Single-guide-rail automobile glass lifting and lowering device of brand-new structure form

A structural form and technology of automotive glass, applied in building structure, power control mechanism, wing fan control mechanism, etc., can solve the problems of labor-intensive assembly, increase manufacturing cost, quality cost, reduce production takt, etc., and achieve economical savings. Purchasing costs and manufacturing costs, ensuring product quality stability, and improving the effect of production rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further elaborate the technical means and effects that the present invention takes to achieve the above-mentioned purpose, the specific implementation, structure, characteristics and effects of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments. It should be understood that the present invention The specific embodiments described are only used to explain the present invention, not to limit the present invention.

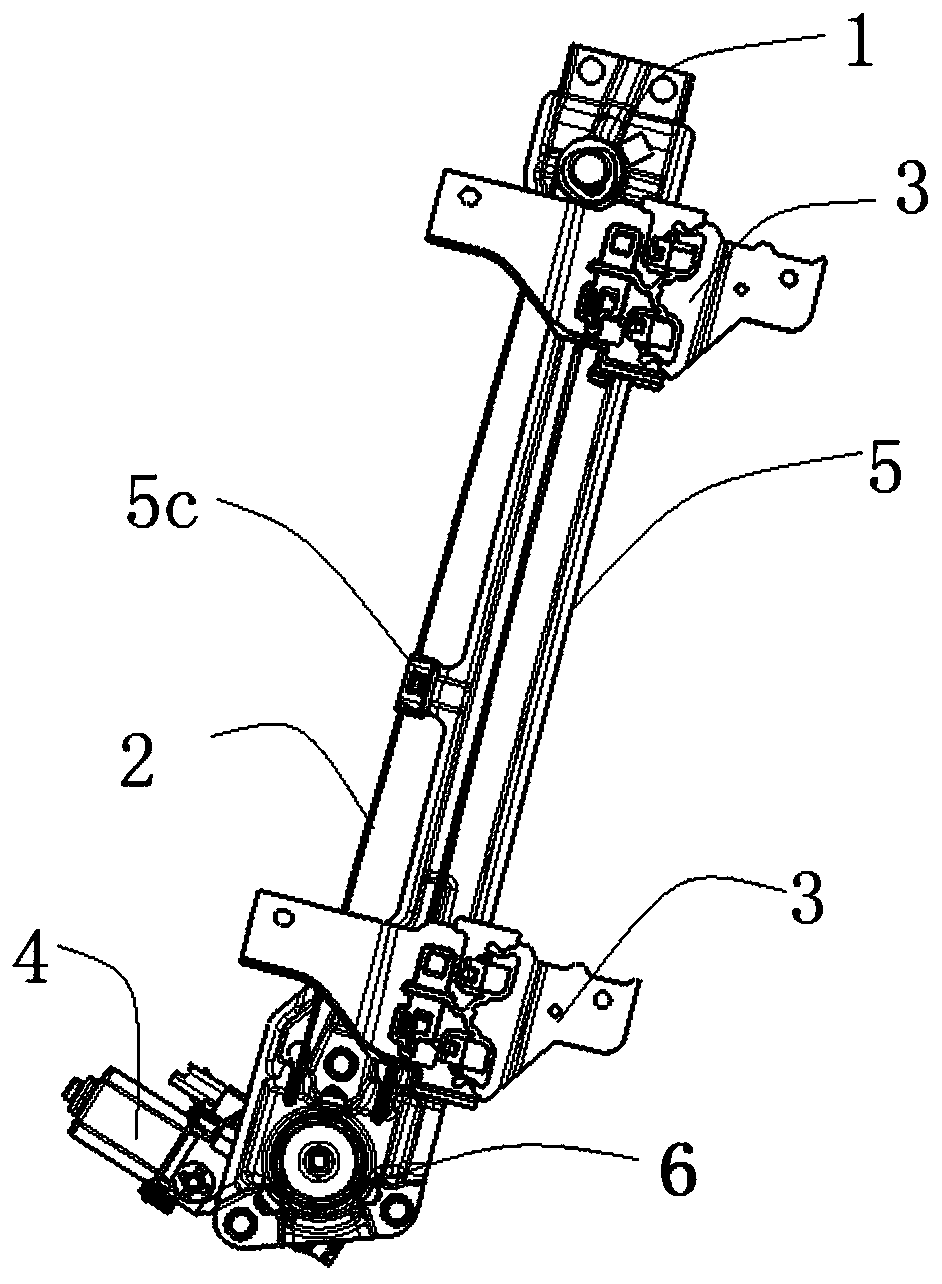

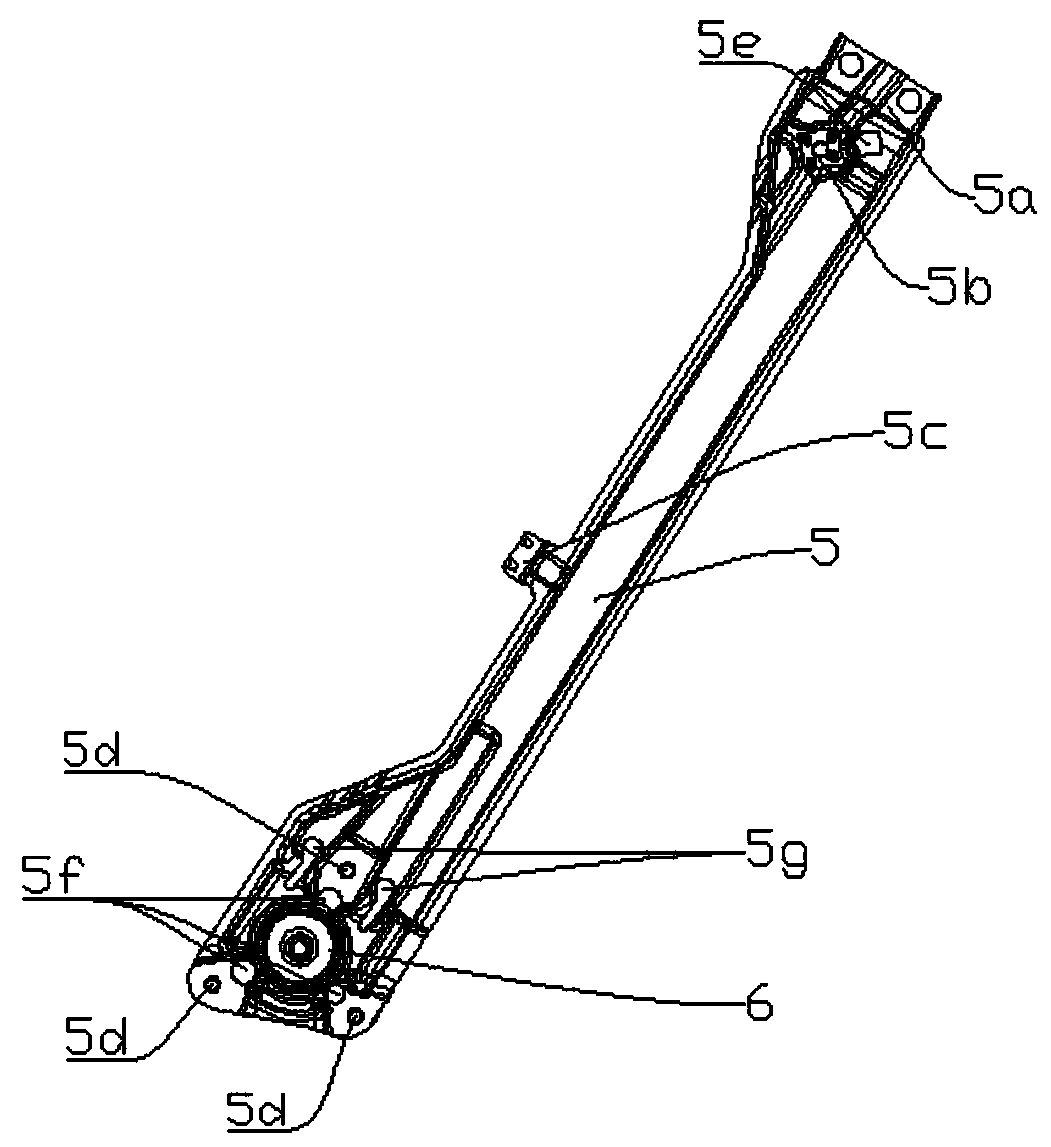

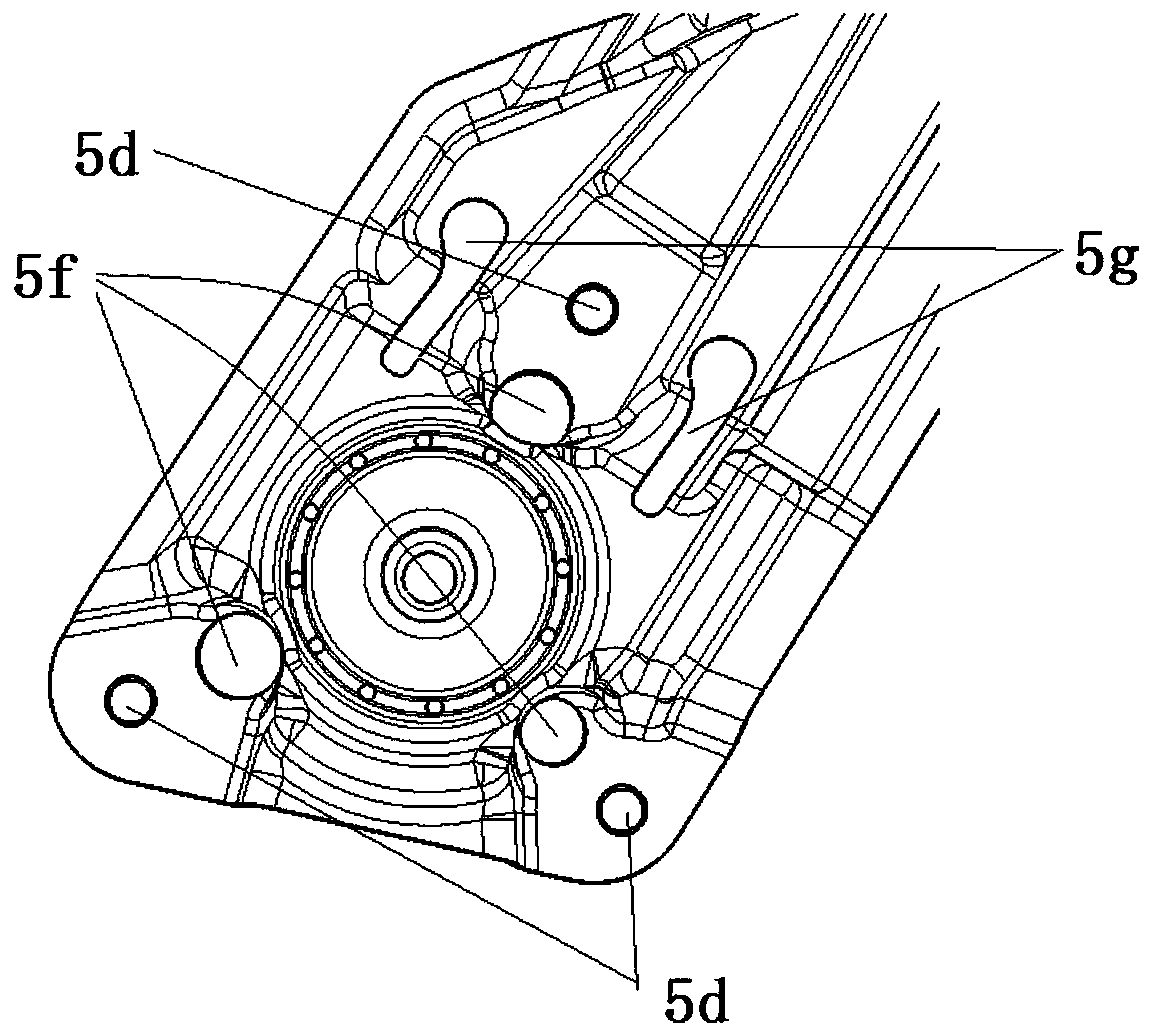

[0024] Please check Figure 1 to Figure 5 As shown, the present invention provides a single-rail automotive window regulator with a new structural form, including a winding wheel 6, a guide wheel 1, upper and lower wire ropes 2 wound on the winding wheel 6 and the guide wheel 1, and a sliding connection The slider 3 of the upper and lower steel wire ropes 2 and the output motor 4 for driving the reel 6 to rotate also includes an integrated stamping guide rail 5, and the integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com