Heat treatment process of long shaft

A heat treatment device and long shaft technology, applied in the field of heat treatment, can solve the problems of bar surface damage, hard collision, etc., and achieve the effect of enhancing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below with reference to the accompanying drawings.

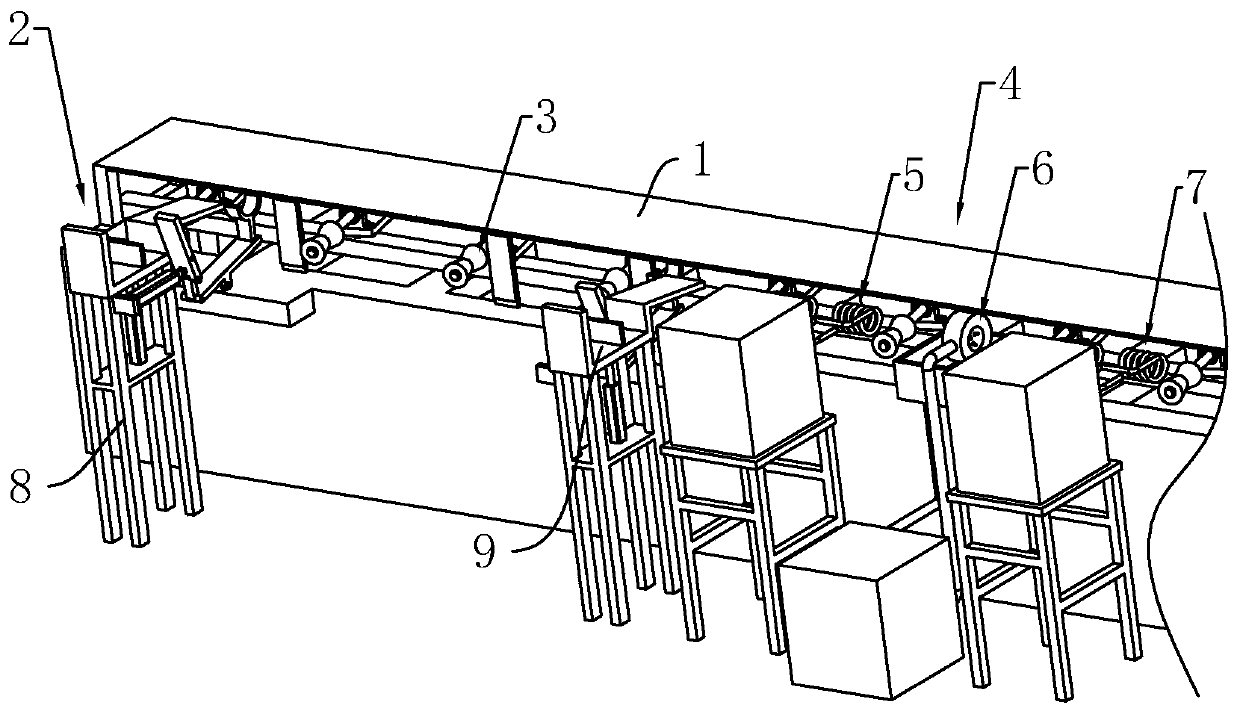

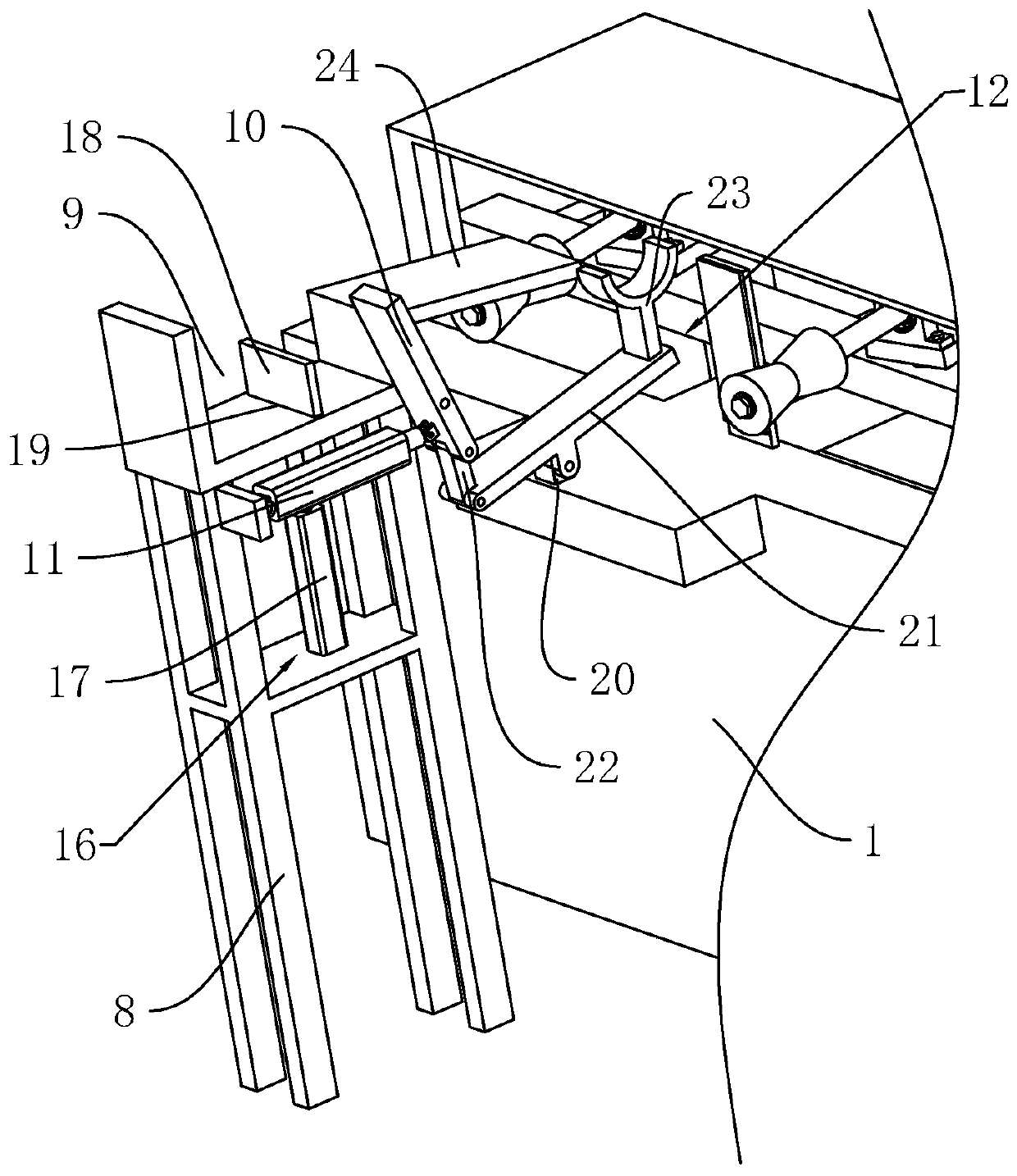

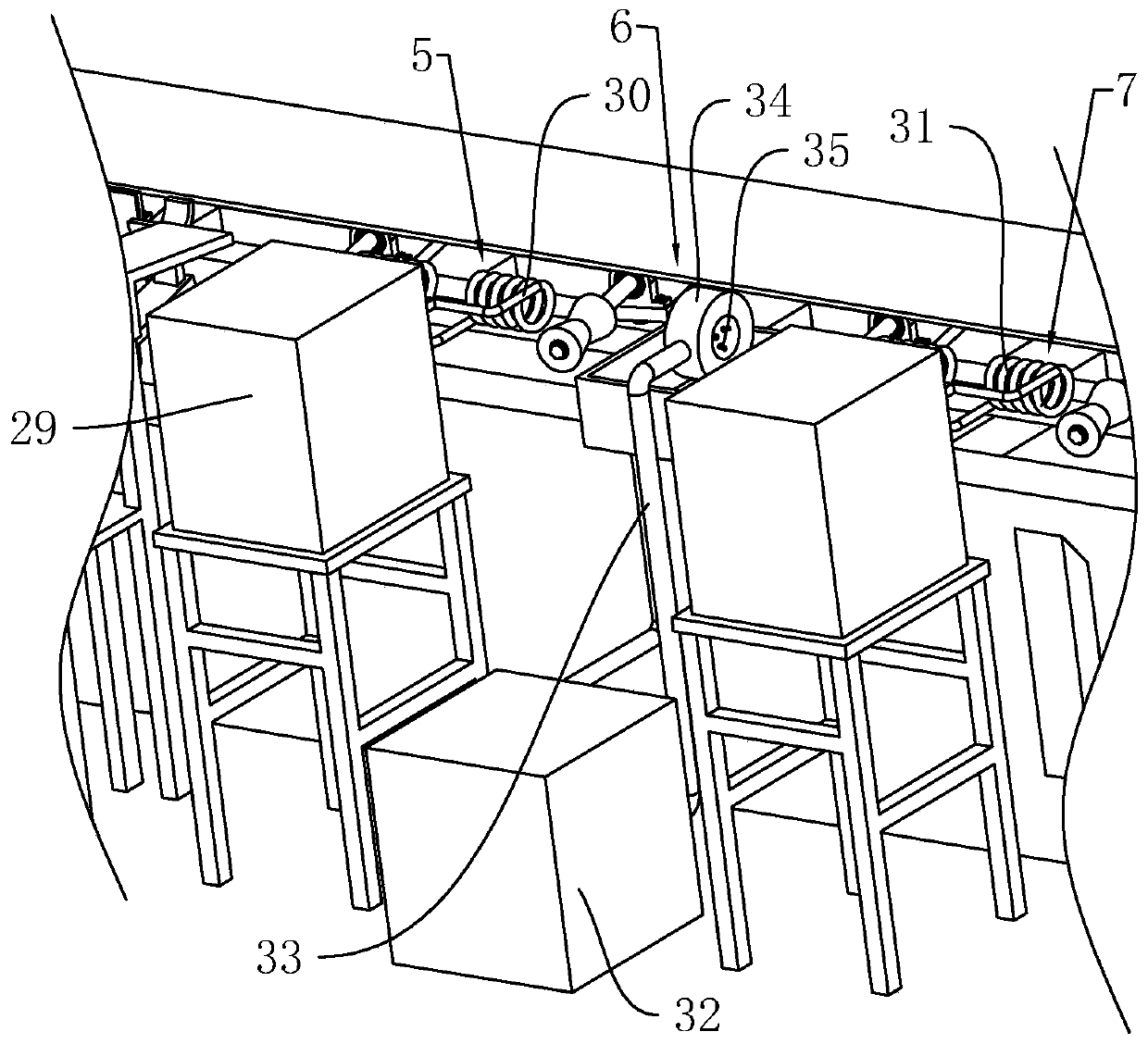

[0041] refer to figure 1 , which is a heat treatment process for a long shaft disclosed in the present invention, comprising the following steps: step S1, selecting a heat treatment device, and feeding the long shaft to the heat treatment device; step S2, quenching, and the quenching temperature is 830 ℃-850 ℃; step S3 , cooling, the long shaft is cooled by spraying, and the cooling temperature is 24 ℃-26 ℃; step S4, tempering, the tempering temperature is divided into a first-stage tempering and a second-stage tempering, and the first-stage tempering temperature is 710 ℃-750 ℃, the second-stage tempering temperature is 500 ℃-600 ℃; step S5, blanking; and the conveying speed of the long axis in steps S2-S4 is 400 mm / min-600 mm / min.

[0042] After the long-axis bar is loaded, it is first quenched, and the quenching temperature is 830°C-850°C, and then it quickl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com