Ceramic sheet aluminum honeycomb composite board system and construction method thereof

A ceramic sheet and composite board technology, applied in the direction of floor, covering/lining, construction, etc., can solve the problems of difficult cleaning of pollutants, easy fading and discoloration, water absorption, falling off, etc., to save adhesive materials, prevent high-altitude falling off, The effect of absorbing construction errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0061] The ceramic sheet aluminum honeycomb composite panel system of this embodiment is mainly used for new construction, reconstruction and expansion of civil buildings and energy-saving renovation of exterior walls of existing buildings with an elevation not exceeding 100m.

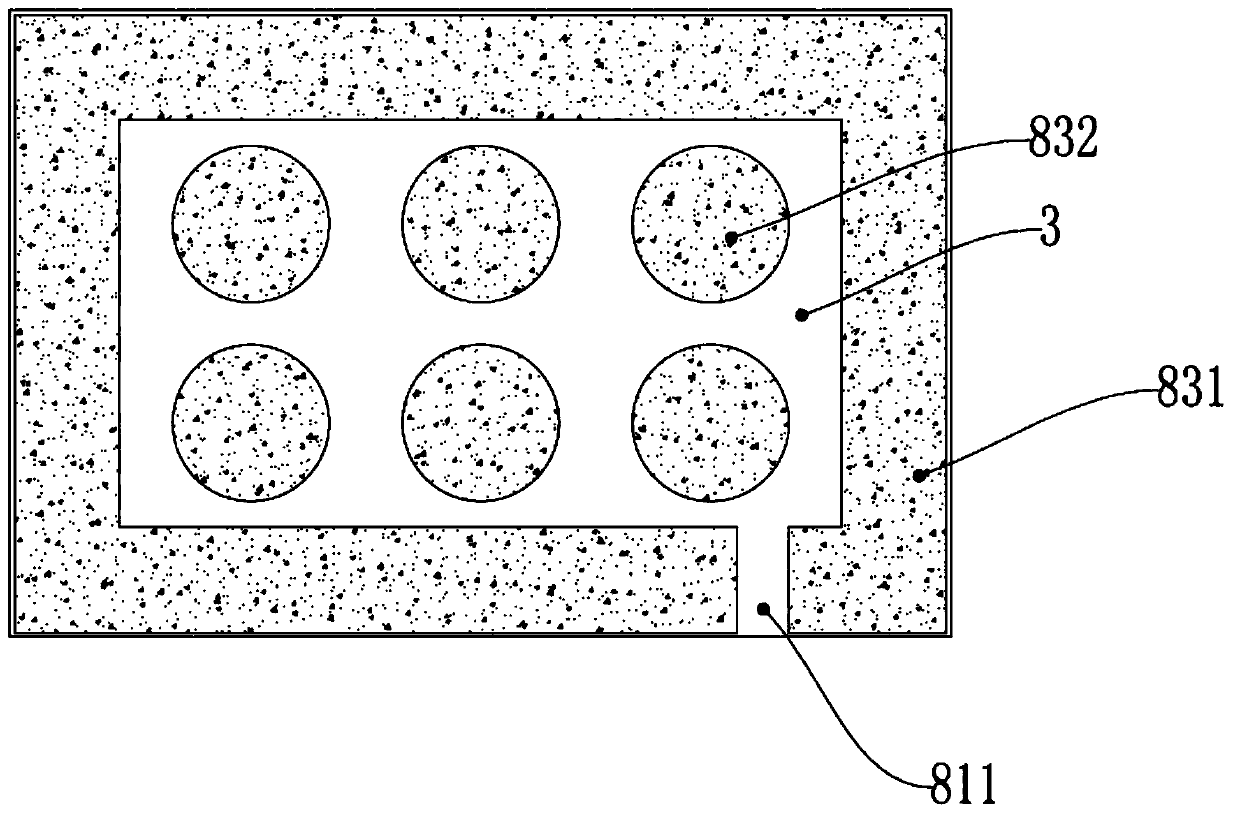

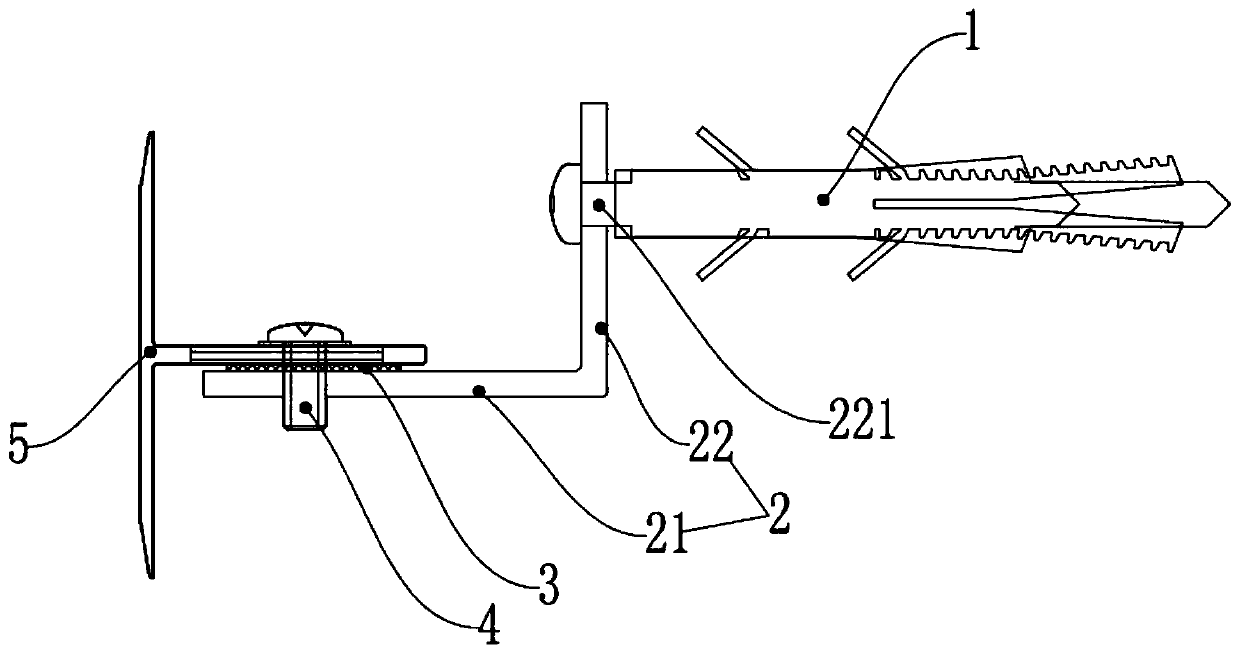

[0062] Such as Figure 1-7 As shown, a ceramic sheet aluminum honeycomb composite panel system includes a composite panel 81, an anchor assembly 82 and an adhesive layer 83;

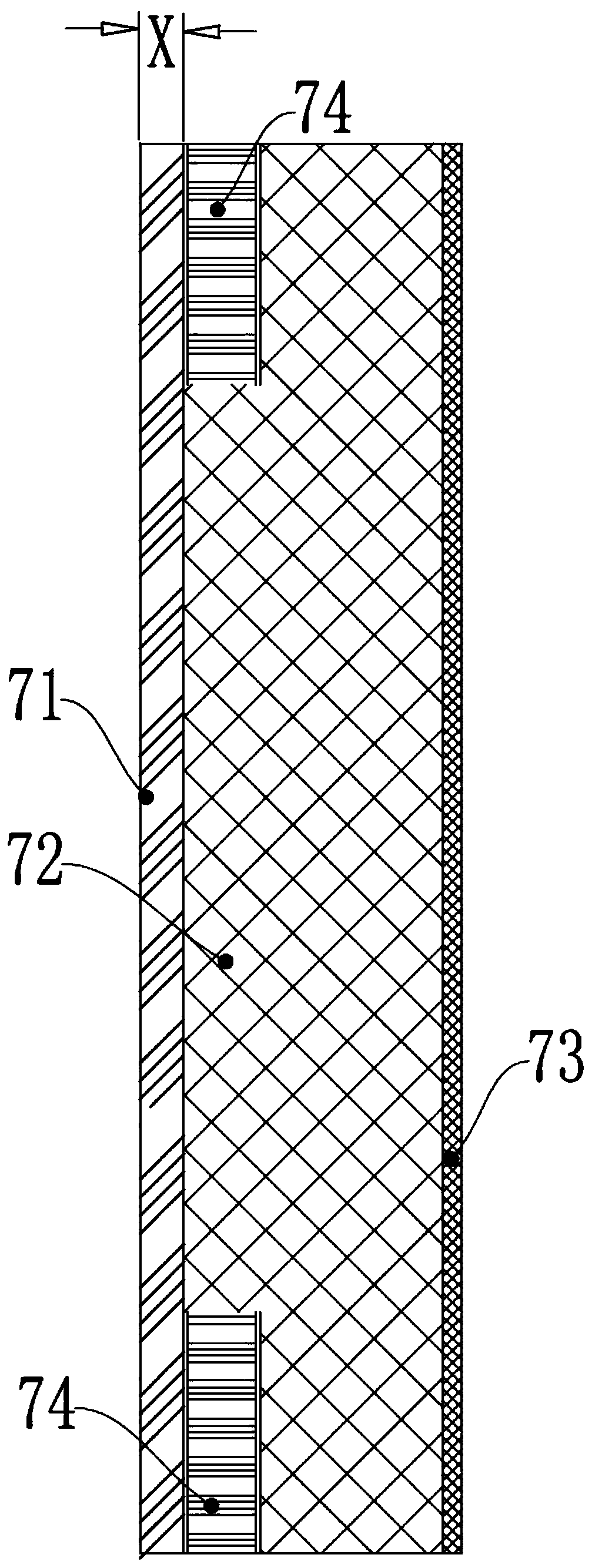

[0063]Including ceramic sheet 71, insulation layer 72, backing layer 73 and aluminum honeycomb panel 74;

[0064] The right side of the ceramic thin plate 71 is bonded to the left side of the thermal insulation layer 72, and the right side of the thermal insulation layer 72 is bonded to the left side of the backing layer 73;

[0065] The aluminum hon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap