Porosity test block screening method, device and equipment and storage medium

A screening method and porosity technology, applied in image data processing, instruments, calculations, etc., can solve problems such as large error in results, difficult implementation, and large volume, and achieve the effect of reducing workload and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

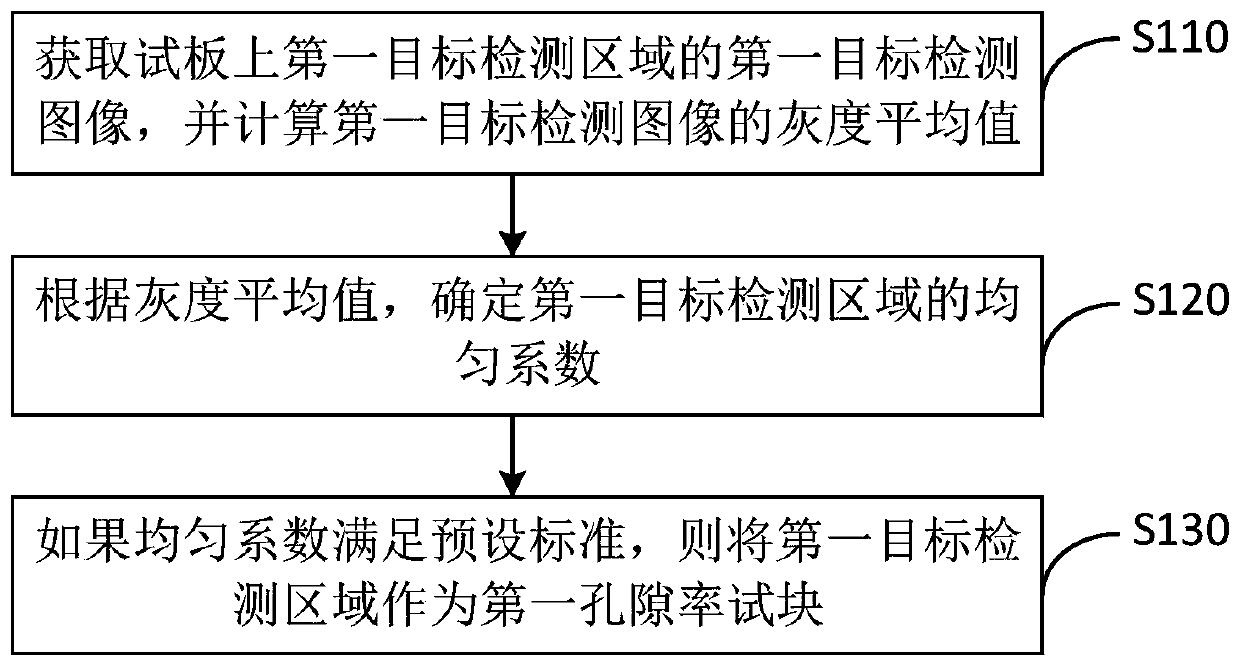

[0027] figure 1 It is a flowchart of a porosity test block screening method provided in Embodiment 1 of the present invention. This embodiment is applicable to the situation of screening porosity test blocks on a test plate. To execute, the device may be implemented in software and / or hardware. Specifically include the following steps:

[0028] S110. Acquire a first target detection image of the first target detection area on the test board, and calculate a grayscale average value of the first target detection image.

[0029] Wherein, the test plate refers to the carrier for porosity test block screening. If the porosity test block is directly manufactured according to the process, due to the imperfection of the process principle and theory, the randomness of human operation and other factors during the production process, it is easy to cause the porosity test block to have process defects and not meet the requirements. actual production standards. Therefore, it is necessa...

Embodiment 2

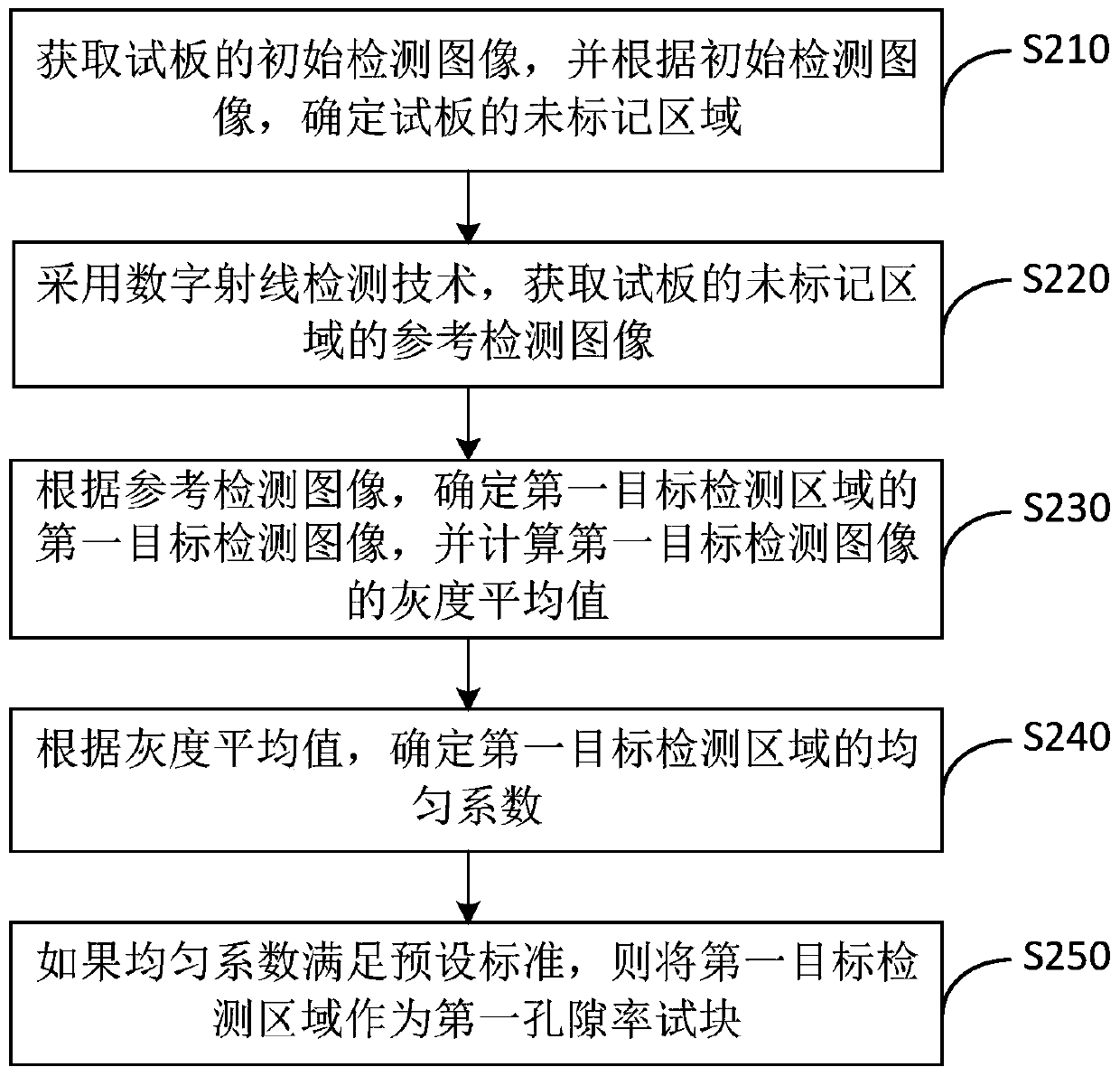

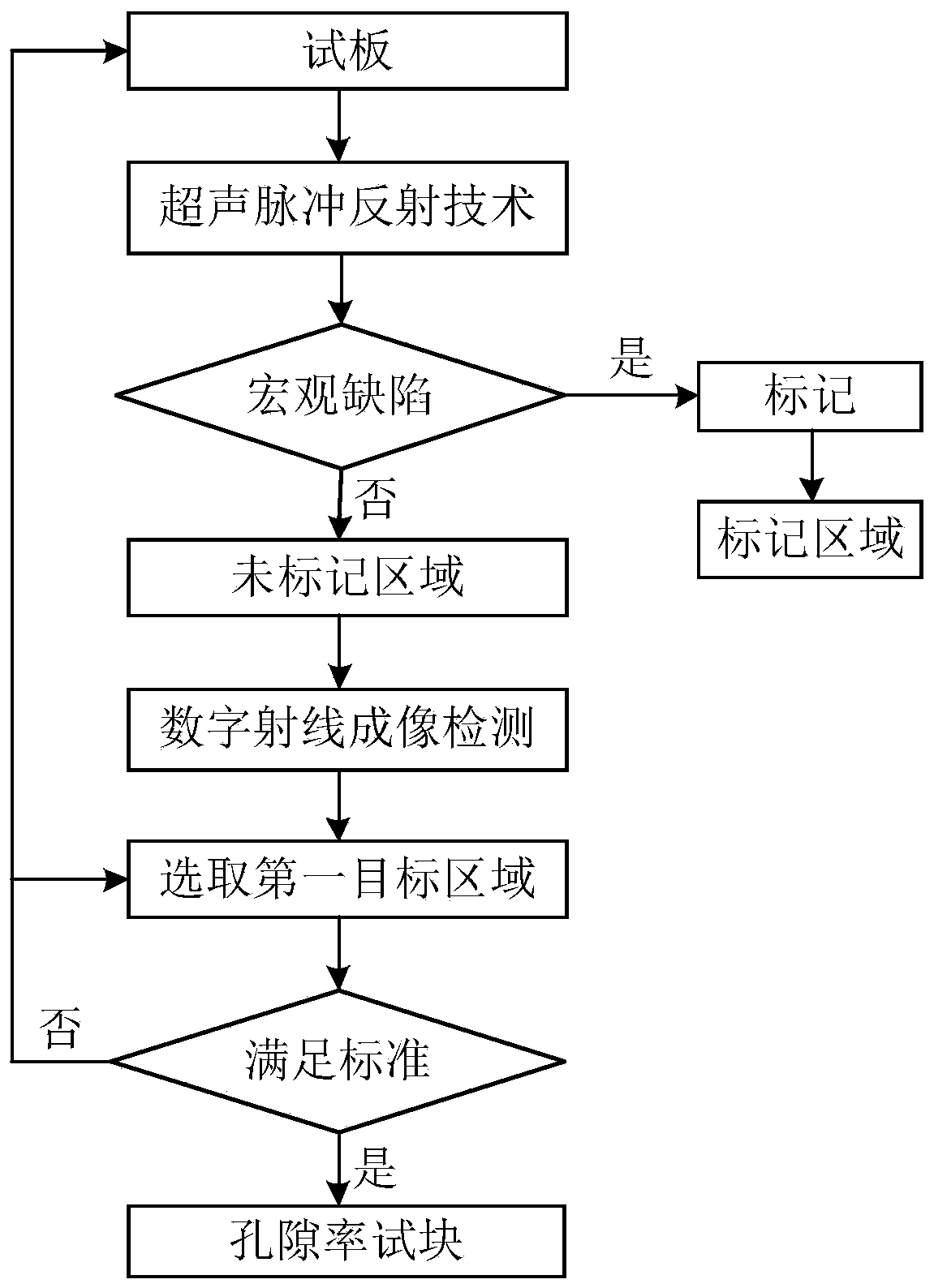

[0054] figure 2 It is a flow chart of a porosity test block screening method provided in Embodiment 2 of the present invention. The technical solution of this embodiment is further refined on the basis of the above embodiments. Optionally, the acquisition of the reference detection image of the test plate by using digital radiography detection technology includes: obtaining an initial detection image of the test plate, and determining the unmarked area of the test plate according to the initial detection image ; Obtain a reference detection image of the unmarked area of the test plate by using digital radiography detection technology.

[0055] The specific implementation steps of the embodiment of the present invention include:

[0056] S210. Acquire an initial detection image of the test board, and determine an unmarked area of the test board according to the initial detection image.

[0057] In one embodiment, optionally, the technical methods for obtaining the init...

Embodiment 3

[0069] Figure 4 It is a schematic diagram of a porosity test block screening device provided in Embodiment 3 of the present invention. This embodiment can be applied to the situation of screening porosity test blocks on the test plate, and the device can be realized by means of software and / or hardware. The screening device for the porosity test block includes: a first target detection image acquisition module 310 , a uniformity coefficient determination module 320 and a first porosity test block determination module 330 .

[0070] Wherein, the first target detection image acquisition module 310 is used to acquire the first target detection image of the first target detection area on the test board, and calculate the gray level average value of the first target detection image;

[0071] A uniformity coefficient determining module 320, configured to determine the uniformity coefficient of the first target detection area according to the average gray value;

[0072] The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com