A preparation process of composite porous carbon film and capacitor

A preparation process, porous carbon technology, applied in the preparation/purification of carbon, hybrid capacitor electrodes, ceramic products, etc., can solve the problems of increased internal resistance, increased processing difficulty, etc., to reduce internal resistance, improve volume utilization, reduce The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

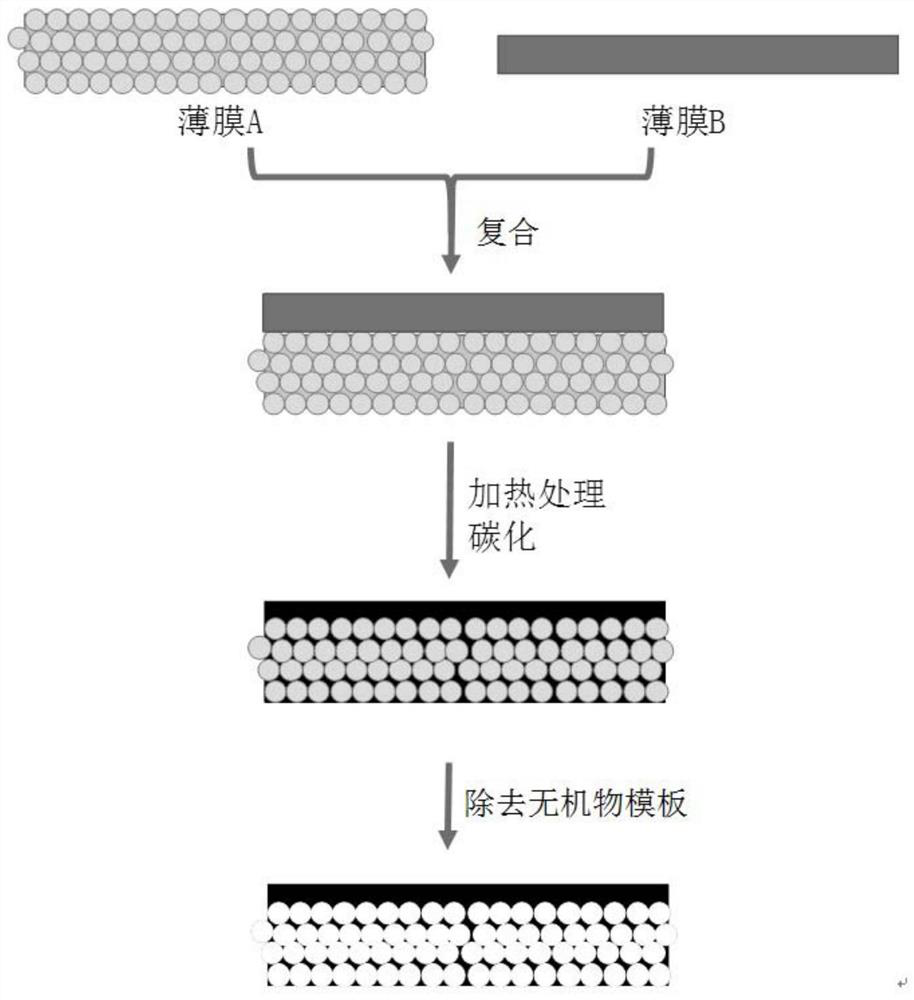

[0062] Such as figure 1 As shown, the specific process of the preparation process of the present embodiment is as follows:

[0063] (1) Preparation of film A

[0064] 50 g of a 10 wt% aqueous solution of polyvinyl alcohol (PVA, 86-89% hydrolyzed), 2 g of 1,3-propanediol (PD), and 2 g of n-butanol were added to the milling jar. After ball milling for 1 hour, the aqueous phase suspension containing 5g of 50nm silica sol and 2g of PD was added into the ball mill jar. After ball milling for 2 hours, the slurry (mixed suspension) was separated and defoamed. The slurry was coated onto a glass substrate by casting with a gap of 0.10 mm between the doctor blade and the substrate. After the water evaporates, the film is peeled off from the substrate to obtain a fresh film A containing SiO2 / PVA / PD.

[0065] (2) Preparation of film B

[0066] 2 g of mesophase pitch (MP) and 4 g of n-butanol were added to the mill jar. After ball milling for 1 hour, 2 g of 1,3-propanediol (PD) and 5...

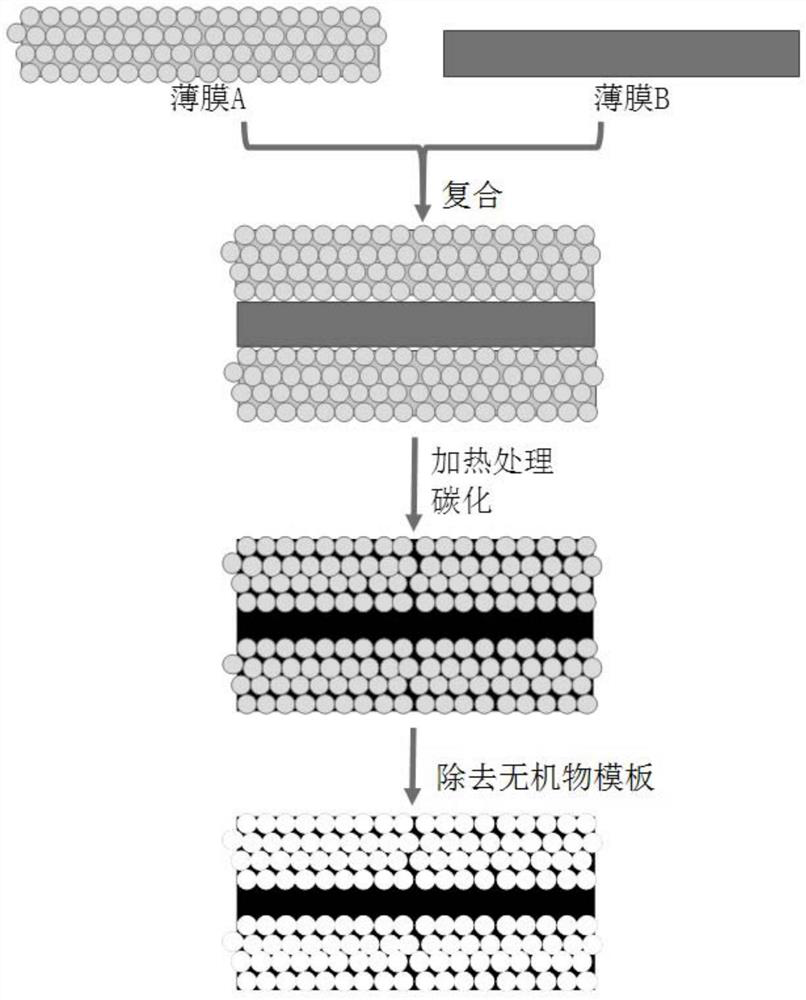

Embodiment 2

[0072] The specific process of the preparation process of this embodiment can be found in figure 2, the preparation process of film A and film B is exactly the same as that of Example 1, the only difference is that when compounding in step (3), the two are laminated together in the mode of A-B-A to form a composite film. In this way, after the same step (4) as in Example 1, a self-supporting double-sided nanoporous film (d-NCS-50, "50" represents the size 50nm of the corresponding silica sol particles) .

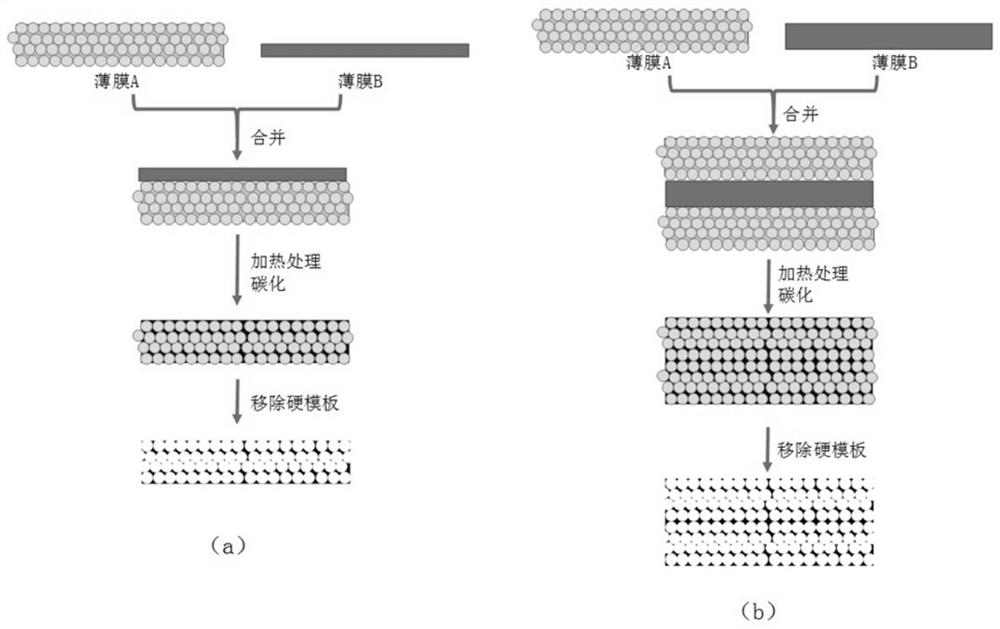

Embodiment 3

[0074] (1) Preparation of film A

[0075] 50 g of 5 wt % polymethyl acrylate (PMMA) in chloroform, 5 g of dibutyl phthalate (DBP) and 2 g of n-butanol were added to the ball mill jar. After ball milling for 1 hour, add 5g of 500nm alumina powder into the ball mill jar. After ball milling for 2 hours, the slurry (mixed suspension) was separated and defoamed. The slurry was coated onto a glass substrate by casting with a gap of 0.10 mm between the doctor blade and the substrate. After the solvent evaporated, the film was peeled off from the substrate to obtain a fresh sheet containing Al 2 o 3 Film A of / PMMA / DBP.

[0076] (2) Preparation of film B

[0077] 2 g of mesophase pitch (MP) and 4 g of chloroform were added to the mill jar. After ball milling for 1 hour, 2 g of DBP and 50 g of 5 wt% PMMA / chloroform solution were added to the ball mill jar. After ball milling for another 2 hours, the slurry (mixed suspension) was separated and defoamed. The slurry was coated ont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com