Impact type tunnel instant freezer

A quick-freezing machine and impact-type technology, which is applied in the field of impact-type freezing equipment and impact-type tunnel quick-freezing machines, can solve the problems of rapid circulation of unfavorable airflow and unreasonable layout, and achieve the effect of favorable airflow, simple structure, and rapid and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

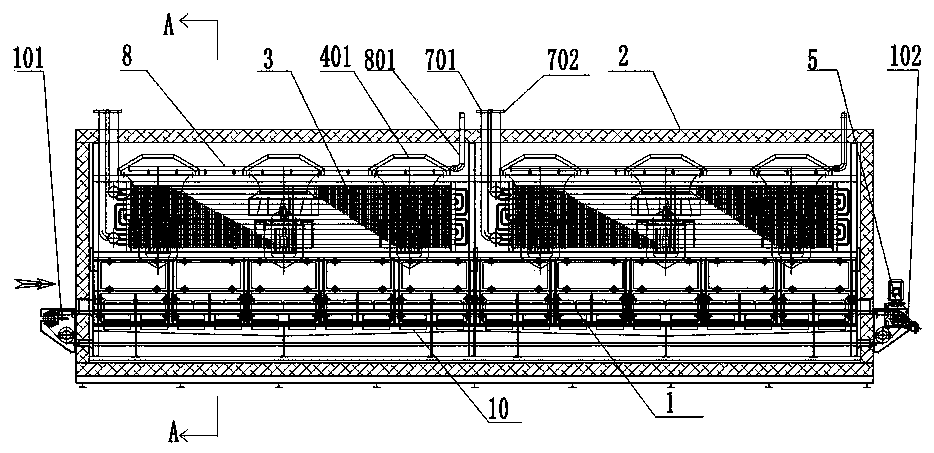

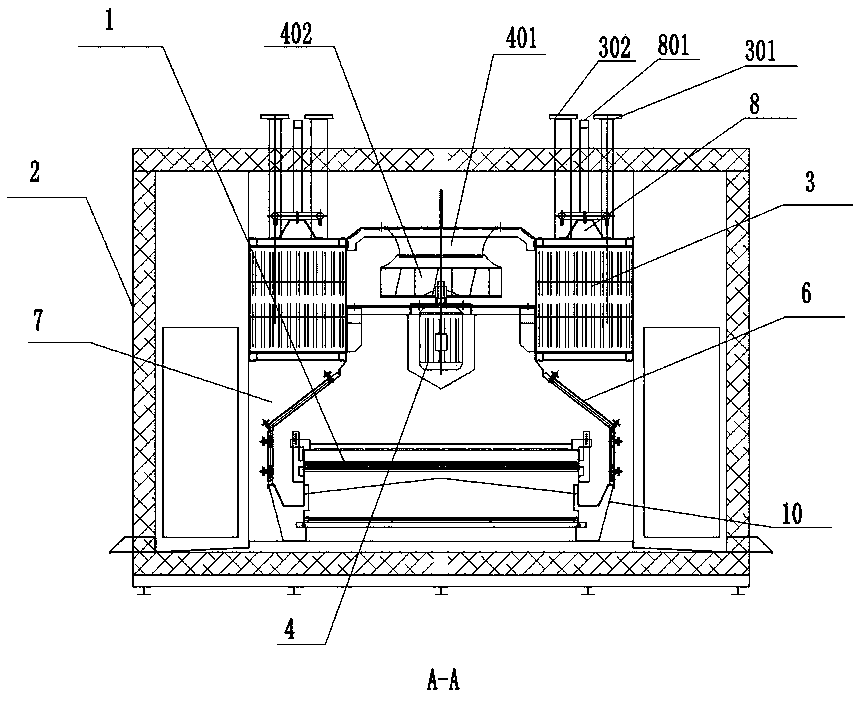

[0024] Such as figure 1 , 2 As shown, an impact tunnel quick-freezing machine includes a conveyor belt 1 for conveying articles, a quick-freezing tunnel 2 through which the conveyor belt passes, and a refrigeration device arranged in the quick-freezing channel, and the refrigeration device includes an evaporator 3 for cooling airflow, The blower fan 4 and the motor 5 that realize the air circulation drive the conveyor belt to circulate, and the articles are placed on the feed end 101 of the conveyor belt, and are sent out from the discharge port 102 after being refrigerated by the air flow. On the article, the upper part of the wind deflector is provided with the fan that communicates with the inner and outer spaces of the wind deflector, and the air inlet 401 of the fan communicates with the lower part of the conveyor belt through the outer air duct 7 outside the wind deflector, that is, the air guide Between the outside of the hood and the tunnel is an outer air duct, on wh...

Embodiment 2

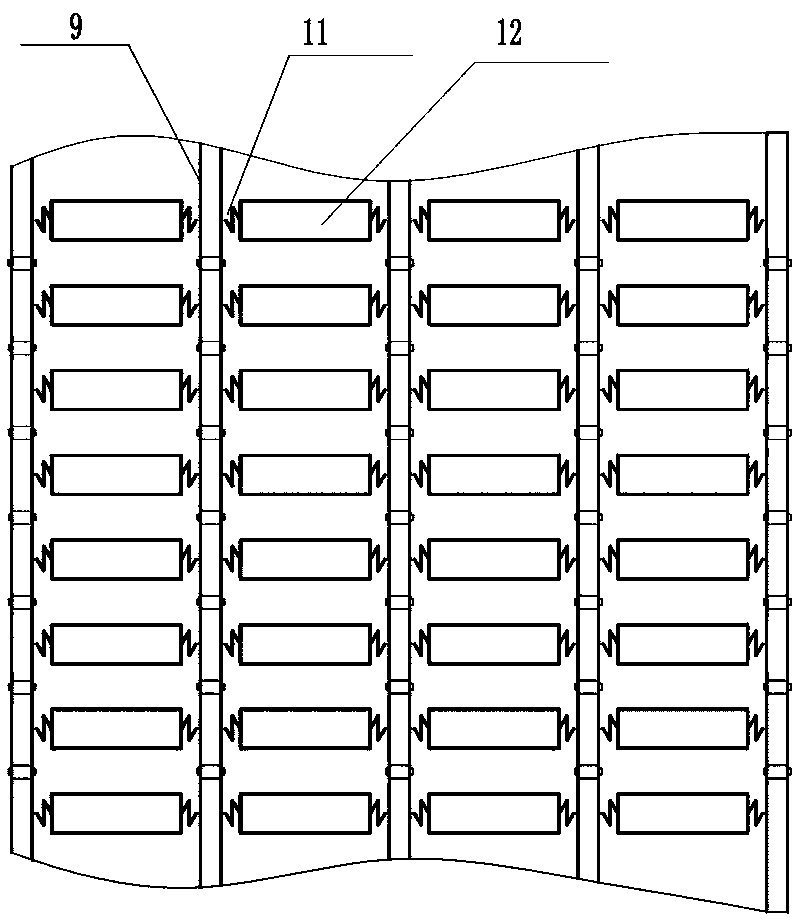

[0026] Such as image 3 , 4 As shown, the conveyor belt includes several parallel chains 9 along the conveying direction, and a turning roller 12 is arranged between the chains, and the two ends of the turning roller are connected with two adjacent chains through temperature deformation elements 11, so that As the temperature changes, the temperature deformation element makes the roller rotate, so as to realize the rotation of the items on the conveyor belt with the temperature change, which is convenient for the rapid cooling and uniform cooling of the items. There is a cavity inside the rotating roller, and a phase-change energy storage medium 13, such as paraffin, is stored in the cavity, so as to realize the continuation of the bottom of the article and supplement the deficiency of the air blown from above; when the article leaves the conveyor belt, the conveyor belt turns When going down, the roller can also absorb the remaining cold energy passing through the airflow of...

Embodiment 3

[0029] Such as Figure 5 , 6 As shown, the temperature deformation element can also be a coil spring 112 (and a planar helical spring) formed by a thermal bimetallic sheet. The spring rotates to drive the roller to rotate. The bimetal sheet is also called a thermal bimetal sheet. Since the thermal expansion coefficients of each component layer are different, when the temperature changes, the deformation of the active layer is greater than that of the passive layer, so that the whole bimetal sheet will bend to the side of the passive layer. , then the curvature of the composite material changes to produce deformation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com