A safety control method for acidizing operation to prevent packer failure

A safety control and packer technology, applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve problems such as the sealing ability of pipe string joints that do not consider the tensile capacity of the packer, and improve the acidizing operation effect, expand the pressure control window, prevent the effect of seal failure or fracture failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention provides a safety control method for acidizing operation to prevent packer failure, which is used for the safety of operating parameters such as oil pressure, temperature, and casing pressure during the acidizing operation of complex gas wells (three-high gas wells, gas storage wells, etc.) control, improve the effectiveness of acidizing operations, and prevent packer failure.

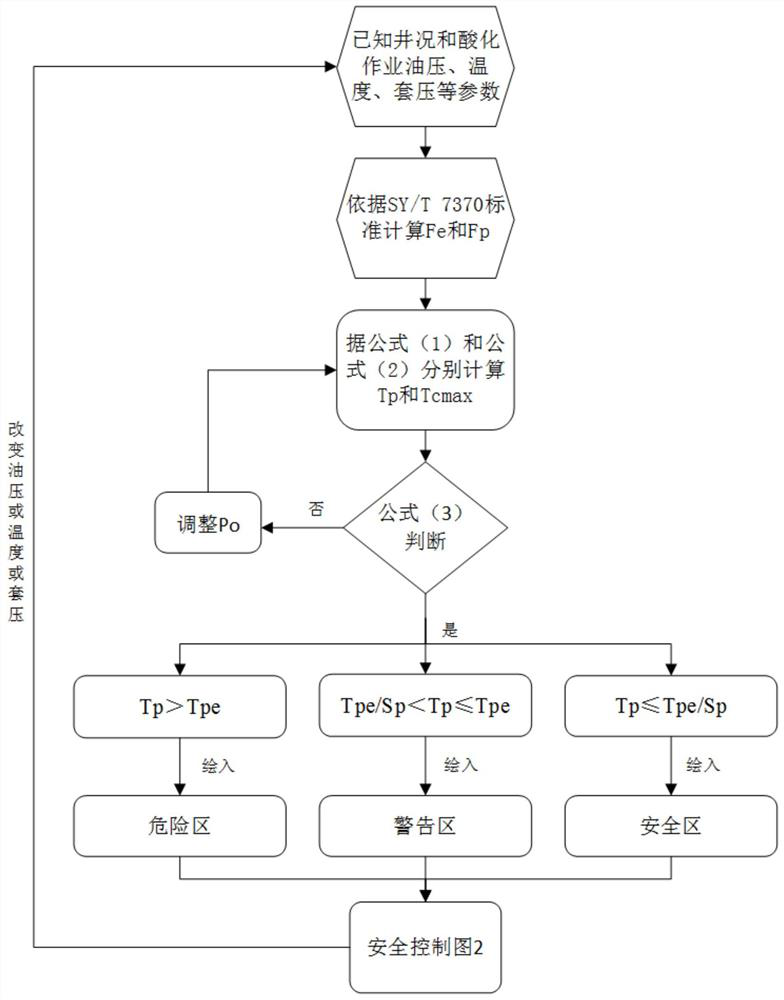

[0036] see figure 1 , the present invention a kind of acidizing operation safety control method that prevents packer failure, comprises the following steps:

[0037] S1. According to the formula (51) in the SY / T 7370 standard, calculate the axial load Fe generated by running and setting the tubing string at any well depth L, and calculate the packer setting depth Lp according to the formula (60) in the SY / T 7370 standard Axial load Fp on the packer;

[0038] S2. Knowing the oil pressure Pi, flow rate Q, temperature T, casing pressure Po, outer diameter D and wall thickness t of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com