Disposable mask machine debugging process

A disposable mask technology, applied to sewing tools, protective clothing, clothing, etc., can solve problems such as poor debugging accuracy, limited debugging range, affecting the smoothness of mask machine use and mask production efficiency, so as to avoid blanks The effects of waste, wide debugging range, and clear debugging operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

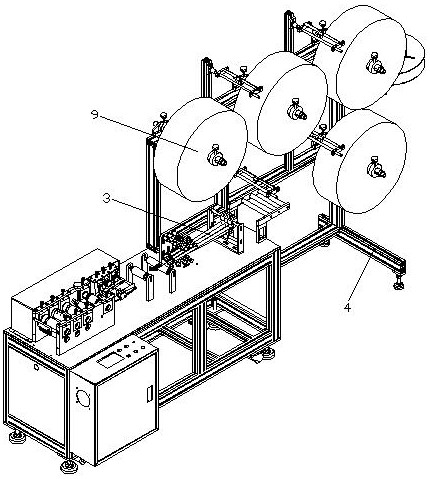

[0044] see Figure 1-Figure 5 , the debugging process of disposable mask machine, including the following steps:

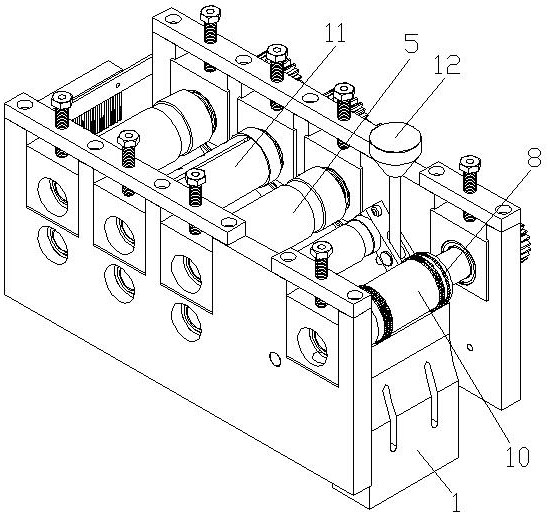

[0045] a. General assembly adjustment, the upper top surface of the ultrasonic welding head 1 is raised by 4mm relative to the supporting plate 2;

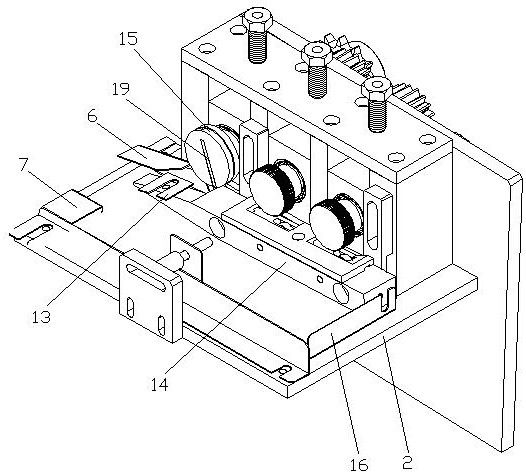

[0046] b. Adjust the pleat deflector 3, adjust the mutual positions of the 6 pleat deflectors 3, so that the width of the 3 layers of pleats is 8mm, and the 3 layers of pleats are connected at the first place in the width direction;

[0047]c. Wear the cloth and test the cloth running resistance at the pleat deflector 3, put the mask cloth roll on the material rack 4, the mask cloth passes through the pleat deflector 3, use a spring scale to pull the cloth, and test the cloth running resistance within 1Kg;

[0048] d. Adjust the stability of the automatic cloth running. The cloth passes through each roller in turn, adjust the main traction roller 5, use a feeler gauge to control the gap between the main traction roll...

Embodiment 2

[0059] see Figure 1-Figure 5 , the debugging process of disposable mask machine, including the following steps:

[0060] a. General assembly adjustment, the upper top surface of the ultrasonic welding head 1 is raised by 4mm relative to the supporting plate 2;

[0061] b. Adjust the pleat deflector 3, adjust the mutual positions of the 6 pleat deflectors 3, so that the width of the 3 layers of pleats is 9mm, and the 3 layers of pleats are connected at the first place in the width direction;

[0062] c. Wear the cloth and test the cloth running resistance at the pleat deflector 3, put the mask cloth roll on the material rack 4, the mask cloth passes through the pleat deflector 3, use a spring scale to pull the cloth, and test the cloth running resistance within 1Kg;

[0063] d. Adjust the stability of the automatic cloth running, the cloth passes through each roller in turn, adjust the main traction roller 5, use a feeler gauge to control the gap between the main traction rol...

Embodiment 3

[0074] see Figure 1-Figure 5 , the debugging process of disposable mask machine, including the following steps:

[0075] a. General assembly adjustment, the upper top surface of the ultrasonic welding head 1 is raised by 4mm relative to the supporting plate 2;

[0076] b. Adjust the pleat deflector 3, adjust the mutual positions of the 6 pleat deflectors 3, so that the width of the 3 layers of pleats is 10mm, and the 3 layers of pleats are connected at the first place in the width direction;

[0077] c. Wear the cloth and test the cloth running resistance at the pleat deflector 3, put the mask cloth roll on the material rack 4, the mask cloth passes through the pleat deflector 3, use a spring scale to pull the cloth, and test the cloth running resistance within 1Kg;

[0078] d. Adjust the stability of the automatic cloth running. The cloth passes through each roller in turn, adjust the main traction roller 5, use a feeler gauge to control the gap between the main traction ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com