Integrally well forming type shaft tunneling machine

A roadheader and integrated technology, which is applied to shaft equipment, well sinking, shaft lining, etc., can solve the problems of slow excavation speed and inconvenient disassembly and assembly of equipment, and achieve fast disassembly and assembly, fast construction efficiency, and reduced construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

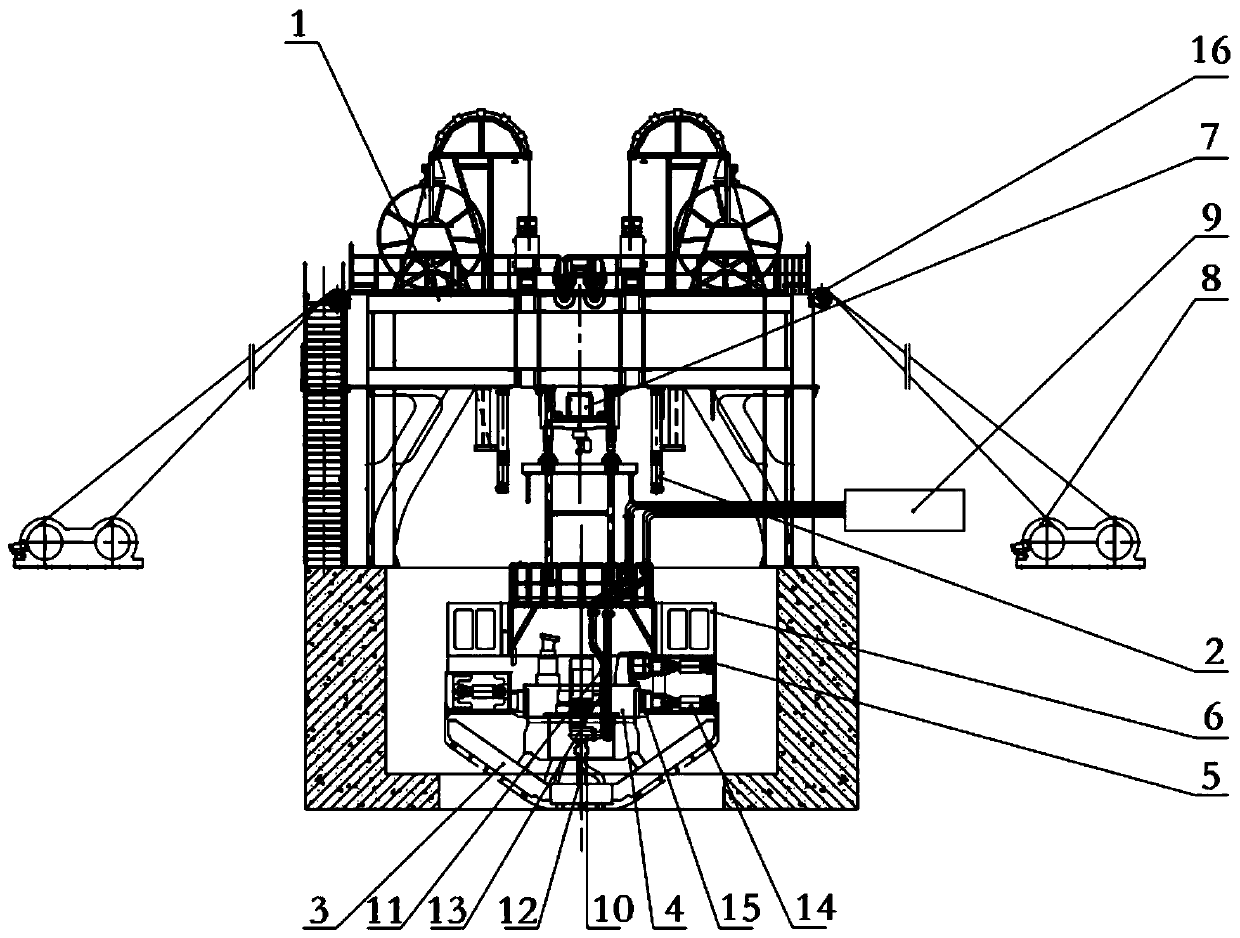

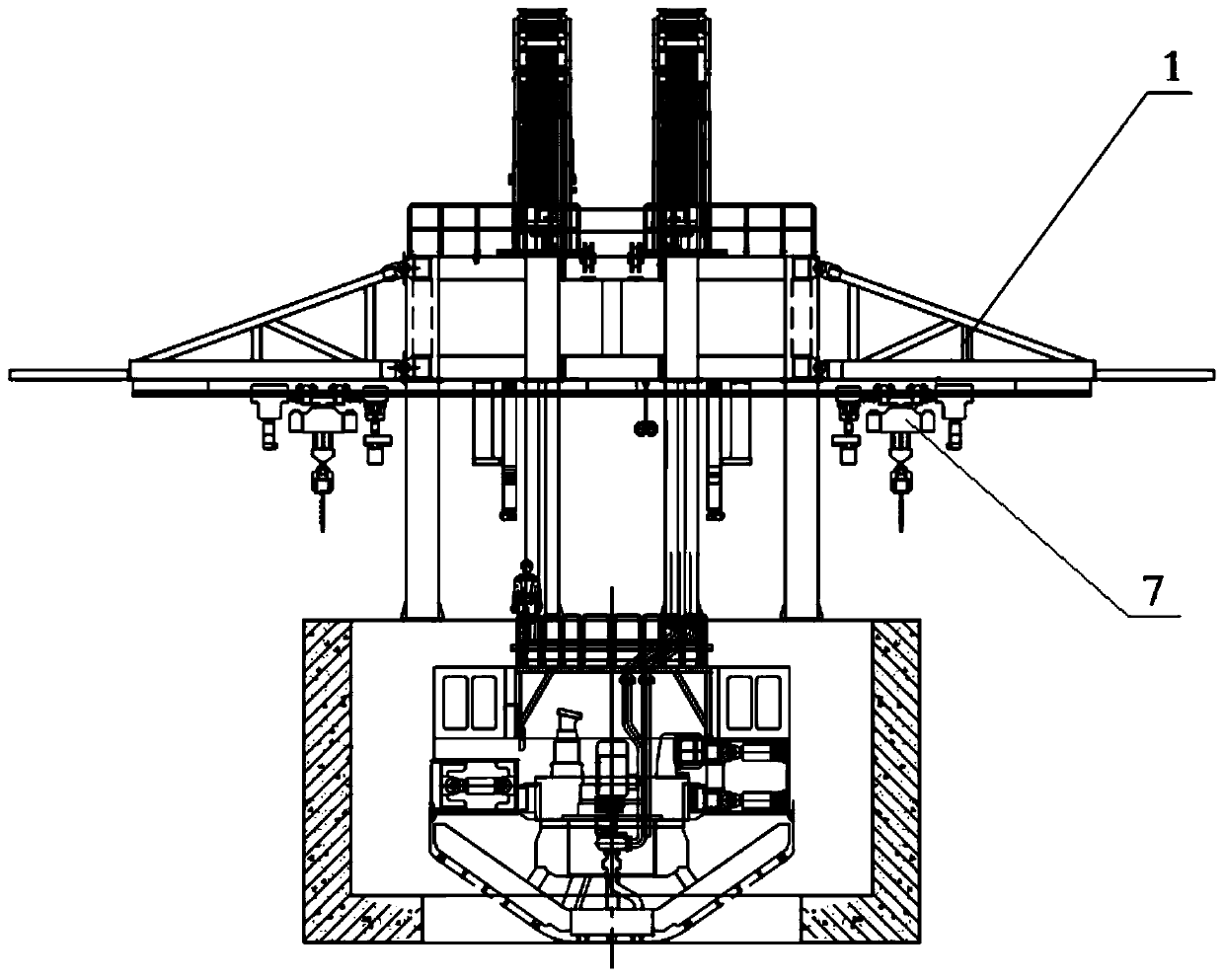

[0028] see Figure 1 ~ Figure 3 , a kind of integrated well-type shaft boring machine includes above-ground equipment fixed on the ground and an in-hole main engine driven under the ground; the above-ground equipment includes a supporting structure frame 1, a propulsion system 2 and a main engine lifting system 8; the supporting structure frame 1 is fixed On the ground level; the propulsion system 2 is installed on the supporting structure frame 1; the main engine lifting system 8 is fixed on the ground, the supporting structure frame 1 is provided with a guide pulley block 16, and the free end of the steel strand in the main engine lifting system 8 passes through Through the guide pulley block 16, it is used to hoist the main engine in the well.

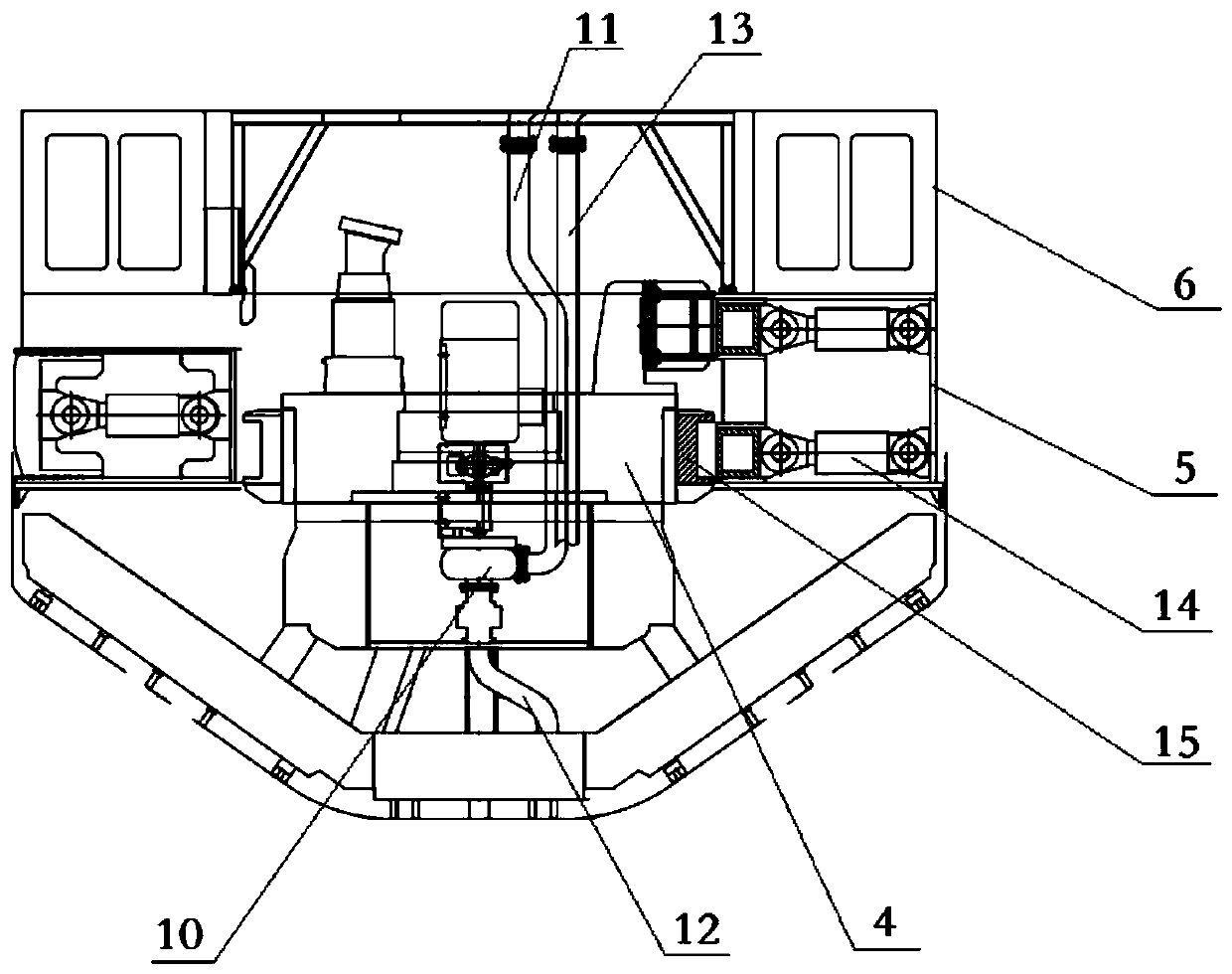

[0029] The main machine in the well includes a cutter head 3, a main drive 4, a steel pipe ring 5 and a support unit; the support unit in this embodiment is preferably a steel pipe sheet; as image 3 As shown, the flange on the cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com