Fully-enclosed recycling and automatic disassembly production line for waste refrigerator compressors

A refrigerator compressor, compressor technology, applied in the direction of electronic waste recycling, recycling technology, solid waste removal, etc., to achieve the effect of reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

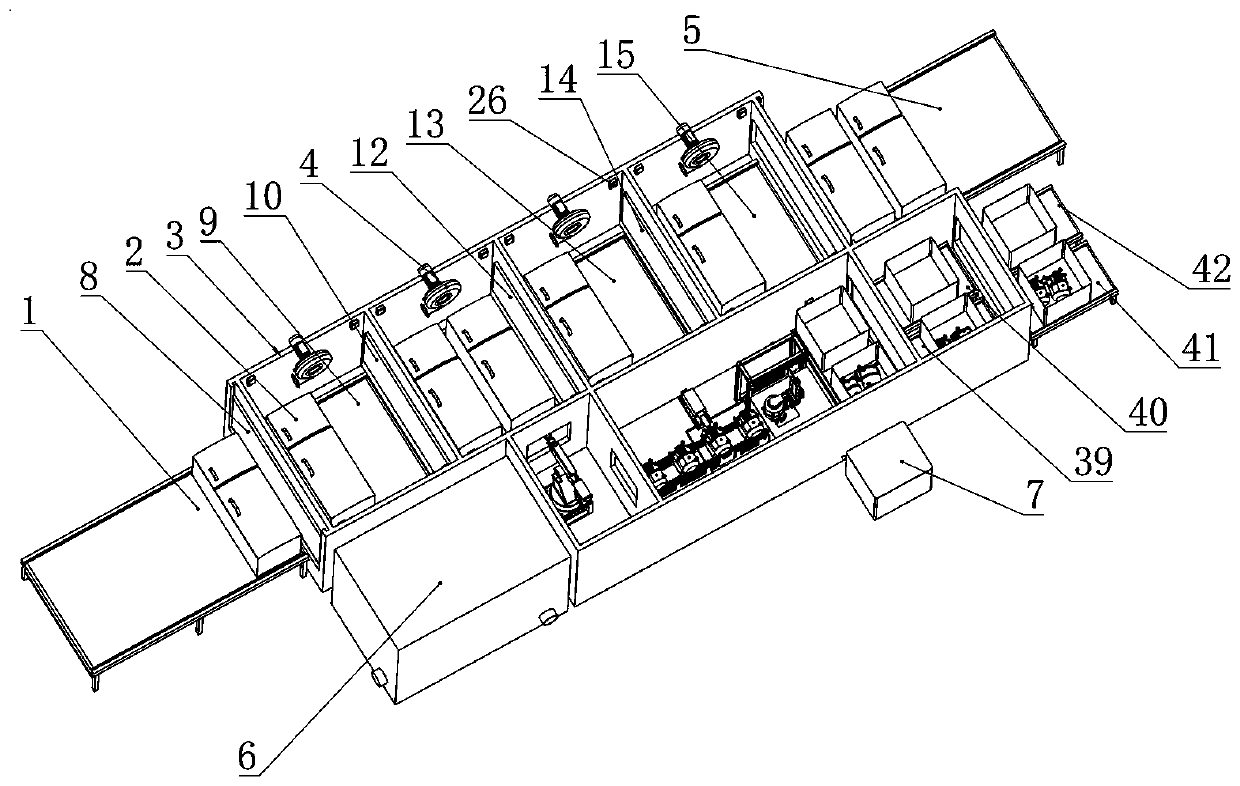

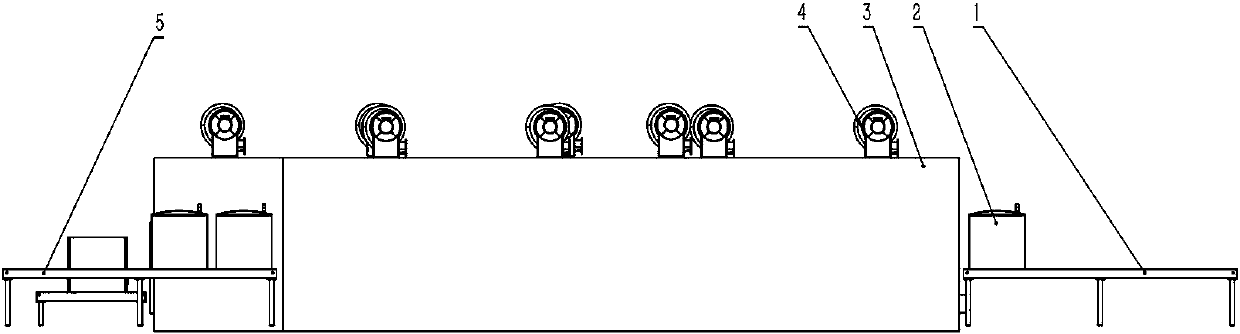

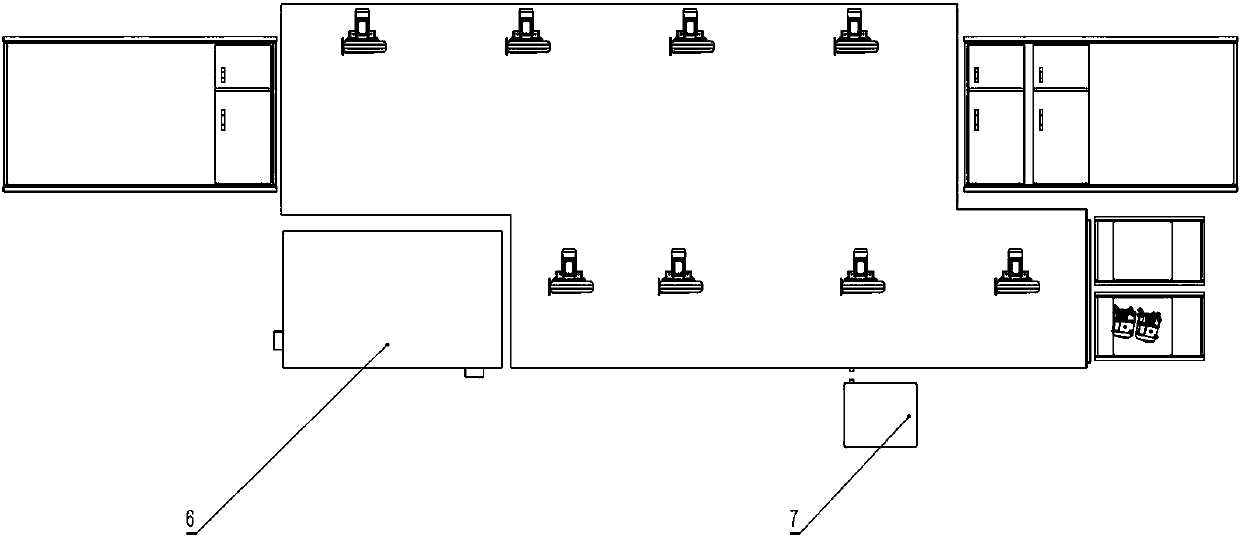

[0038] A fully enclosed recycling and automatic dismantling production line for waste refrigerator compressors, the structure of which is as follows Figure 1-Figure 5 As shown, the control flow is as follows Image 6 As shown, it includes a power supply, an operating system and a PLC control system matched with the operating system; the operating system includes an input transmission device 1 , a continuous airtight processing mechanism 3 and an output transmission device 5 arranged adjacently in sequence. The end of the continuous airtight processing mechanism adjacent to the input conveying device 1 is provided with an input port, and the end adjacent to the output conveying device 5 is provided with an output port, the input port is provided with an automatic door A 8, and the output port is provided with an automatic door E 16; There are three partition walls inside the continuous airtight processing mechanism 3, and the continuous airtight processing mechanism 3 is seque...

Embodiment 2

[0055] A fully enclosed waste refrigerator compressor recovery automatic disassembly production line and production method, the difference from Embodiment 1 is that a sorting robot arm is provided on the side of the delivery belt 41 of the storage box, and the input belt 42 of the storage box One side is equipped with a manipulator for placing the material box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com