An intelligent electro-friction carbon composite material and its manufacturing method and service monitoring method

A technology of carbon composite materials and smart electricity, which is applied in the direction of carbon preparation/purification, measuring devices, and measurement of electrical variables, which can solve the problems of difficult monitoring of electrical carbon composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

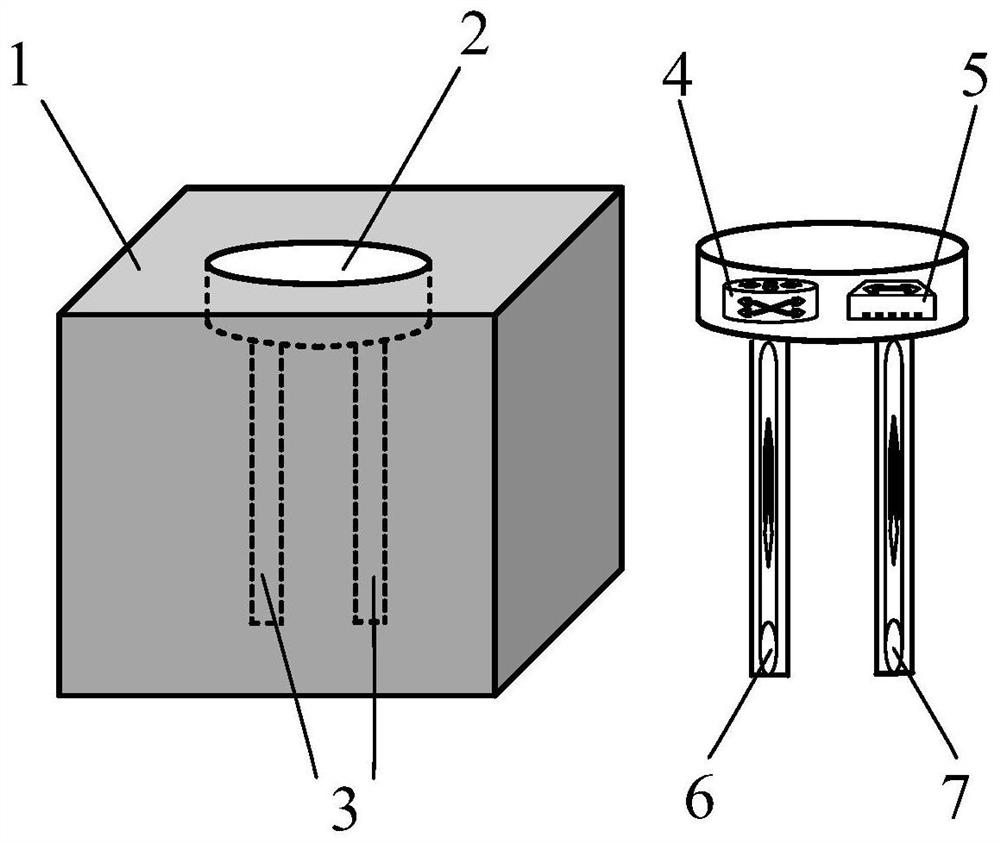

[0039] Such as figure 1 As shown, the present invention provides an intelligent electric friction carbon composite material, including a material main body 1 and an intelligent structure embedded in the material main body 1; In the elongated hole 3, a launcher 4 and a power supply unit 5 connected to the launcher 4 are placed in the cylindrical through groove 2; stress sensors connected to the launcher 4 and the power supply unit 5 are inserted in the two elongated holes 3 6 and voltage sensor 7.

[0040] In this embodiment, the diameter of the cylindrical through groove 2 is greater than 1 / 3 of the diameter of the material main body 1, and the height of the cylindrical through groove 2 is 1 / 10 of the height of the material main body 1, and the diameter of the two elongated holes 3 is 1 / 10 of the material main body 1. 1 / 10 of the length of the main body 1.

[0041] In this embodiment, the material body 1 is made of carbon-copper composite material; the intelligent structure ...

Embodiment 2

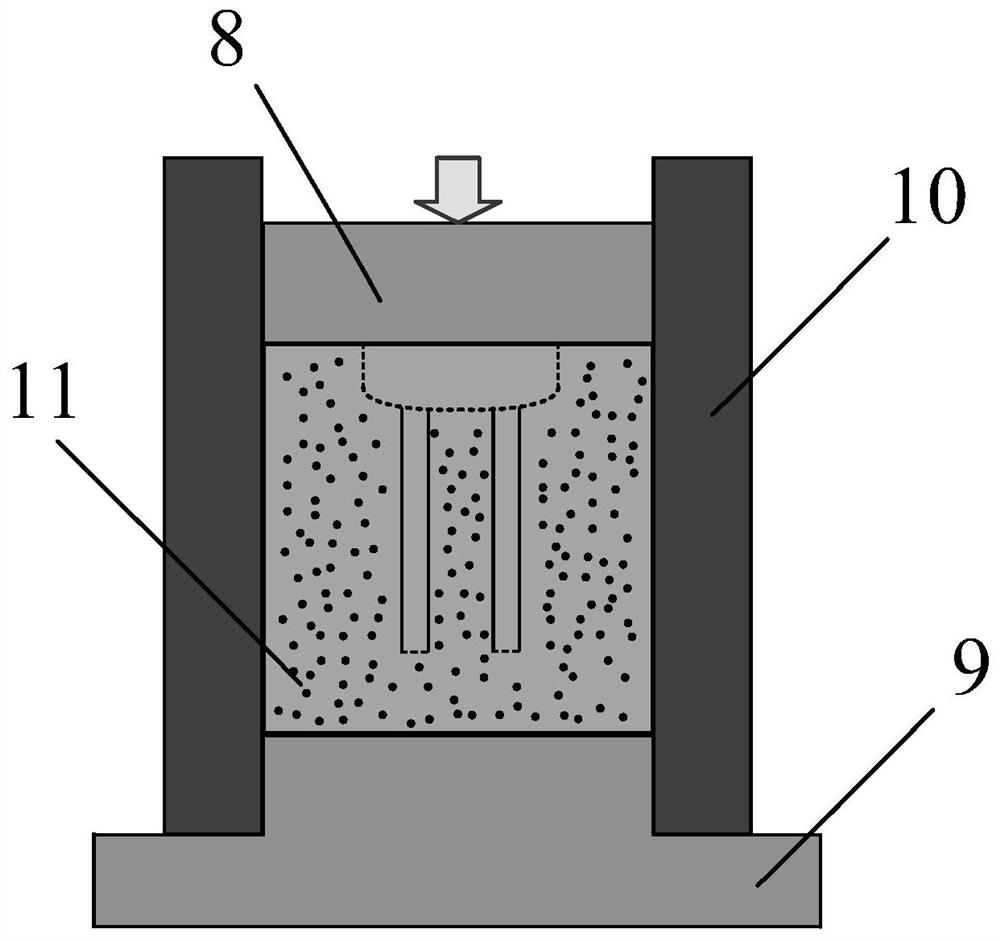

[0051] Such as Figure 3-Figure 4 As shown, the present invention also provides a method for manufacturing an intelligent electric friction carbon composite material. An intelligent structural mold is built in the pressurized mold. The production process is as follows:

[0052] S1. Making a smart structure of carbon fiber reinforced thermoplastic composite material, and embedding stress sensors, voltage sensors, transmitters and power supply units into the smart structure;

[0053] S2, select pitch coke, petroleum coke, natural graphite powder and copper powder raw materials, and mix uniformly, make powdery mixture, wherein, pitch coke powder 40-60 parts, petroleum coke powder 20-30 parts, natural graphite powder 10- 20 parts, copper powder 60-80 parts;

[0054] S3. Put the powdery mixture into the pressurized mold, fix the lower die punch and the female die, and press down the upper die punch by 250-300MPa, transfer the pressure to the powdery mixture through the upper die p...

Embodiment 3

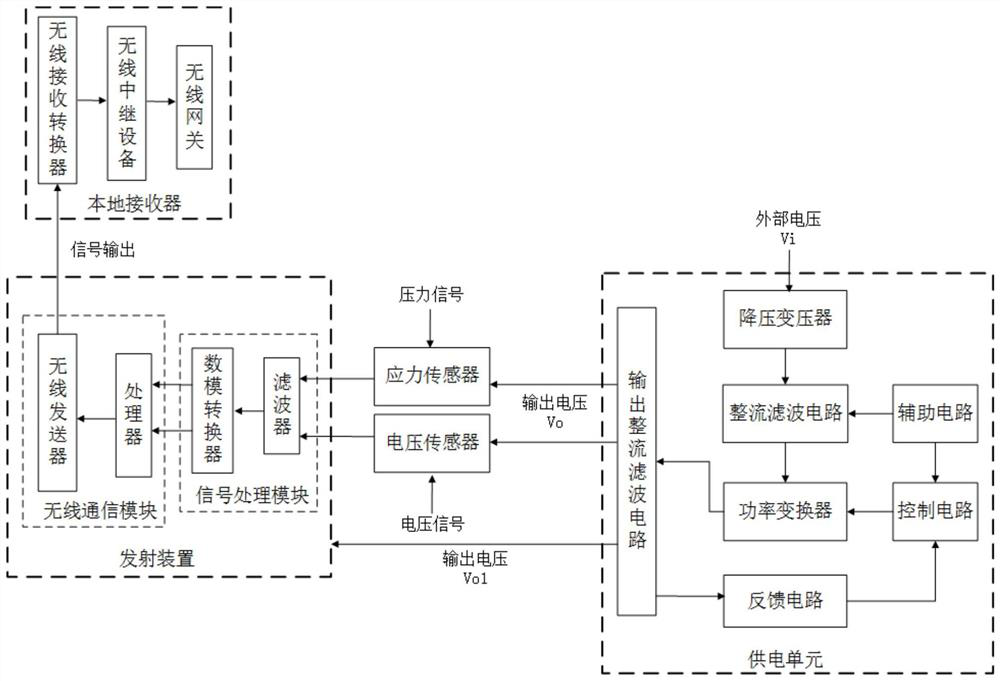

[0060] Such as Figure 5 As shown, the present invention also provides a service monitoring method of an intelligent electric friction carbon composite material, comprising the following steps:

[0061] A1. Use the power supply unit to convert the external electric energy, and supply the converted electric energy to the stress sensor, the voltage sensor and the transmitting device respectively;

[0062] A2. Use the stress sensor to collect the pressure signal of the intelligent electric friction carbon composite material, use the voltage sensor to collect the voltage signal at both ends of the intelligent electric friction carbon composite material, and transmit the collected pressure signal and voltage signal to the transmitting device;

[0063] A3. Use the transmitting device to convert the pressure signal and voltage signal into digital pressure detection signal and voltage detection signal, and send the converted signal to the local receiver for data processing, so as to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com