Fault location visualization system and method based on operation and maintenance data prediction

A technology for fault location, operation and maintenance data, applied in electrical digital data processing, error detection/correction, instruments, etc. It can solve problems such as heavy workload, excessive log information data, and high risk, and achieve accurate prediction and positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

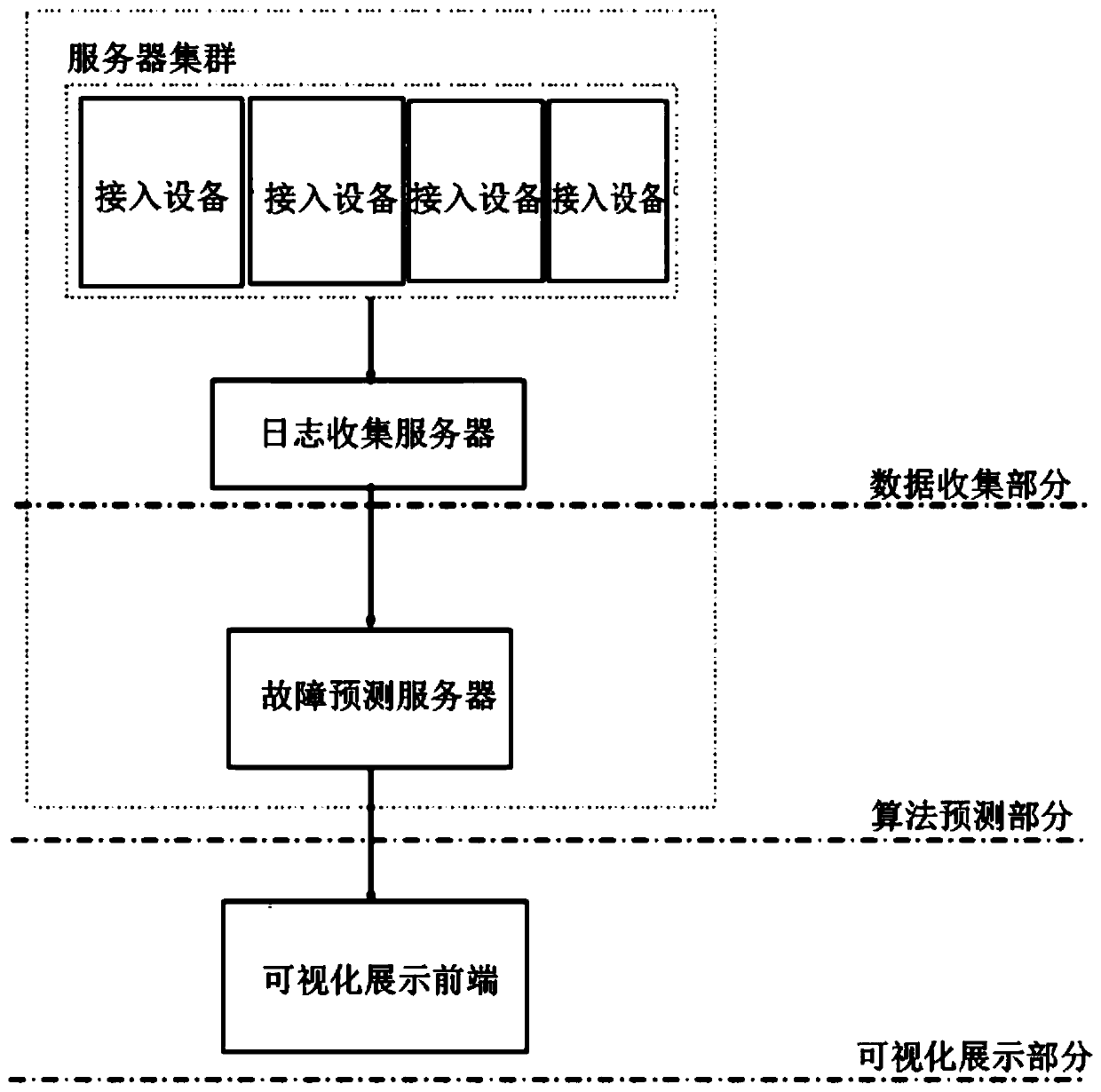

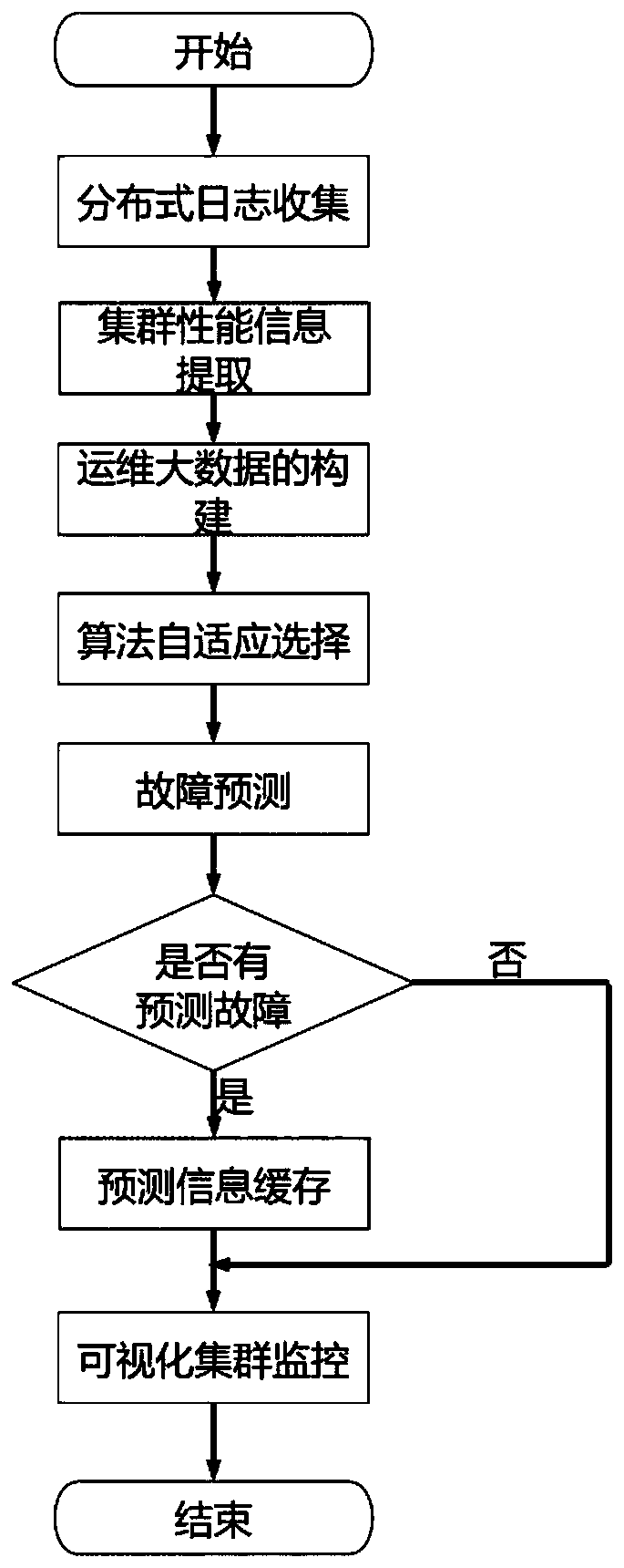

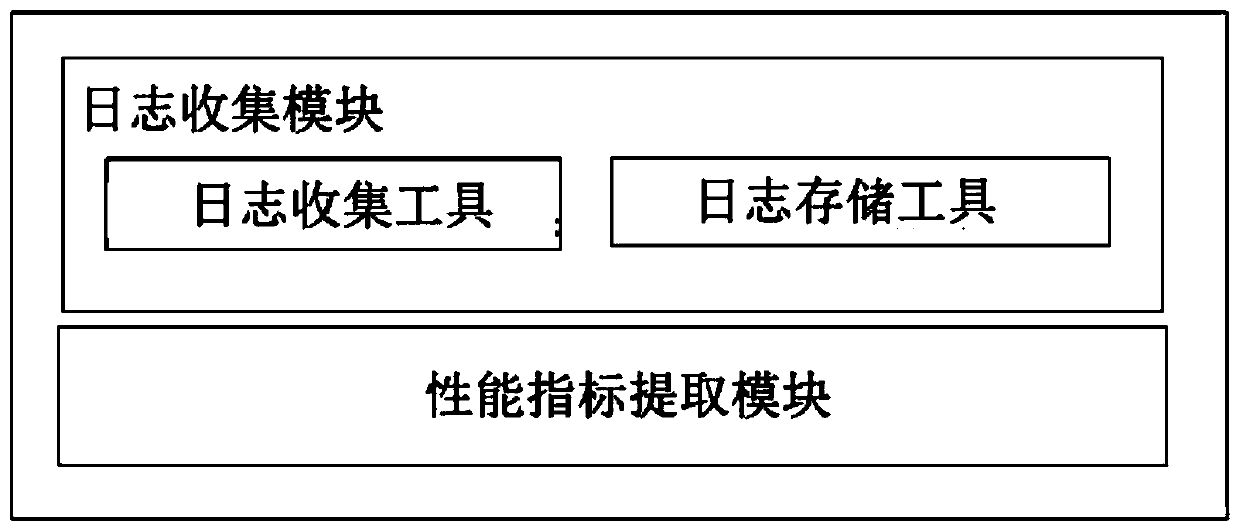

[0039] The present invention first uses a distributed log collection framework to collect machine log information on each device, and then extracts key information from the machine log information as the performance index of the machine at that time, and constructs big data for operation and maintenance. Afterwards, the processed operation and maintenance big data is used to train the artificial intelligence model. When the latest real-time performance data is input, the model can predict whether these machines will fail in the next period of time, and the graph will be displayed It can be visualized to the operation and maintenance personnel in the form of tables and tables, helping the operation and maintenance personnel to identify problems and prepare solutions in advance, thus solving the problem that the operation and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com