Yarn winding forming machine and method

A winding forming and yarn technology, applied in the field of yarn production, can solve the problems that affect the quality of yarn use and forming, affect the quality of formed yarn rolls, and the yarn is prone to scatter, so as to expand the scope of application and utilization. The effect of reducing the surface hair fork phenomenon and improving the quality of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

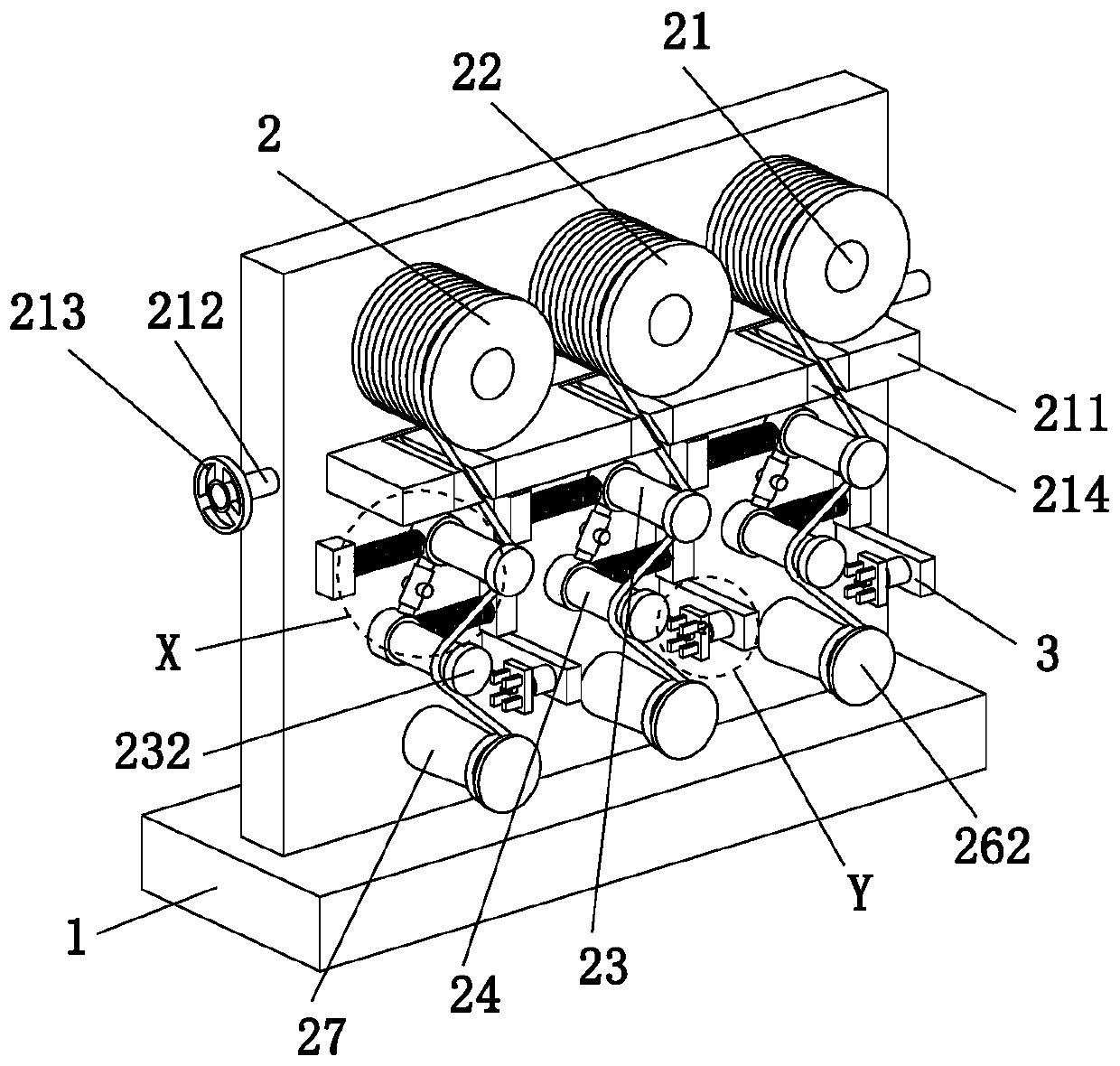

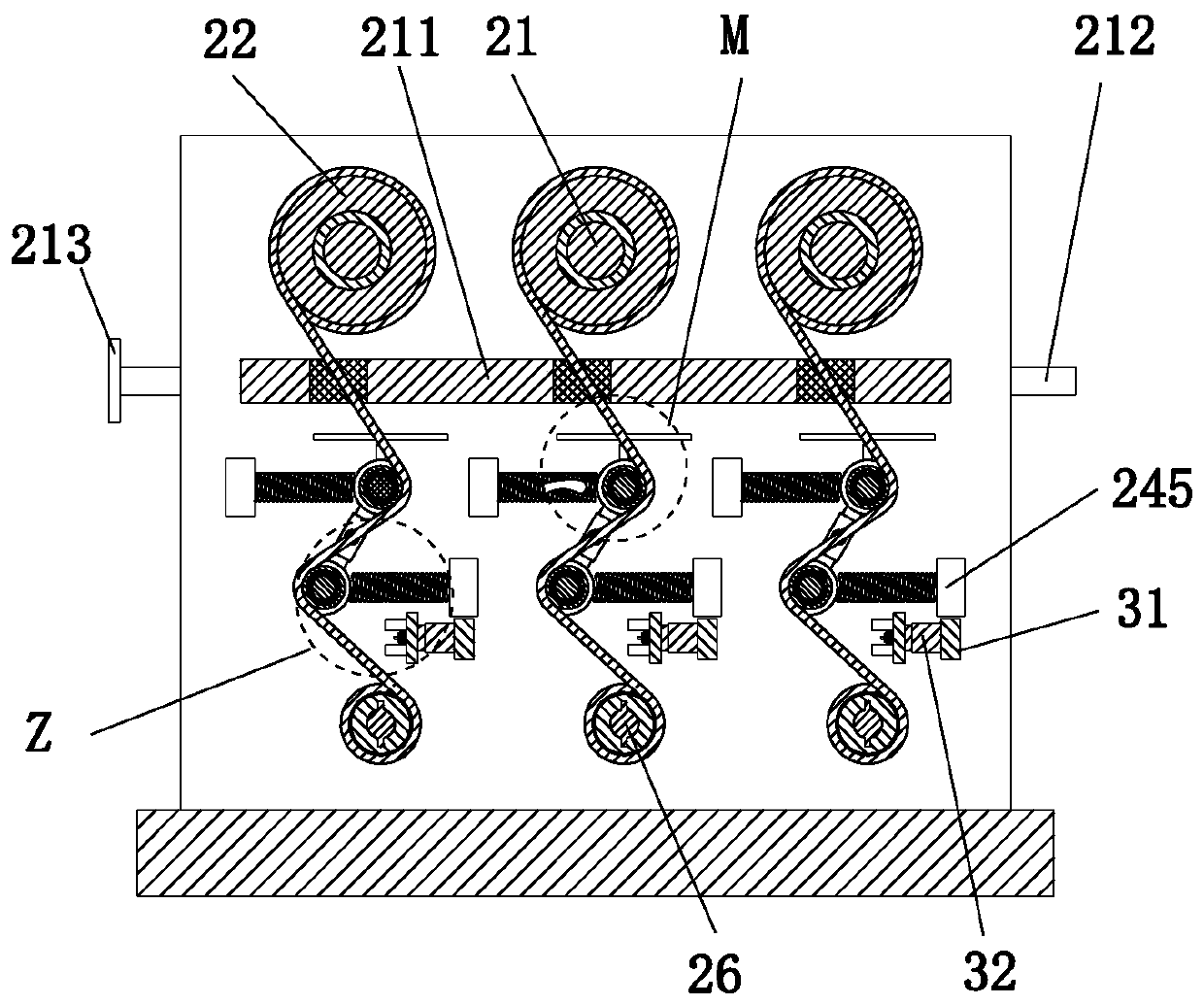

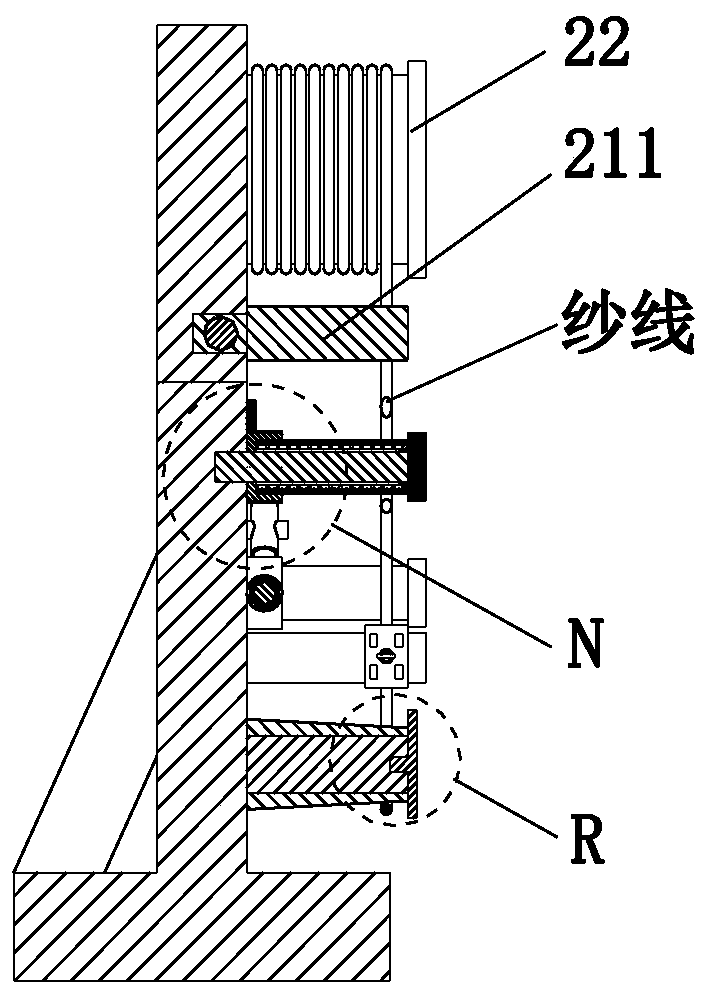

[0037] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 10 , to further elaborate the present invention.

[0038] A yarn winding and forming machine, comprising a ground vertical frame 1, a winding device 2 and a cutting device 3, the front end of the ground vertical frame 1 is equipped with a winding device 2 equidistant from left to right, the ground The lower end of the front end face of the vertical frame 1 is equidistantly equipped with a cutting device 3 from left to right, and the cutting device 3 is located on the right side of the winding device 2 .

[0039] The winding device 2 includes a rotating shaft 21, a former bobbin 22, a first rotating shaft 23, a second rotating shaft 24, a ring 25, a fixed shaft 26, a tapered bobbin 27 and a transmission group 28, and the rotating shaft 21 is passed through a sliding The fitting method is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com