5mm.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com