Elevator machine room temperature intelligent control system and method

An intelligent control system and elevator machine room technology, applied in the field of HVAC, can solve the problems of damage to the main motor of the elevator and the electrical components of the control circuit, uneconomical, waste of electric energy, etc., to avoid equipment or device failure, reduce labor intensity, and save energy. The effect of time management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

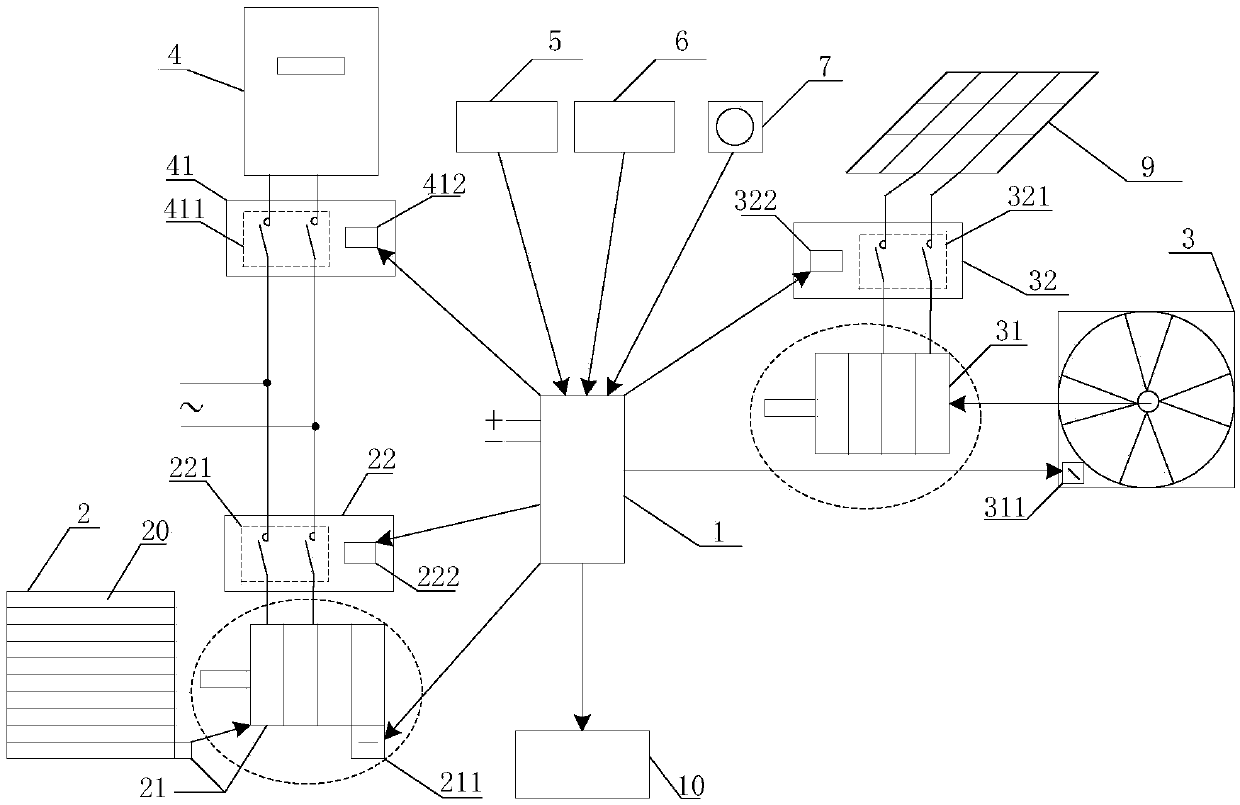

[0059] see figure 1 , is a functional block diagram of an embodiment of an elevator machine room temperature intelligent control system according to the present invention. Specifically, the elevator machine room temperature intelligent control system in this embodiment includes:

[0060] Controller 1, louver 2 with adjustable opening angle, main exhaust fan 3, air conditioner 4, louver motor 21 for adjusting the opening angle of louver 2, normally open louver motor control switch 22, for adjusting the speed gear of main exhaust fan 3 Main exhaust fan motor 31, normally closed main exhaust fan motor control switch 32, normally open air conditioner control switch 41, and the indoor temperature sensor 5 for detecting the indoor temperature in the elevator machine room and the outdoor temperature sensor for detecting the outdoor temperature outside the elevator machine room 6. Wherein, the louver 2 is installed at the bottom of any wall in the elevator machine room, and correspond...

Embodiment 2

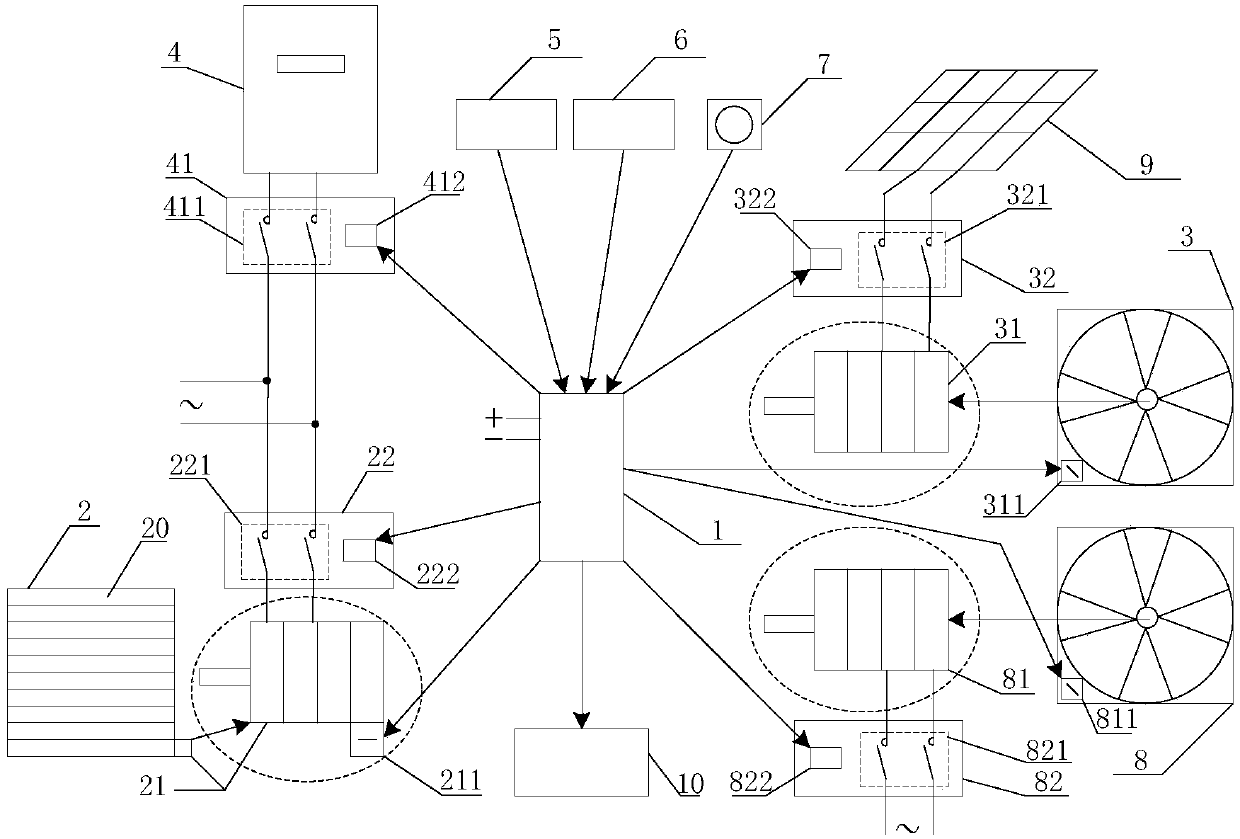

[0069] In order to effectively ensure that the common exhaust fan (ie, the main exhaust fan 3) and its related components can intelligently control the indoor temperature after failure, and also meet the requirements of energy saving, the present invention also provides an elevator machine room temperature intelligent control system, specifically, refer to figure 2 , in this embodiment, in addition to the various components in the above-mentioned first embodiment, it also includes a current sensor 7 for detecting the working current value of the main exhaust fan 3, and a backup exhaust fan 8 installed in parallel next to the main exhaust fan 3 for adjusting the The standby exhaust fan motor 81 with the rotation speed of the standby exhaust fan 8, and the standby exhaust fan motor control switch 82, wherein the standby exhaust fan motor control switch 82 is respectively connected with the controller 1 and the standby exhaust fan motor 81, and the standby exhaust fan motor 81 and...

Embodiment 3

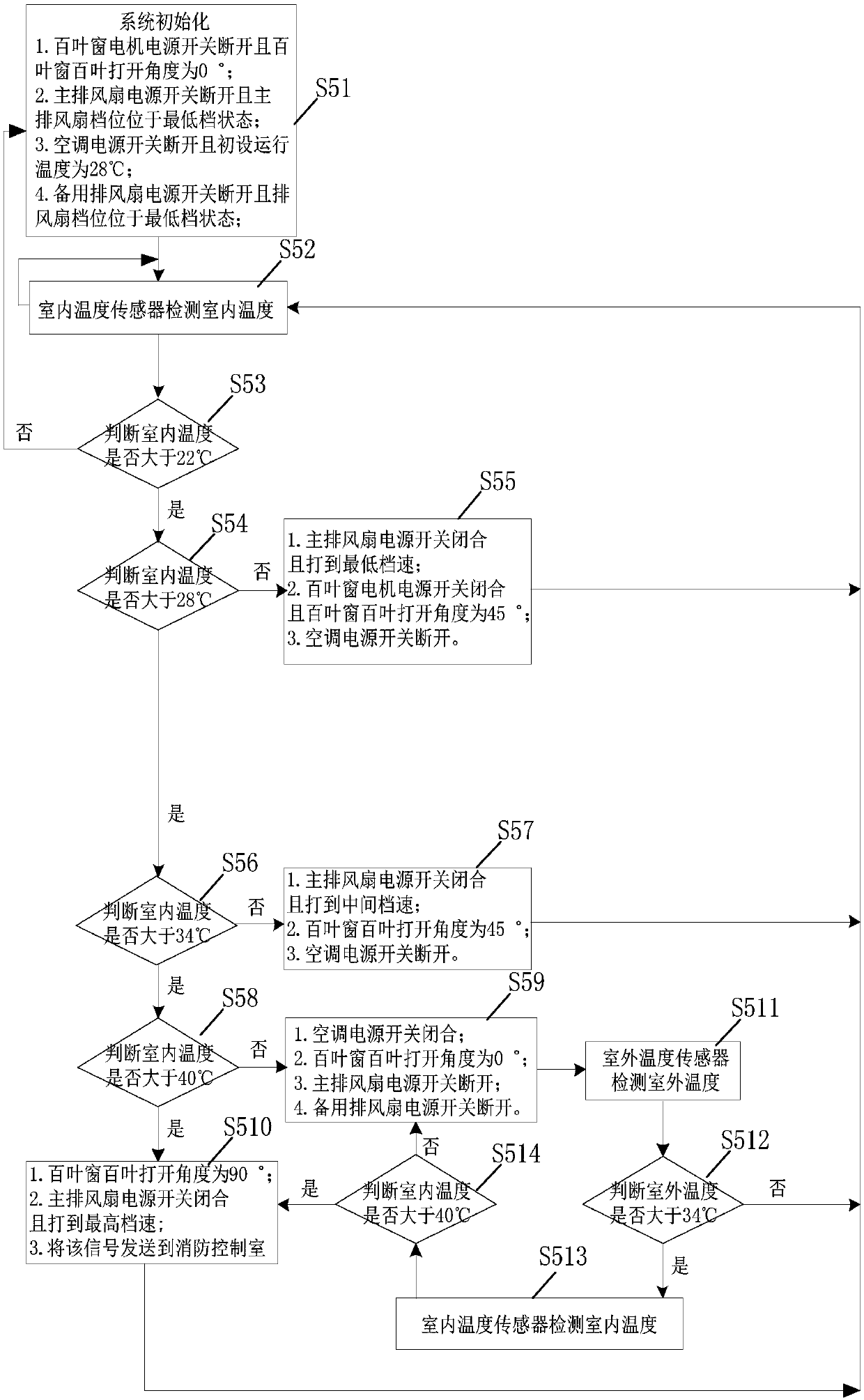

[0077] Based on the elevator machine room temperature intelligent control system in the first embodiment, the present invention also provides an elevator machine room temperature intelligent control method, which will be described in detail below with reference to specific embodiments and accompanying drawings.

[0078] see image 3 , is a flowchart of an embodiment of an elevator machine room temperature intelligent control method of the present invention. Specifically, the elevator machine room temperature intelligent control method of this embodiment includes the steps:

[0079] S51, the elevator machine room temperature intelligent control system is initialized, and step S52 is executed.

[0080] In this embodiment, the initialization of the elevator machine room temperature intelligent control system means that when the indoor temperature is lower than 22°C, the elevator machine room temperature intelligent control system is installed and debugged, and when the debugging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com