Compressor and refrigeration device

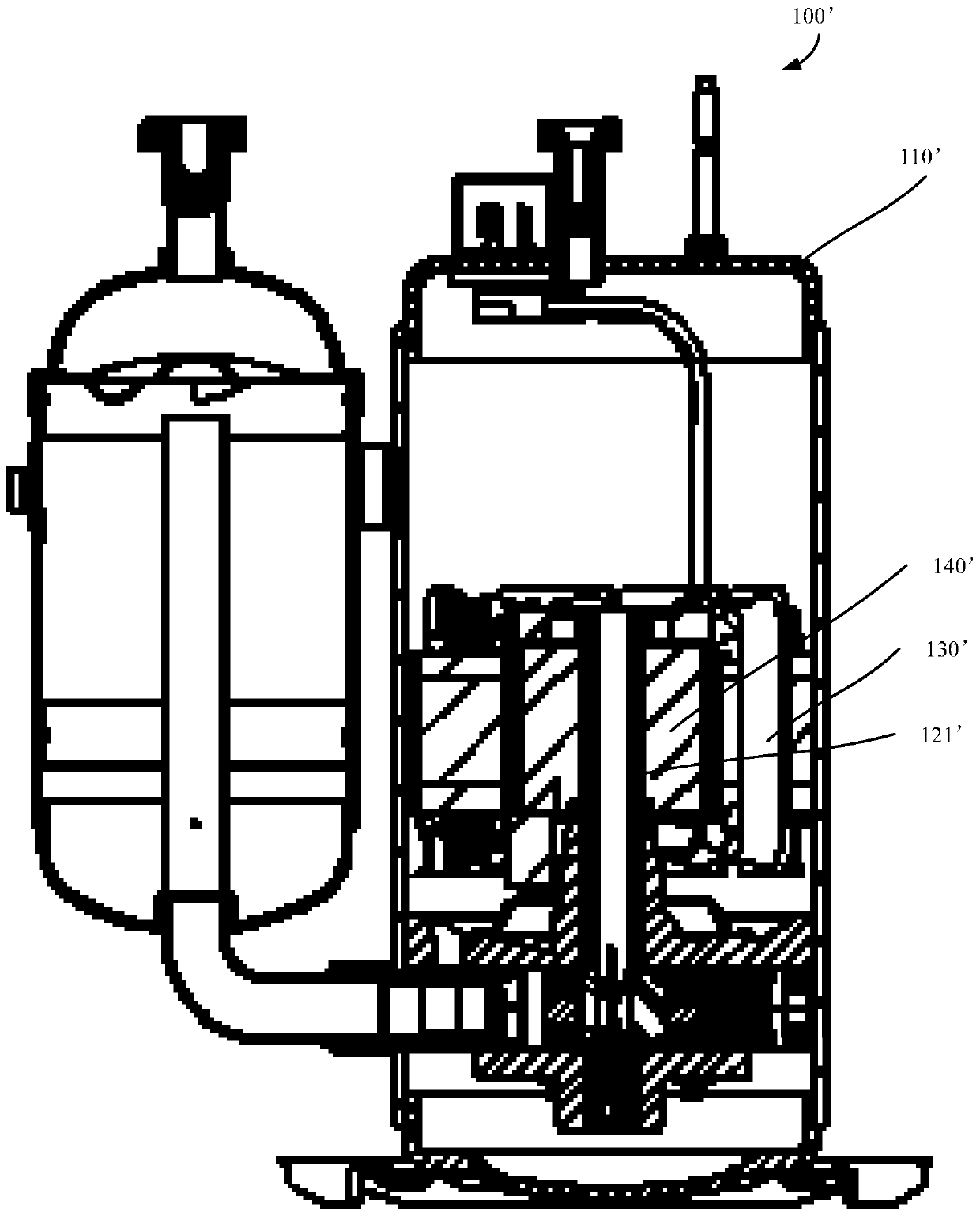

A compressor and motor assembly technology, which is applied in the field of compressors, can solve problems such as unfavorable vibration, large height of compressor 100', high center of gravity, etc., and achieve the effects of reducing stress, realizing miniaturized design, and reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

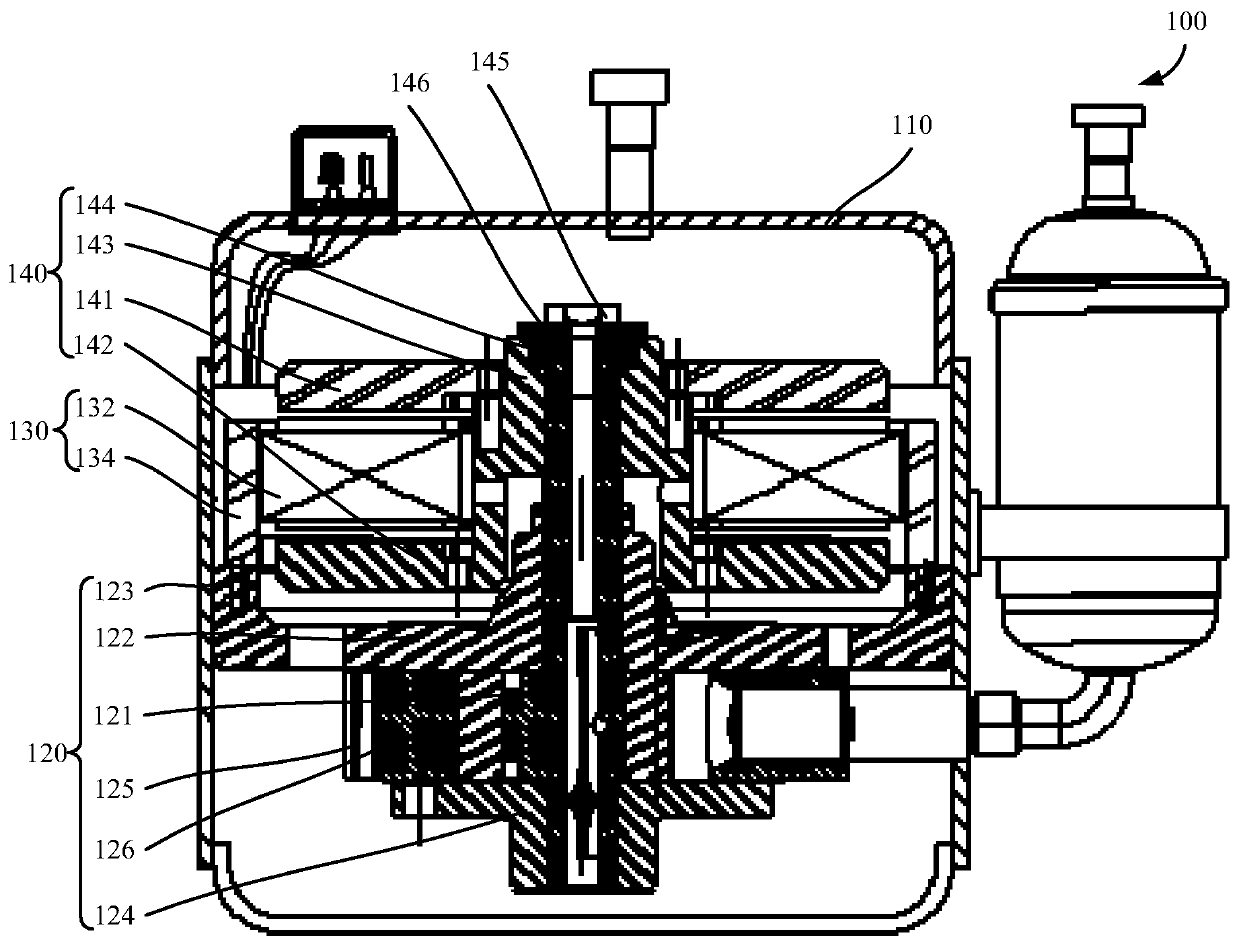

[0059] Such as figure 2 As shown, according to the first aspect of the present invention, the present invention provides a compressor 100, the compressor 100 includes a casing 110, a pump body assembly 120 and a motor assembly, and the pump body assembly 120 includes a crankshaft 121 and an upper bearing 122; The motor assembly includes a stator assembly 130 and a rotor assembly 140. The stator assembly 130 is fixed on the upper bearing 122. The rotor assembly 140 is connected to the crankshaft 121. The rotor assembly 140 drives the crankshaft 121 to rotate and compress. The rotor assembly 140 is arranged on the shaft of the stator assembly 130. direction.

[0060] The compressor 100 provided by the present invention includes a casing 110, a pump body assembly 120 and a motor assembly, wherein the pump body assembly 120 includes a crankshaft 121 and an upper bearing 122, the motor assembly includes a stator assembly 130 and a rotor assembly 140, and the stator assembly 130 is...

Embodiment 2

[0063] On the basis of embodiment one, further, as Figure 5 and Figure 6 As shown, the stator assembly 130 includes a stator core set 132 and a stator support 134, the stator support 134 is connected with the stator core set 132, the stator support 134 is connected with the upper bearing 122 and abuts against the upper bearing 122, specifically, the stator support 134 can be connected to the upper bearing 122. A fixing structure is arranged on the bracket 134, so that the stator bracket 134 can be fixed on the upper bearing 122, so that the stator core group 132 connected with the stator bracket 134 is also fixed on the upper bearing 122, that is, through the stator bracket 134 and the upper bearing The connection of 122 realizes the fixation of the stator assembly 130, so the motor assembly as a whole has no contact with the housing 110, and there is no need to fix the motor assembly and the housing 110 in the shrink fit method in the related art, so that the fixing method ...

Embodiment 3

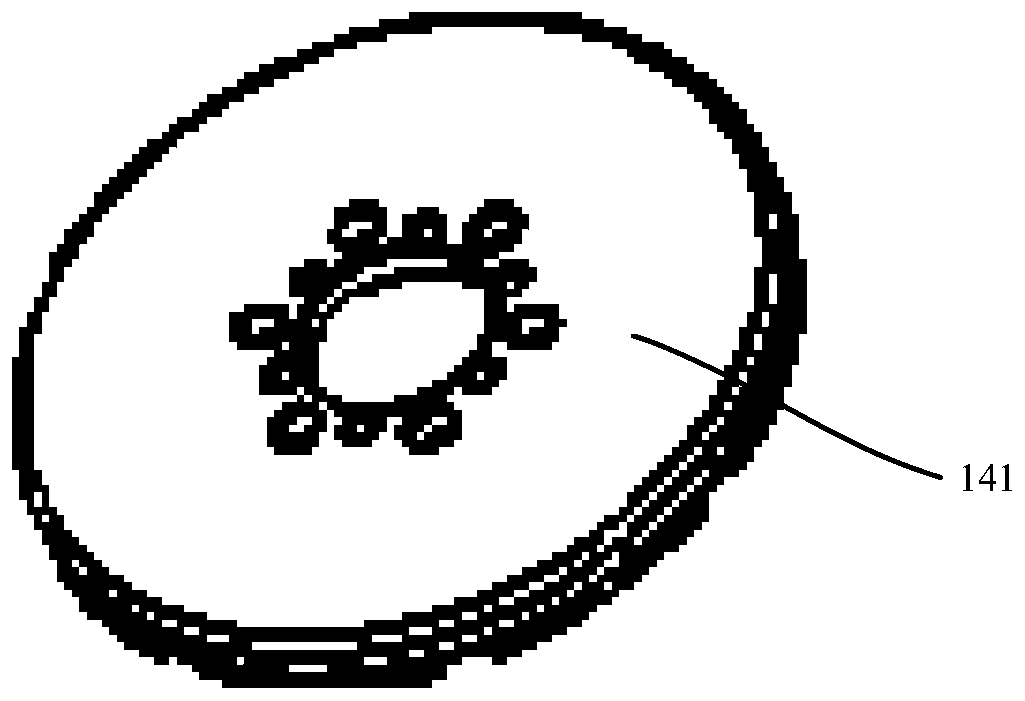

[0066] On the basis of any of the above embodiments, further, as figure 2 , image 3 and Figure 4 As shown, the rotor assembly 140 includes: a first rotor disk 141 disposed on one side in the axial direction of the stator assembly 130; a second rotor disk 142 disposed on the other side of the stator assembly 130 in the axial direction; The bracket assembly connects the first rotor disk 141 and the second rotor disk 142 , the rotor bracket assembly is sleeved on the crankshaft 121 and can drive the crankshaft 121 to rotate.

[0067] In this embodiment, the rotor assembly 140 includes a first rotor disk 141, a second rotor disk 142 and a rotor bracket assembly, wherein the first rotor disk 141 is arranged on one side in the axial direction of the stator assembly 130, and the second rotor The disk 142 is disposed on the other side of the stator assembly 130 in the axial direction, and by respectively arranging the first rotor disk 141 and the second rotor disk 142 on both sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com