Waste heat recovery and demisting system and method for exhaust steam and continuous sewage of garbage power station

A waste heat recovery and power station technology, applied in heat recovery systems, chemical instruments and methods, separation methods, etc., can solve the problems of water and heat loss, white smoke and other problems in the thermal system of power stations, and reduce the loss of soda and heat. , the effect of beautifying the production environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

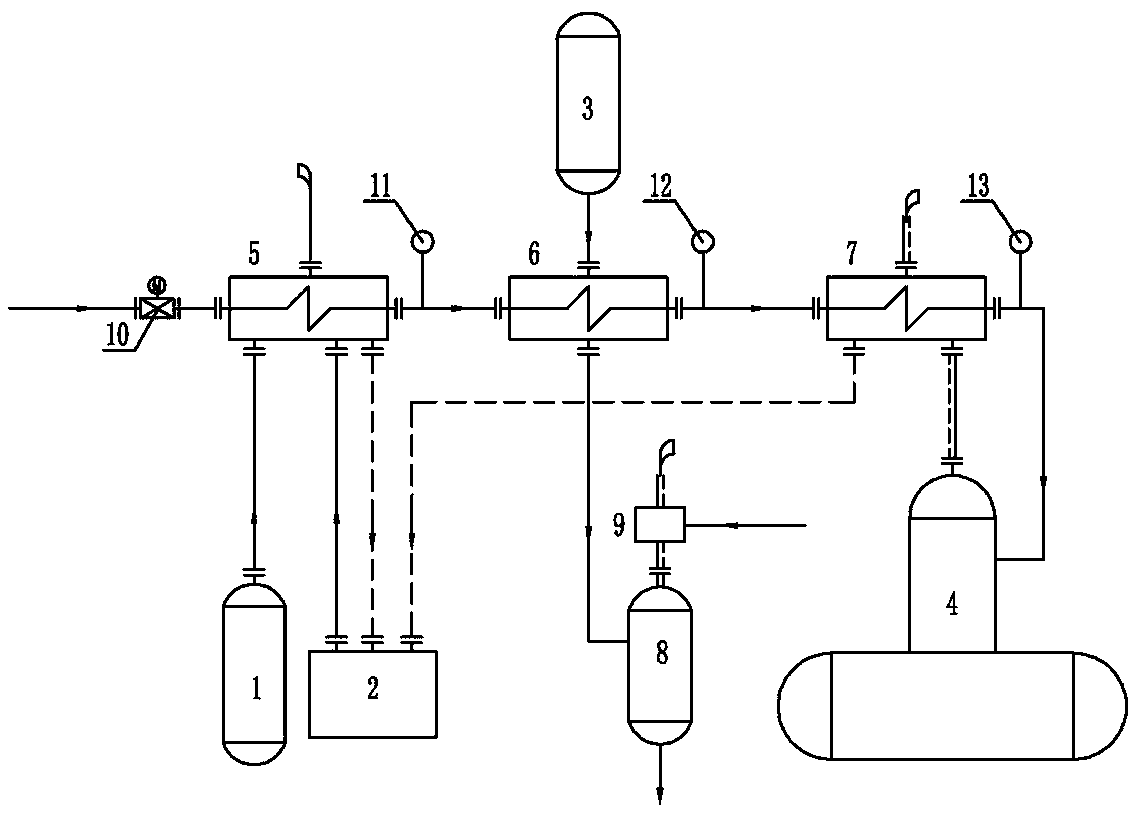

[0012] see figure 1 , the embodiment of the present invention includes a hydrophobic expansion vessel 1, a hydrophobic tank 2, a continuous blowdown expansion vessel 3, a deaerator 4, a first-stage heat exchanger 5, a second-stage heat exchanger 6, a third-stage heat exchanger 7, Periodic sewage expansion vessel 8, exhaust steam eliminator 9, regulating valve group 10, No. 1 temperature measuring device 11, No. 2 temperature measuring device 12, No. 3 temperature measuring device 13 and water inlet pipeline.

[0013] The first-stage heat exchanger 5, the second-stage heat exchanger 6, and the third-stage heat exchanger 7 all adopt surface heat exchangers, the cooling water is on the tube side, and the steam is on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com