Demisting device for medical protective glasses and medical protective glasses

A technology of a defogging device and protective goggles, applied in the field of medical machinery, can solve the problems of inability to use medical goggles after installation, no defogging function, heavy resistance wire, etc., and achieves good defogging effect and defogging. The effect of high efficiency and long heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

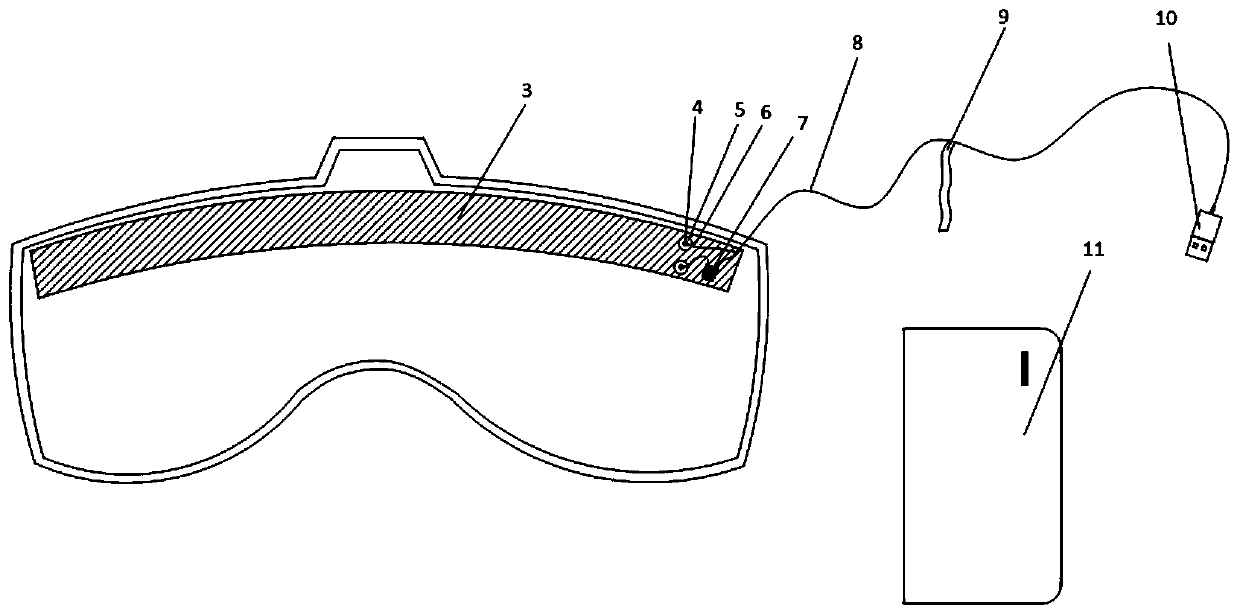

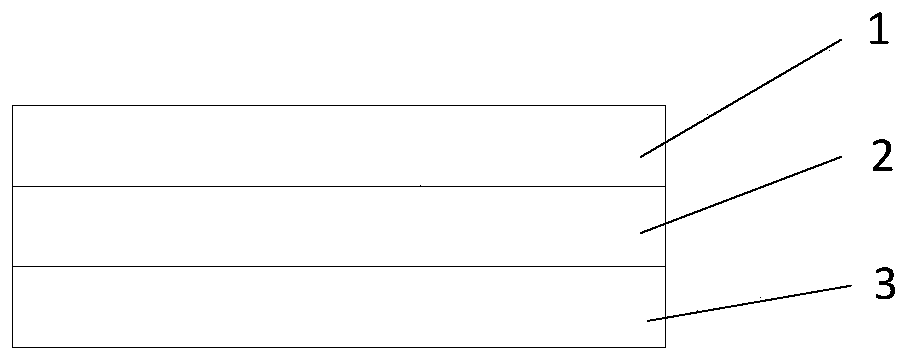

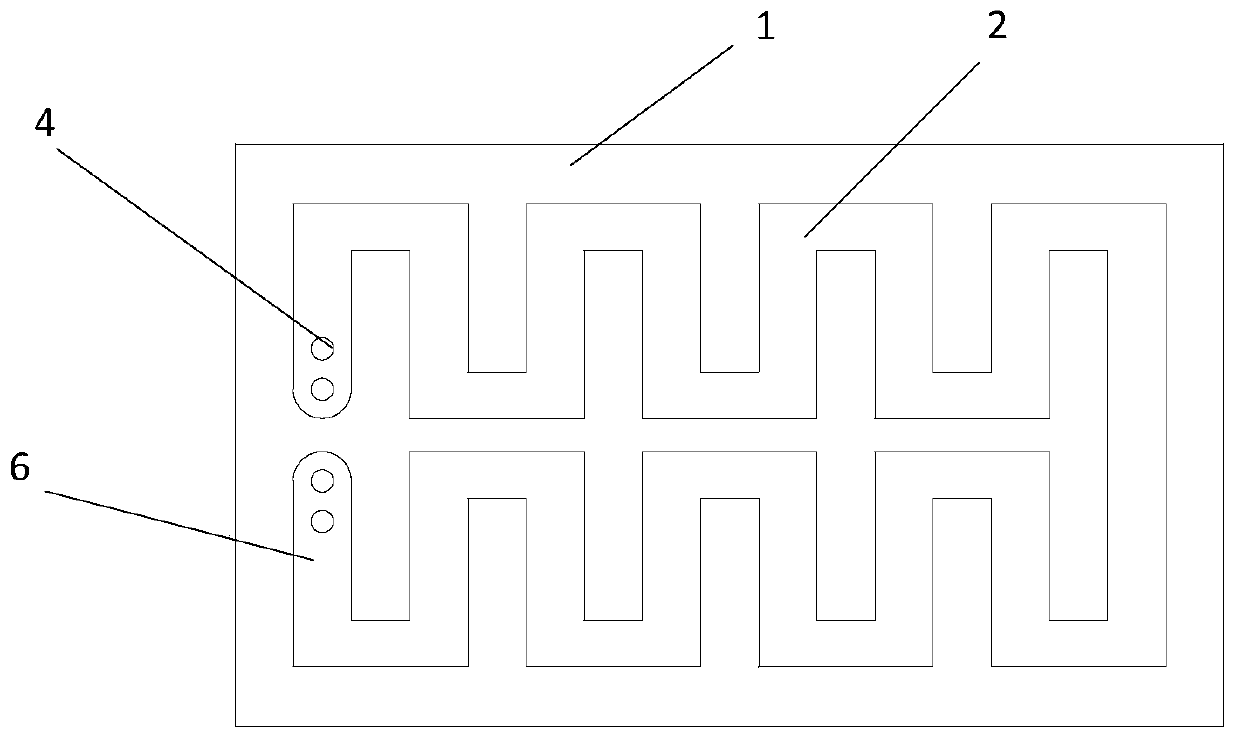

[0027] Such as figure 1 As shown, the defogging device for medical protective glasses of the present invention includes a base film 1, a graphene transparent conductive film 2, a cover film 3, a magnetic suction hole 4, a waterproof ring 5, a free end 6, a high temperature protection module 7, and a power connection wire 8 , Fastener 9, USB power interface 10, mobile power supply 11.

[0028] The specific structure is as follows:

[0029] The base film 1 is pasted with a graphene transparent conductive film 2, a free end 6 is arranged on the graphene transparent conductive film 2, a magnetic suction hole 4 is arranged on the free end 6, and a waterproof hole 4 is welded on the magnetic suction hole 4. Circle 5, as an electrode. The graphene transparent conductive film 2 has a cover film 3 on it. The high temperature protection module 7 is connected to one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com