Metal casting mold applied to composite liquid lift-up hard mold and based on low-pressure gravity casting

A metal casting and gravity technology, which is applied in the field of molds, can solve the problems of loss of quality of mold inner frame components, numerical deviation of storage liquid volume in the inner tank of finished products, and reduction of the use efficiency of formed metal objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

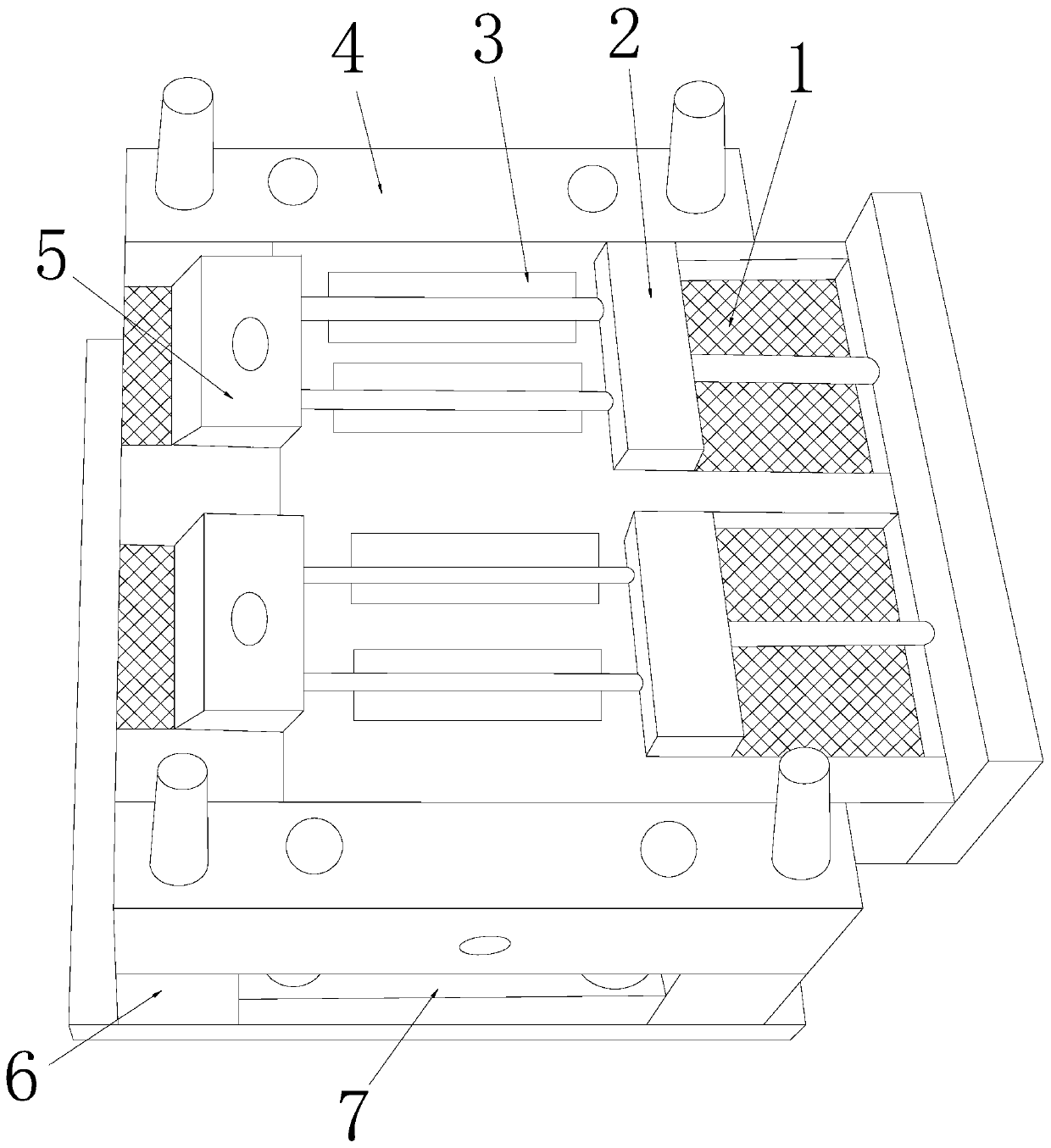

[0033] see Figure 1-Figure 6 , the present invention provides a metal casting mold based on low-pressure gravity pouring composite rising liquid hard mold. The liquid tank cylinder 5, the lower parting block 6, and the demoulding liner groove 7, the pouring liquid lifting tank 5 is inserted on the left side of the upper parting cover block 4 and the lower parting block 6 and are perpendicular to each other, The upper parting cover block 4 is mechanically connected with the lower parting seat block 6 through the mold release liner groove 7 and is on the same vertical plane, and the sliding backing plate 3 is closely attached to the front side of the upper parting cover block 4 , the filtrate scraping groove 1 is mechanically connected with the hydraulic linkage frame 2 and is on the same vertical plane, the filtrate scraping groove 1 is installed on the right side of the upper parting cover block 4, and the pouring liquid lifting groove cylinder 5 is set There are deep-diamet...

Embodiment 2

[0040] see Figure 1-Figure 6 , the present invention provides a metal casting mold based on low-pressure gravity pouring composite rising liquid hard mold, other aspects are the same as embodiment 1, the difference is:

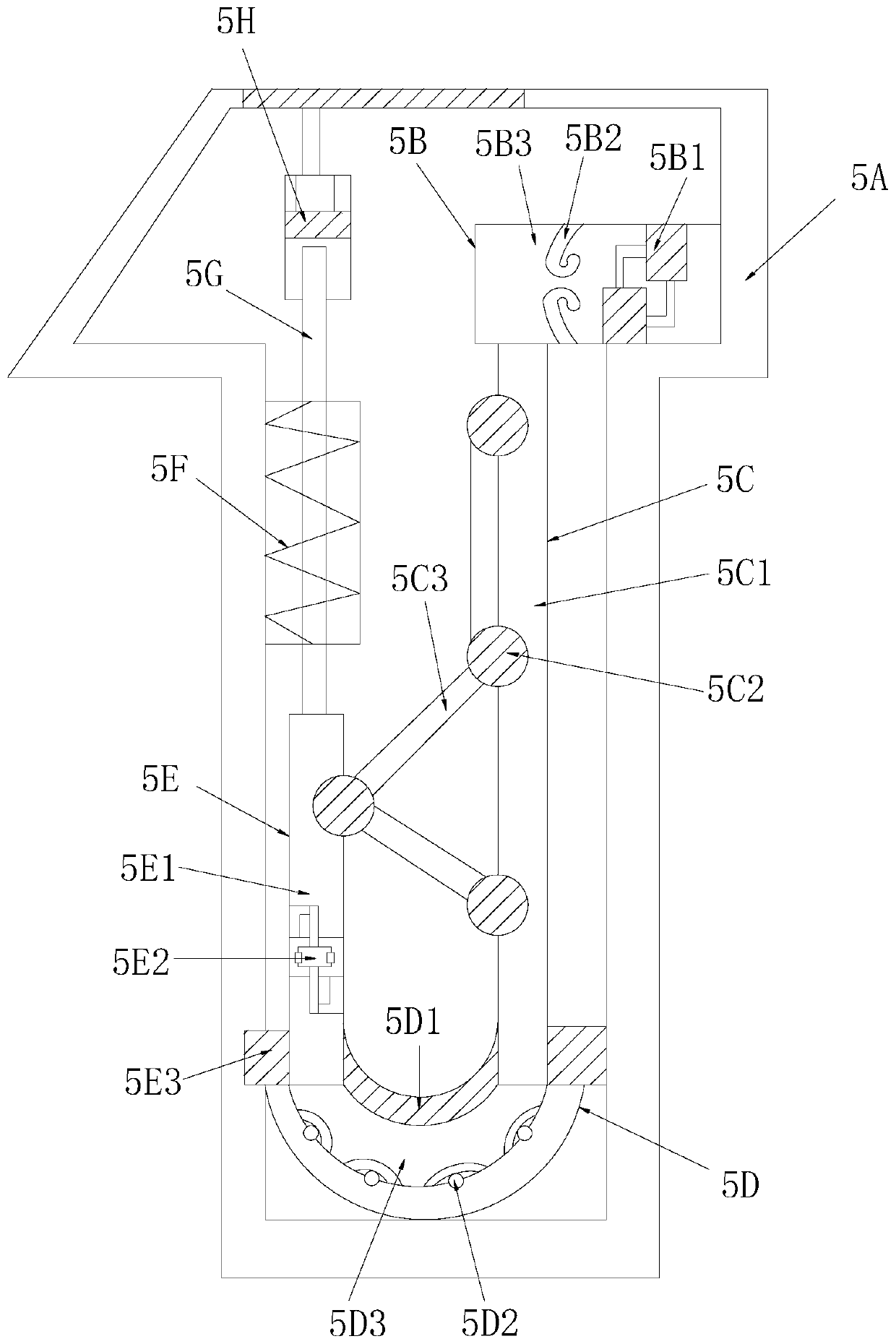

[0041] see figure 2 , the sprue vertical rod frame 5C is composed of a vertical rod through pipe 5C1, a sprue wheel valve port 5C2, and an inclined frame narrow channel 5C3, and the sprue wheel valve port 5C2 and the inclined frame narrow channel 5C3 are welded together and communicate with each other , the sprue wheel valve port 5C2 is nested on the left side of the vertical rod through pipe 5C1 and is on the same vertical plane, through the sprue wheel valve port 5C2 and the inclined frame narrow channel 5C3 oblique cross communication, ensuring the cobweb type low position Mold upwelling casting operation effect.

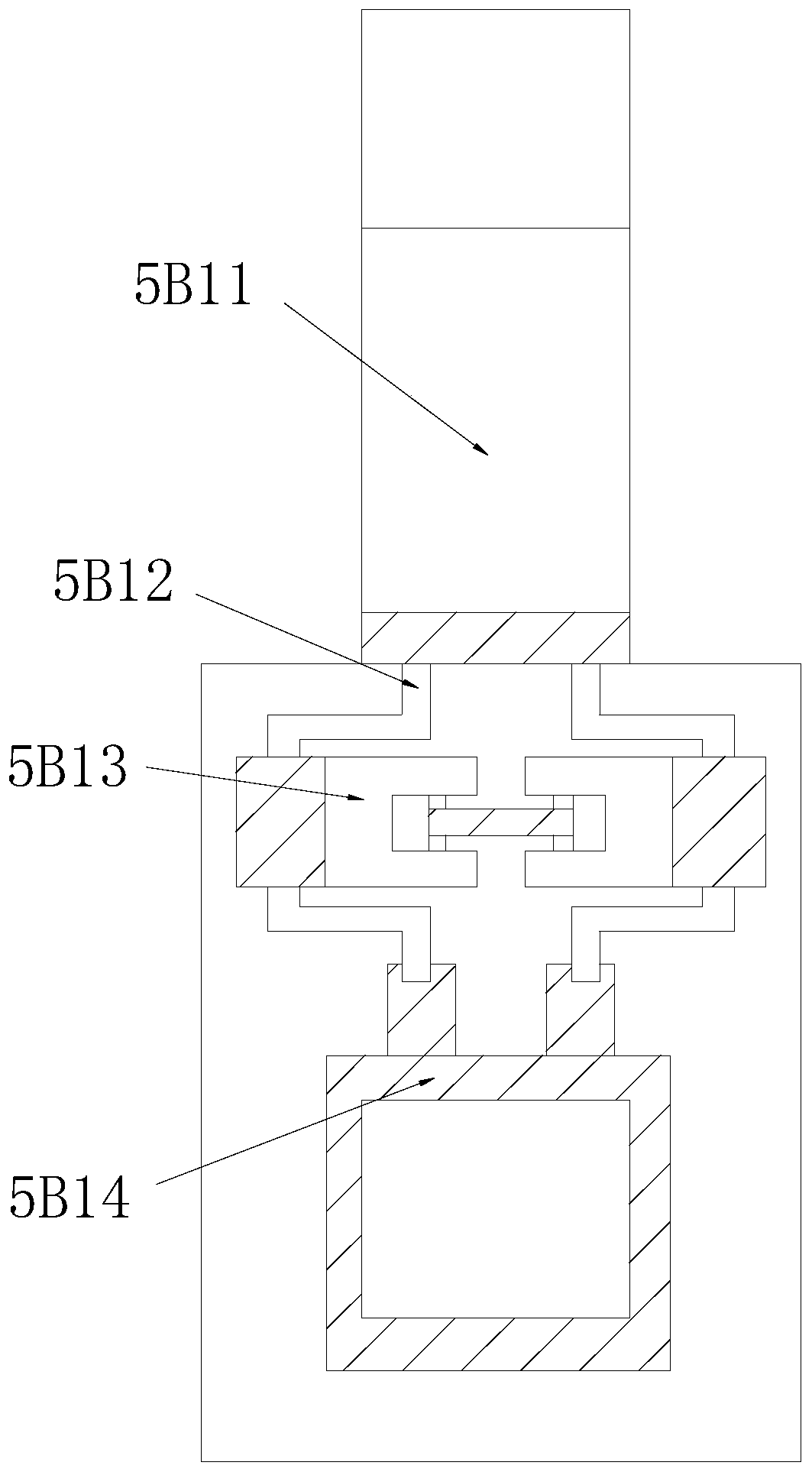

[0042] see Figure 4 The sprue wheel valve port 5C2 is composed of a bushing roller bar 5C21, a propeller blade 5C22, a wheel groove body 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com