Scale cleaning method for steam heating type cooking utensil

A technology for scale cleaning and cooking utensils, which is applied to cooking utensils, household utensils, kitchen utensils, etc., can solve the problems of difficult scale cleaning, low scale removal efficiency, waste of scale remover, etc. Scale removal efficiency and the effect of reducing scale residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

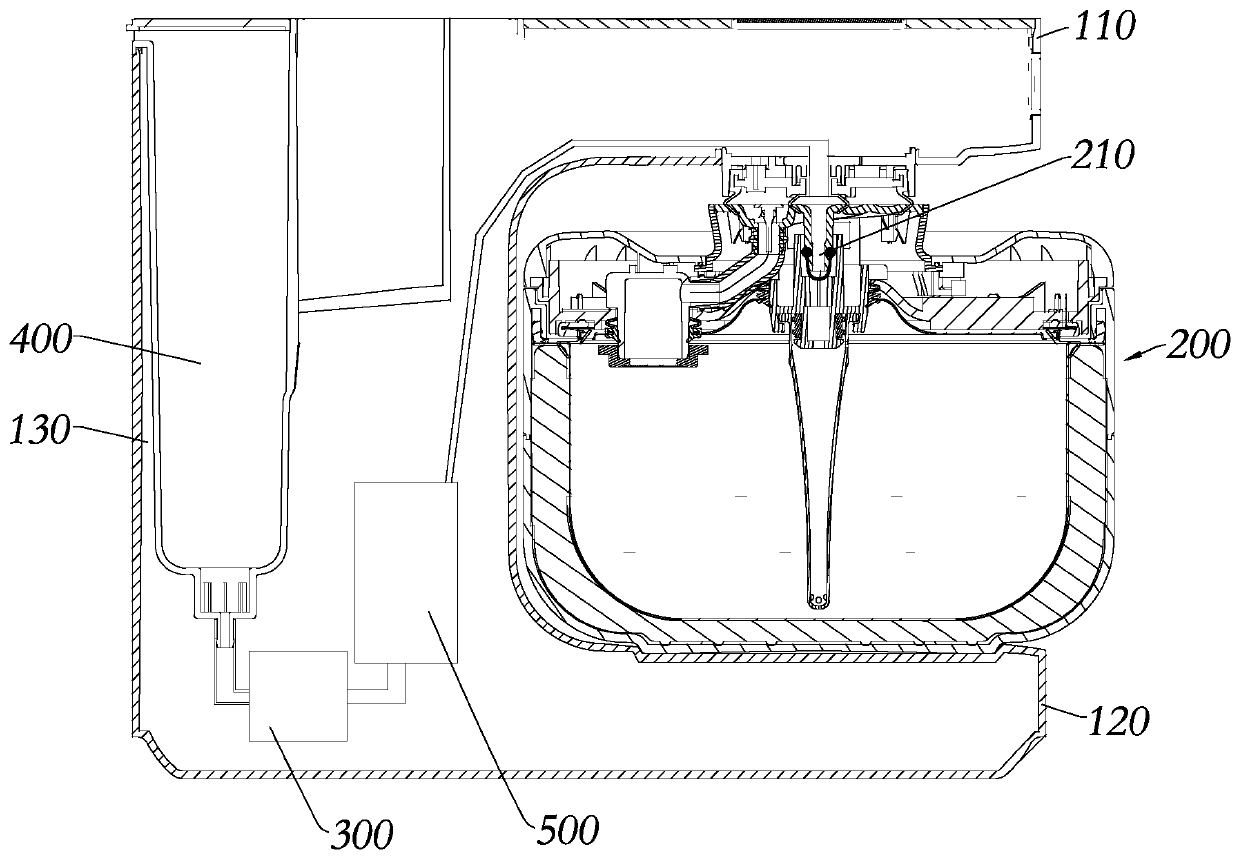

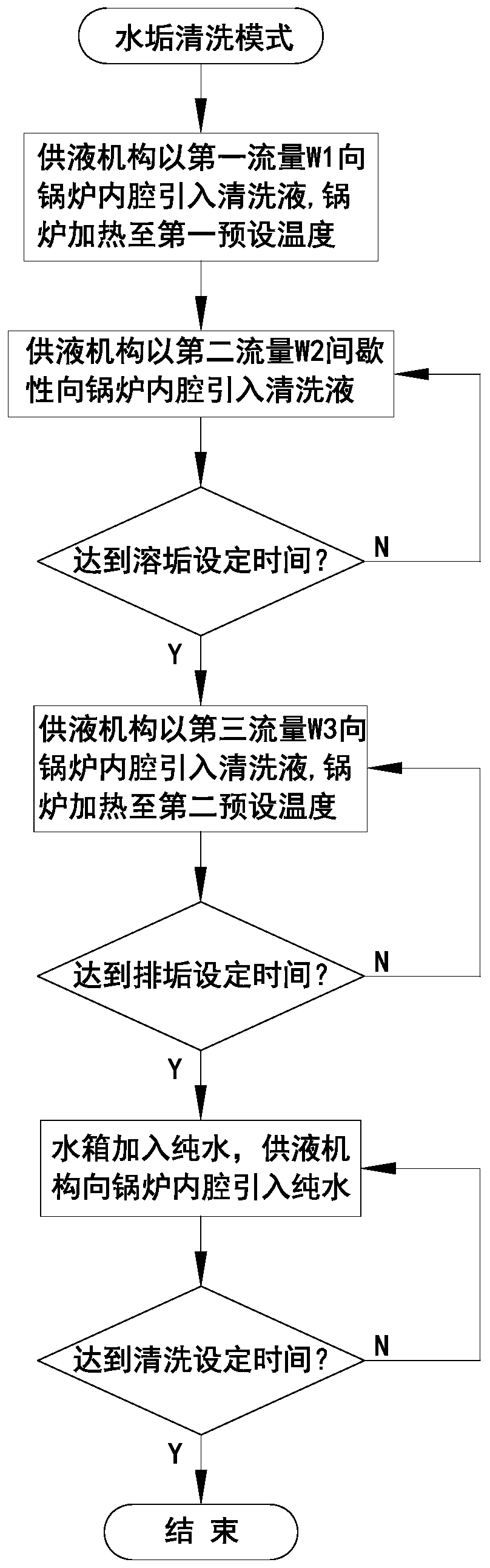

[0038] The present invention proposes a scale cleaning method for a steam heating cooking appliance, the steam heating cooking appliance includes: a steam generating part for heating water to generate steam and a liquid supply mechanism for supplying water to the steam generating part, the features of That is, the scale cleaning method includes the following steps: in the scale dissolution stage, the liquid supply mechanism introduces cleaning liquid into the inner cavity of the steam generating part, and the cleaning liquid dissolves the scale in the inner cavity of the steam generating part; The cleaning liquid is introduced, and the steam generating part is heated to vaporize part of the cleaning liquid, increasing the inner cavity pressure of the steam generating part, so that the dissolved scale is discharged out of the inner cavity of the steam generating part along with the cleaning liquid. The scale cleaning method proposed by the present invention adopts segmented clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com