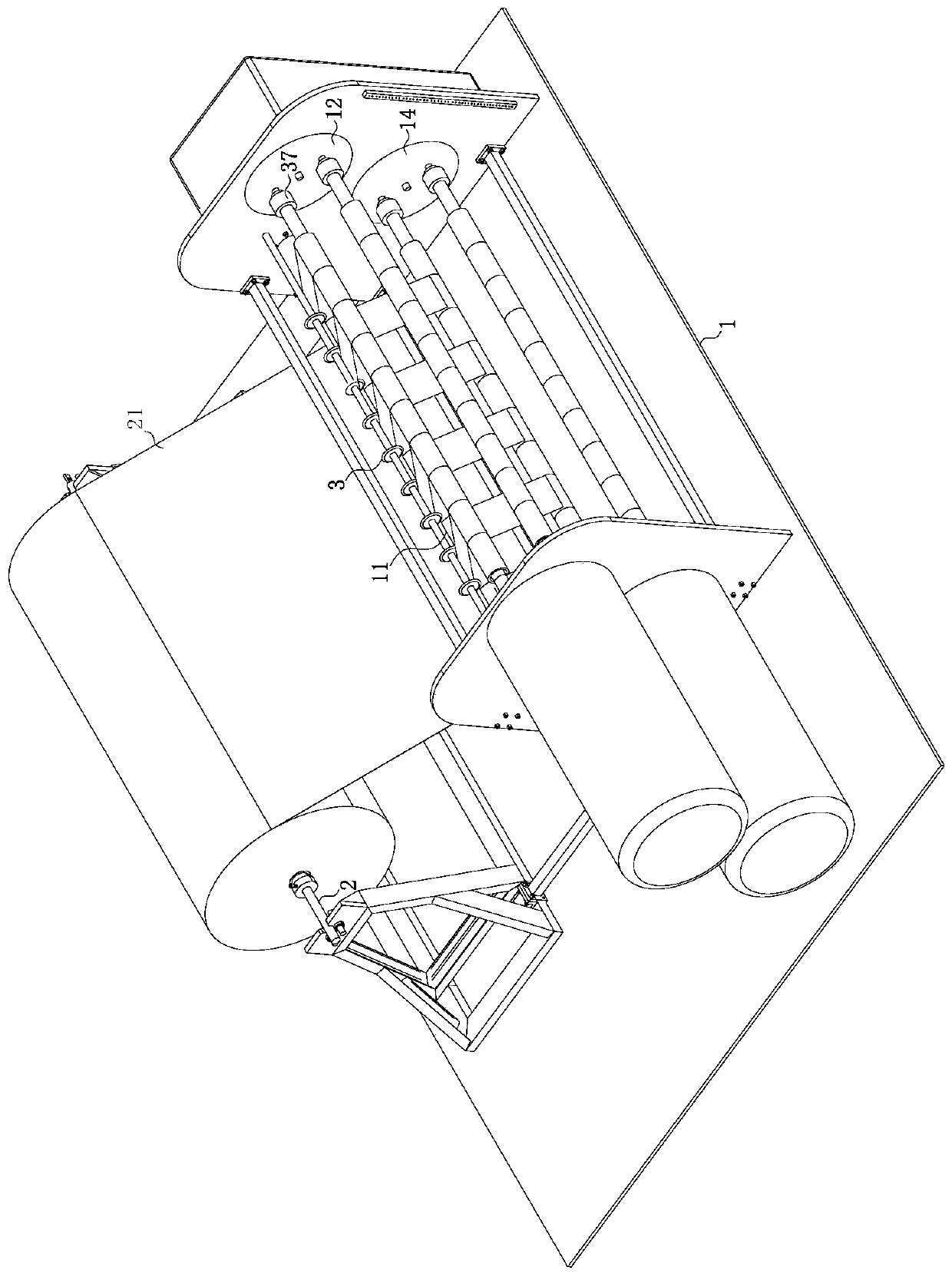

Thin film slitting machine used for thin film production

A slitting machine and film technology, which is applied in the direction of thin material processing, winding strips, sending objects, etc., can solve the problem of reducing the efficiency of the slitting machine, reducing the service life of the slitting machine, and it is difficult to meet the high-efficiency film slitting in large quantities. Production demand and other issues, to achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

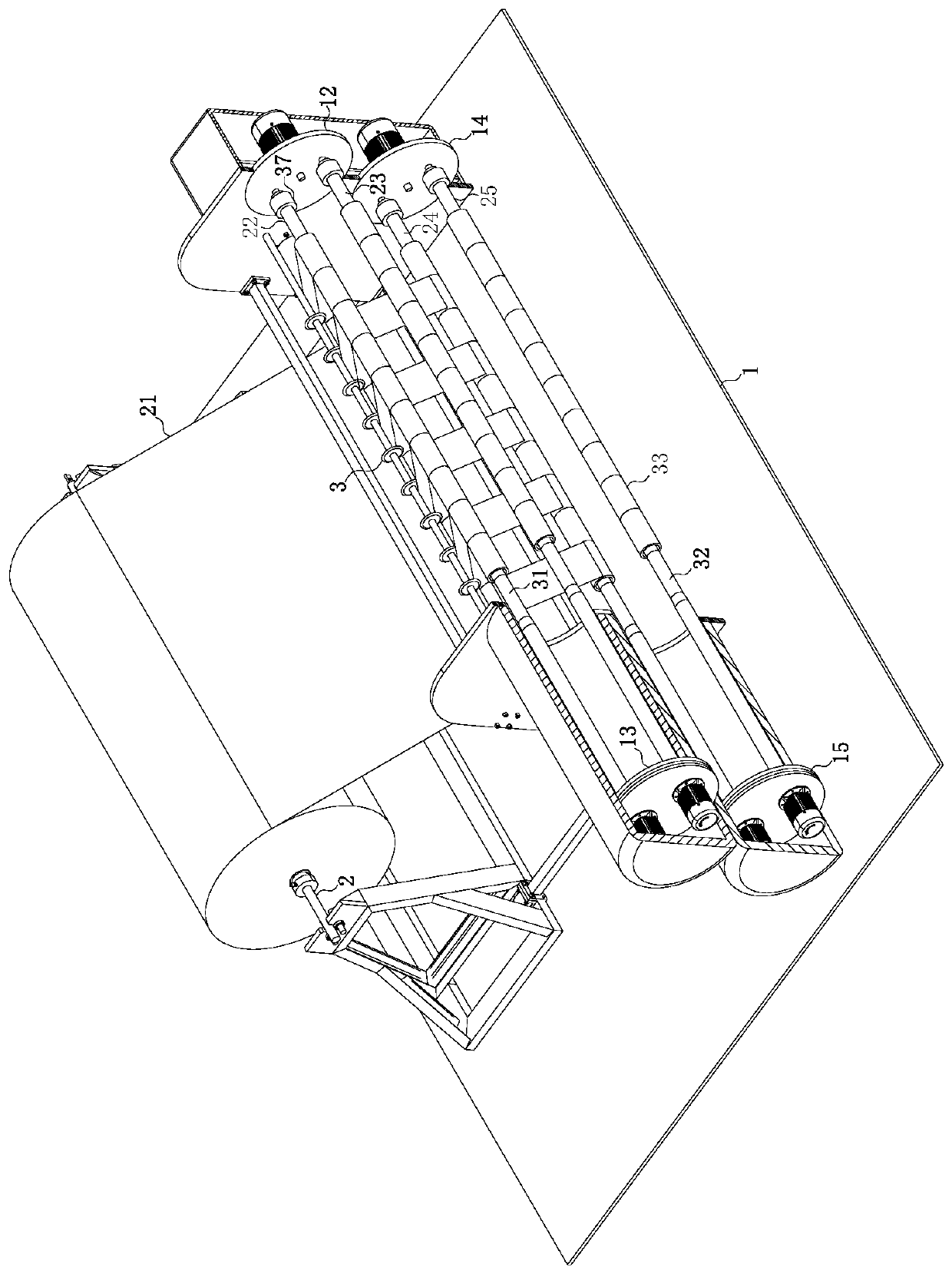

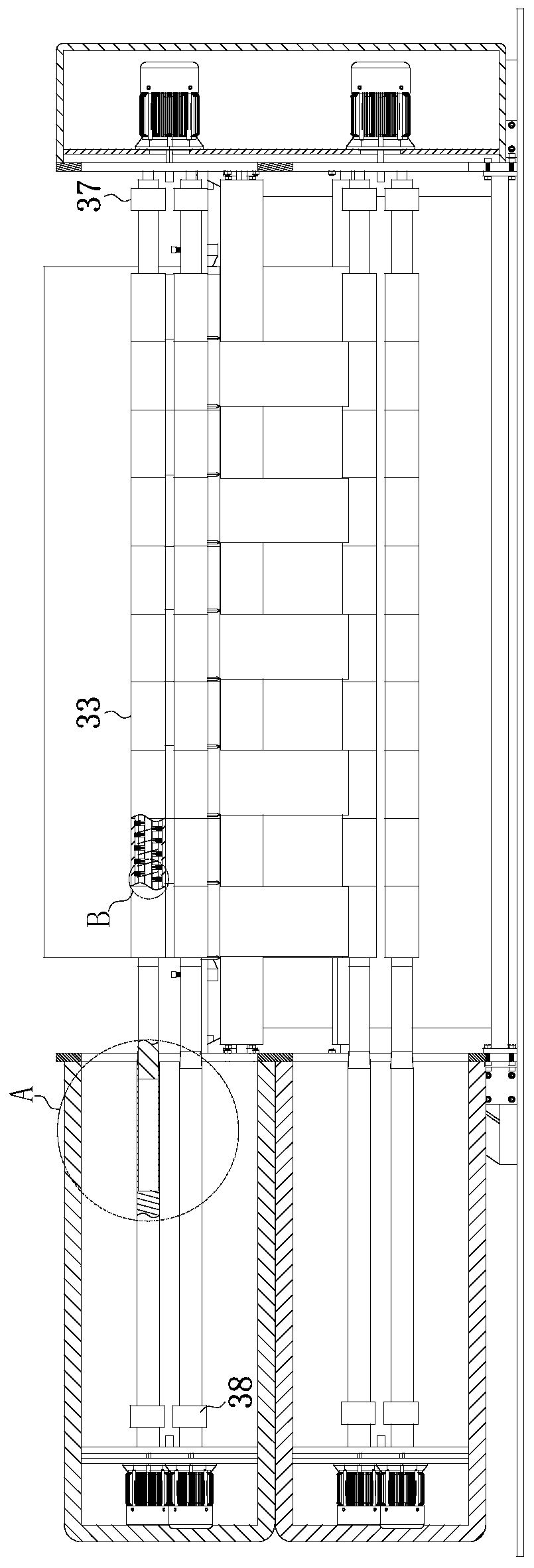

[0026] As an embodiment of the present invention, the surfaces of the first sub-reel 22, the second sub-reel 23, the third sub-reel 24 and the fourth sub-reel 25 are all provided with sliding grooves; A top block 34 is connected; the bottom surface of the sliding groove and the surface of the top block 34 are jointly fixed with the same spring 35; The surface of the reel 24 and the fourth sub-reel 25 is designed with a smooth surface, so after the cover roll 33 is received on the surface, the position is completely fixed, so when the thickness of the cover roll 33 is uneven, the surface cleanliness of the sub-roll film is poor or When the cylindricity of the outer arc surface of the roll 33 is poor, it will seriously affect the tension force of the sub-rolled film on the surface of different sets of rolls 33. When the above factors are superimposed on each other, it is easy to cause the tension force of some sub-rolled films to be relatively low. Larger or smaller, which in tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com