Resistive memory and manufacturing method thereof

A technology of resistive variable memory and manufacturing method, which is applied in the direction of electrical components, etc., can solve problems such as device failure, high programming energy consumption, incomplete reset, etc., to reduce current and instantaneous power consumption, improve low-resistance state resistance, reduce The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

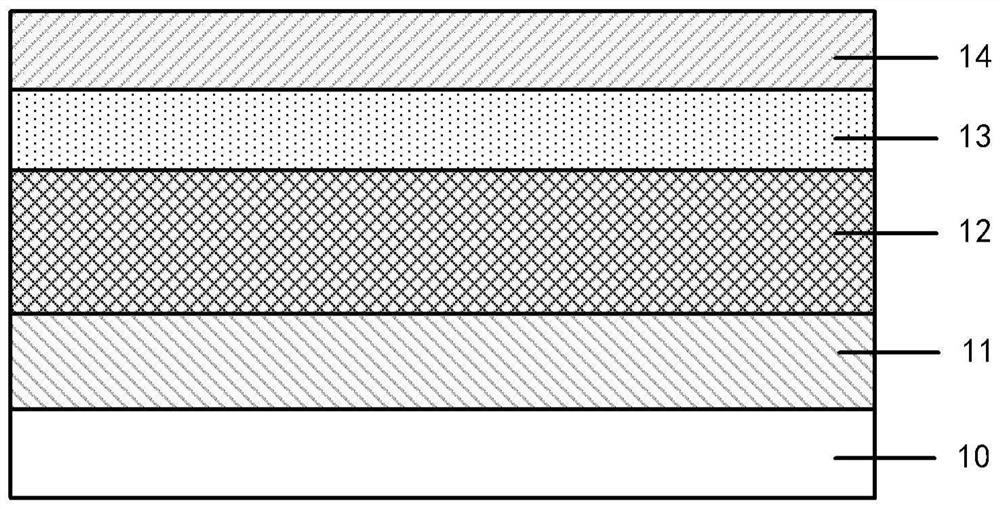

Embodiment Construction

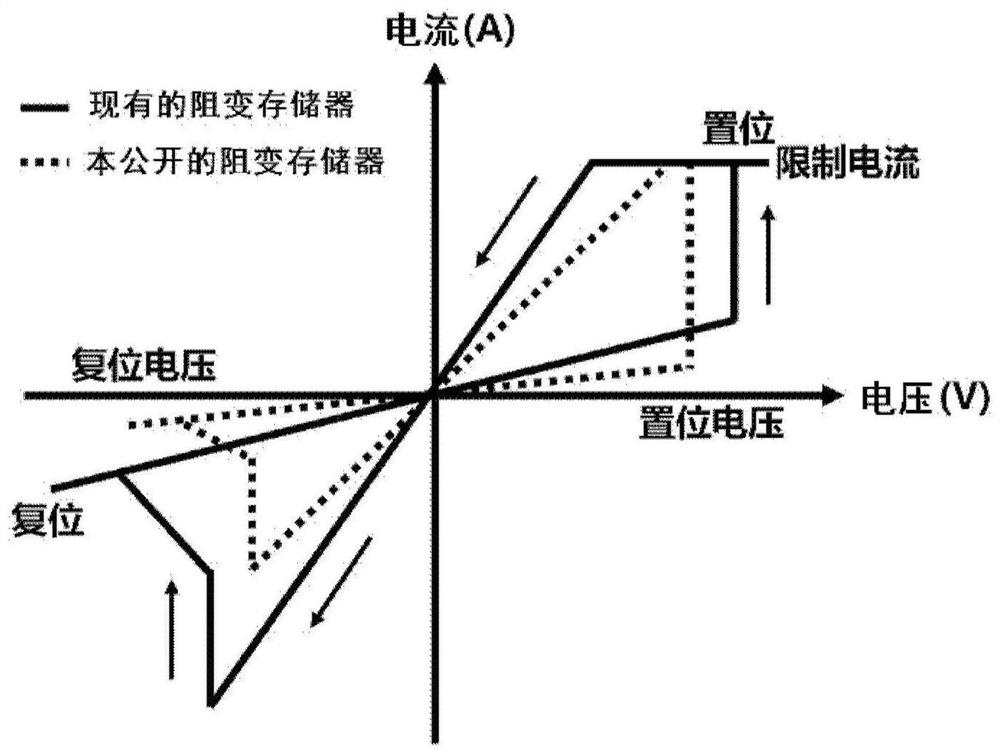

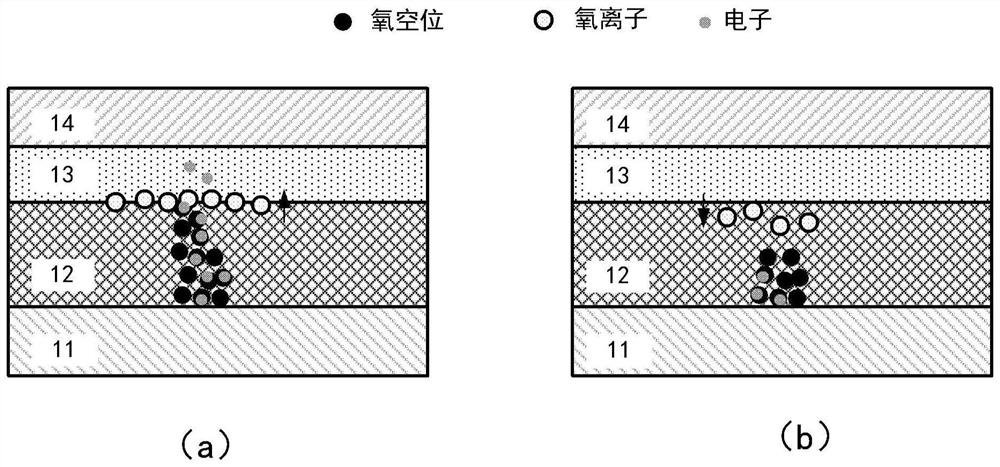

[0031] The current explanation of the mechanism of oxide-type RRAM is mainly based on the principle of oxygen vacancy conductive filaments. The resistive switching process is completed by the continuous formation and rupture of conductive filaments near the top electrode when voltages of different polarities are applied.

[0032] The inventors found that in the resistive switching process, due to the existence of excess oxygen vacancies generated by the electric field, and the oxidized cathode (as an oxygen storage layer) in the reset (RESET) process cannot release enough oxygen ions to the oxygen in the conductive filament. The recombination of vacancies leads to incomplete RESET of the device, and as the number of cycles increases, the concentration of oxygen vacancies near the top electrode continues to increase, which further deteriorates the RESET process and eventually causes device failure. Moreover, due to the accumulation of oxygen vacancies, the size of the conductive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com