Movable magnetic seat drill and bench drill with replaceable electric drill assembly and no guide rail

A technology of drilling without guide rails and magnetic base, which is applied in the direction of large fixed members, other manufacturing equipment/tools, metal processing machinery parts, etc., can solve the problems of work efficiency and work content interference, and achieve high tapping and drilling capabilities, Easy to move and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

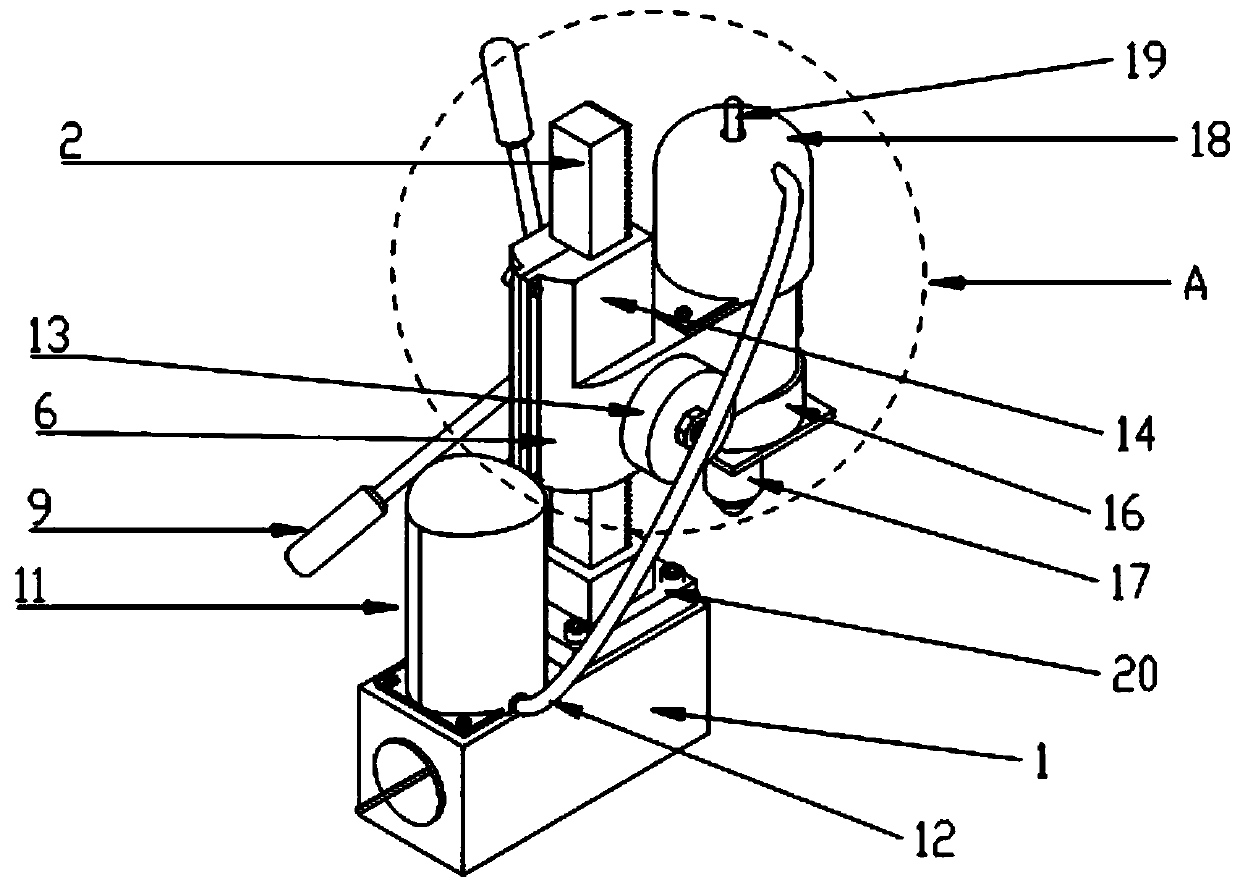

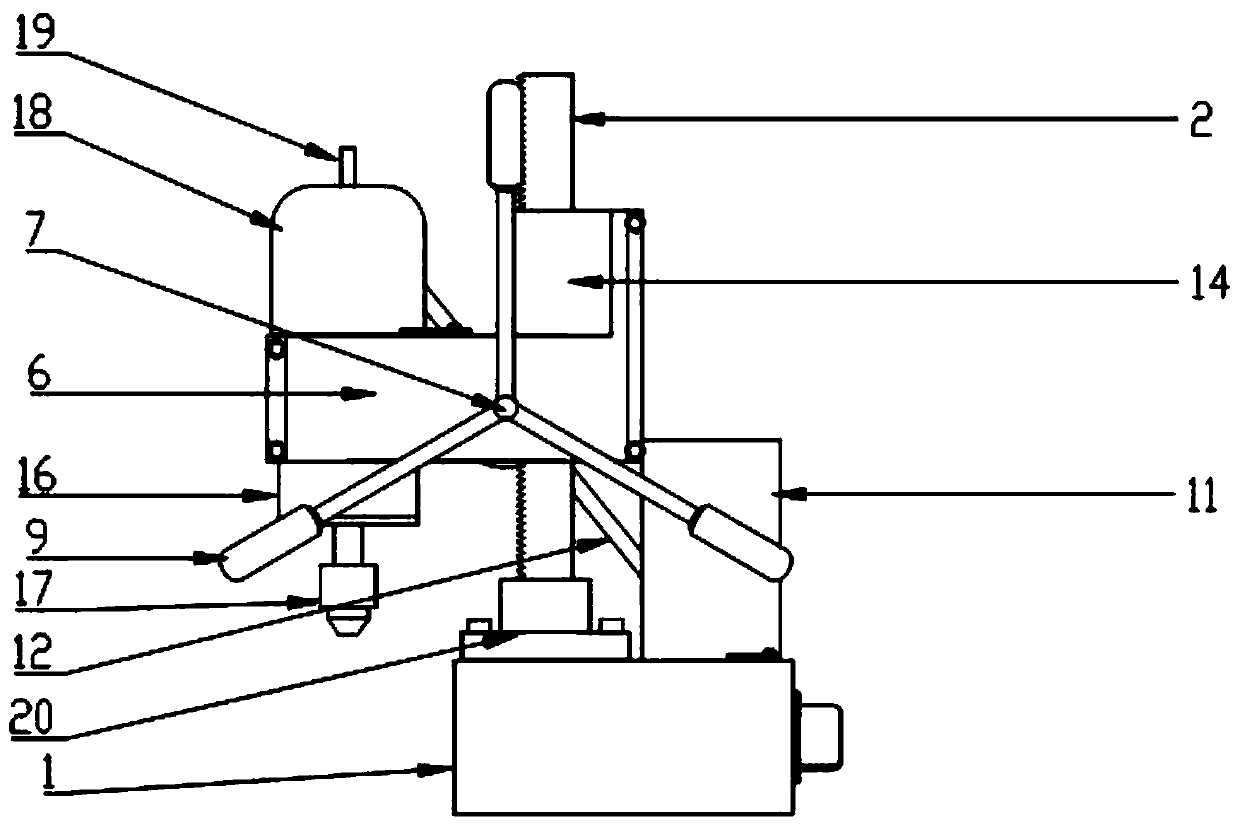

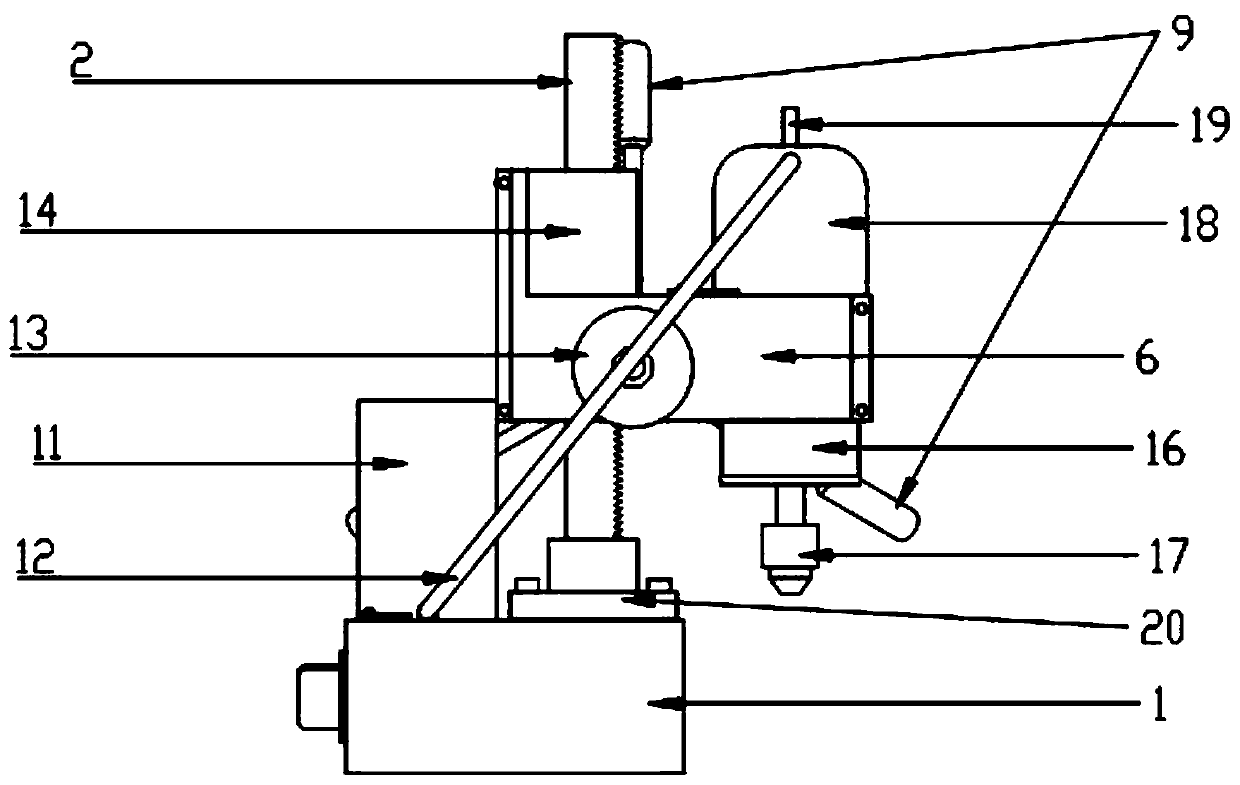

[0048] Such as Figure 1 to Figure 12 As shown, the present invention can replace the electric drill assembly and the movable magnetic base drill without guide rail includes a magnetic base 1, and a rack 2 and a battery 11 are fixedly installed on the magnetic base 1, and the battery 11 can also be installed on the magnetic base. other positions on the side of 1; the installation of the rack 2 can be directly fixedly connected with the magnetic base 1, and the preferred implementation mode in this embodiment is: first install a rack base 20 fixedly connected with it on the magnetic base 1, and the teeth The fixed connection between the bar base 20 and the magnetic base 1 can be welded or bolted, and then the rack 2 is installed on the rack base 20, so that the fixed connection between the rack 2 and the magnetic base 1 is more stable;

[0049]It also includes a machine head clamp 6, which is a whole. In this embodiment, the preferred method is: at least two equal half bodies t...

Embodiment 2

[0052] Depend on Figure 13 As shown, the present invention can replace the electric drill assembly and the movable bench drill without guide rail, its embodiment is to replace the magnetic base 1 with the bottom plate 21 on the basis of embodiment 1, so that the magnetic base drill can be converted into a bench drill.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com