A multi-carrier AGV control system capable of omnidirectional movement and its control method

An omnidirectional movement and control system technology, applied in the multi-load AGV control system and its control field, can solve the problems such as insufficient use, insufficient stability of the mecanum wheel, uncontrolled system design and description, etc., to achieve good accuracy and stability. , Strong follow-up expansion, good accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

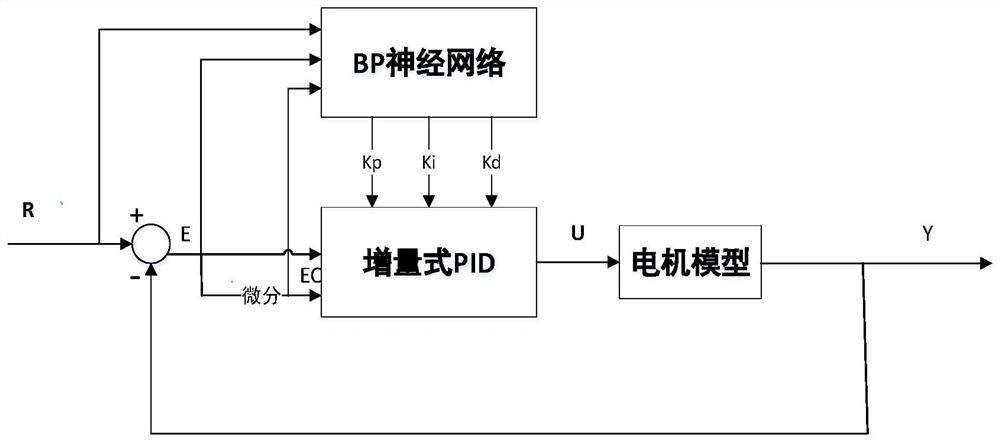

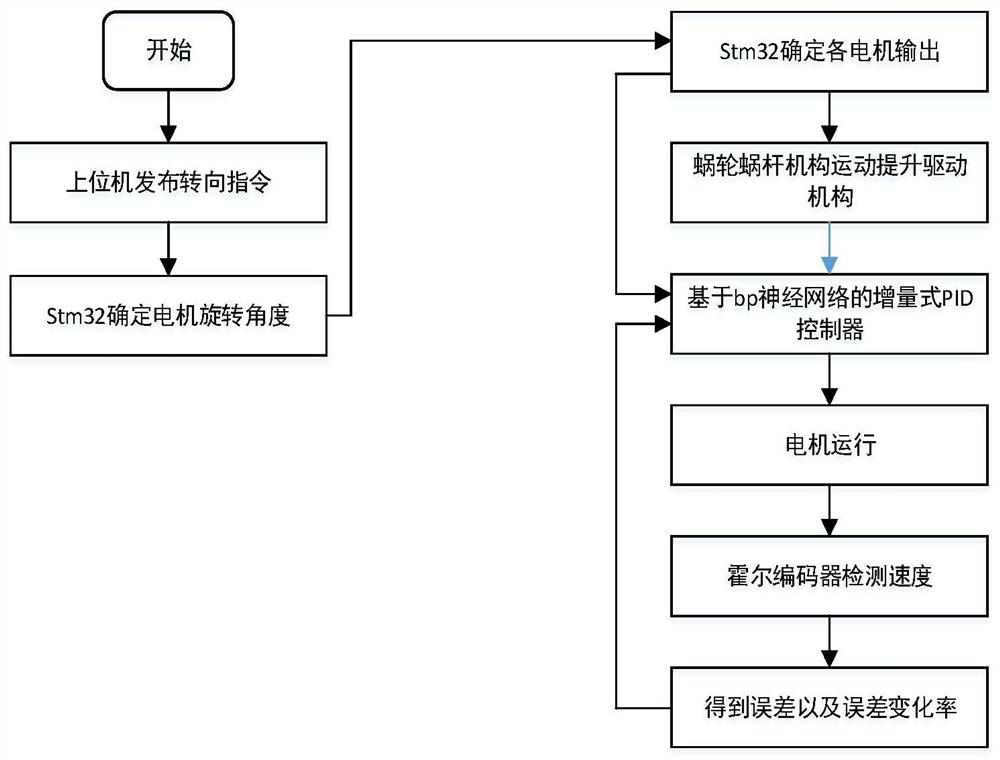

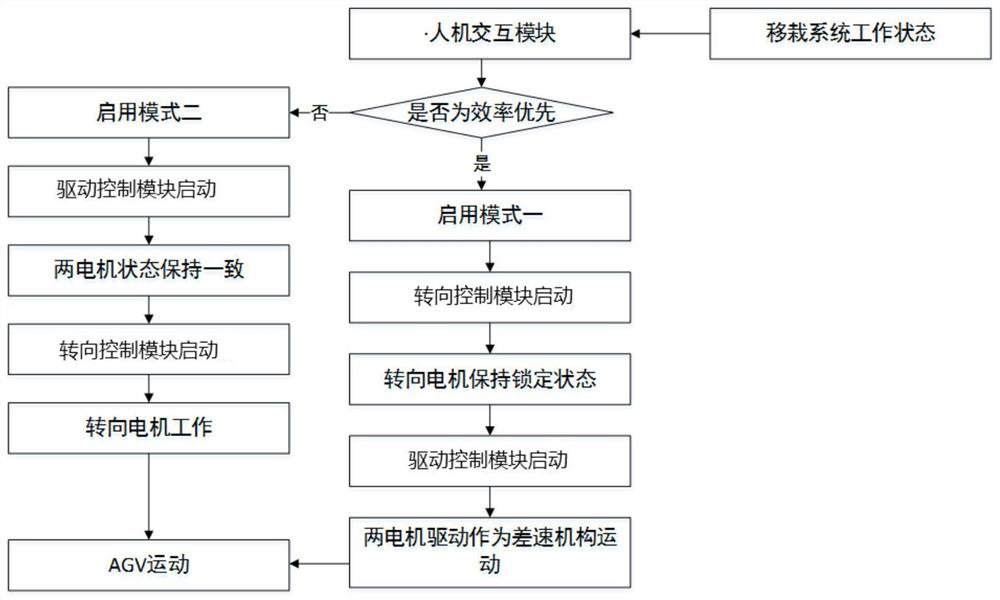

[0053] Embodiment: An omnidirectional mobile multi-carrier AGV control system is composed of a main control module, a steering control module, a drive control module, a multi-cargo transfer module, a human-computer interaction module, a power supply module and a communication module; the main control module uses In order to control the execution of the predetermined task of the AGV, the incremental PID method of the BP neural network is used to realize the precise steering of the AGV and supply power to the power module; the steering control module is used to control the precise steering of the AGV and is electrically connected to the main control module; the drive control module , used to control the AGV to move forward and backward at a certain speed; electrically connected to the main control module; the multi-cargo transfer module, used to control the AGV to move to the place where the goods are to be picked up to accurately take out the items on the shelf, and electrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com