Blasting bead wall material capable of regulating and controlling bursting pressure and method for measuring bursting pressure of blasting bead

A technology of blasting beads and pressure, applied in the direction of using stable tension/pressure to test the strength of materials, measuring devices, analyzing materials, etc., can solve the problems of time-consuming, easily broken beads, affecting product quality, etc., to achieve environmental adaptability Strong, stable, and high-fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

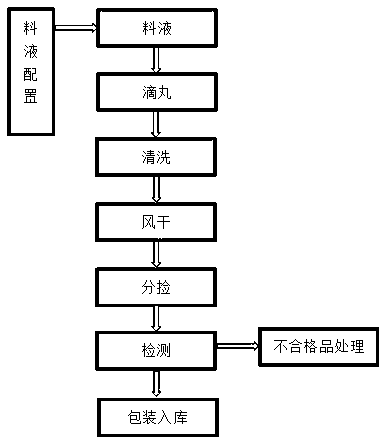

Method used

Image

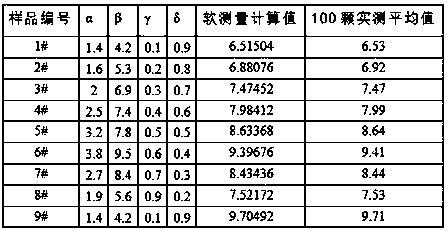

Examples

Embodiment 1

[0059] Take 100 parts of deionized water, 1 part of carrageenan, 0.05 parts of maltodextrin, 4 parts of glycerin, and 0.1 part of brilliant blue. After heating the water to boiling, mix the above materials, disperse them into the hot water, and stir until completely Dissolve without solid impurities, draw a vacuum to make the solution clear and transparent without bubbles, and measure the temperature and viscosity of the wall material glue. Add the glue solution to the drop-making equipment preheated to 70~80°C, adjust the glue feeding speed, flavor speed and glycerin speed, and adjust the total weight of the popping beads, the weight of the rubber skin and the weight of the core material according to the sample requirements to ensure that the size of the popping beads is uniform. No bias. After the dripping is completed, clean the glycerin on the surface of the popping beads with alcohol, soak in the enhancement solution for 8 minutes after cleaning, the ratio of the enhancem...

Embodiment 2

[0062] Take 100 parts of deionized water, 3 parts of gelatin, 0.5 parts of maltodextrin, 7 parts of glycerin, and 0.5 parts of brilliant blue. After heating the water to boiling, mix the above materials, disperse them into hot water, and stir until completely dissolved , without solid impurities, vacuumize the solution to make the solution clear and transparent without bubbles, and measure the temperature and viscosity of the wall material glue. Add the glue solution to the drop-making equipment preheated to 70~80°C, adjust the glue feeding speed, flavor speed and glycerin speed, and adjust the total weight of the popping beads, the weight of the rubber skin and the weight of the core material according to the sample requirements to ensure that the size of the popping beads is uniform. No bias. After the dripping is completed, clean the glycerin on the surface of the popping beads with alcohol, and soak in the enhancement solution for 10 minutes after cleaning. share. After ...

Embodiment 3

[0065] Take 100 parts of deionized water, 2 parts of gum arabic, 2 parts of pectin, 1 part of maltodextrin, 2 parts of glycerin, 8 parts of sorbitol, 0.8 parts of tartrazine, and 0.2 parts of carmine. After heating the water to boiling, After mixing the above materials, disperse them into hot water, stir until completely dissolved, without solid impurities, draw a vacuum to make the solution clear and transparent without bubbles, and measure the temperature and viscosity of the wall material glue. Add the glue solution to the drop-making equipment preheated to 70~80°C, adjust the glue feeding speed, flavor speed and glycerin speed, and adjust the total weight of the popping beads, the weight of the rubber skin and the weight of the core material according to the sample requirements to ensure that the size of the popping beads is uniform. No bias. After the dripping is completed, clean the glycerin on the surface of the popping beads with alcohol, soak in the enhancement soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com