Constant-power control system of hot sawing machine

A constant power control and control system technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as load power changes, equipment damage, uneven mass distribution, etc., to improve service life and production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The constant power control system of the hot saw machine of the present invention will be further described in detail below in conjunction with the accompanying drawings.

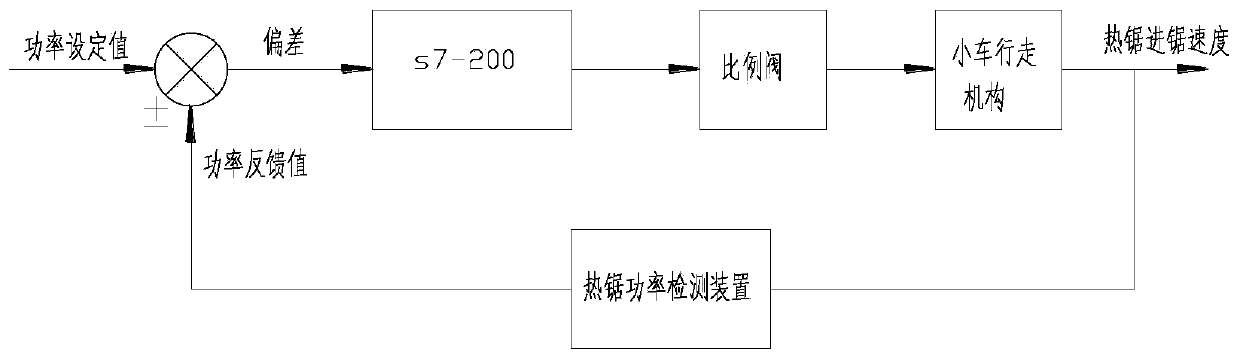

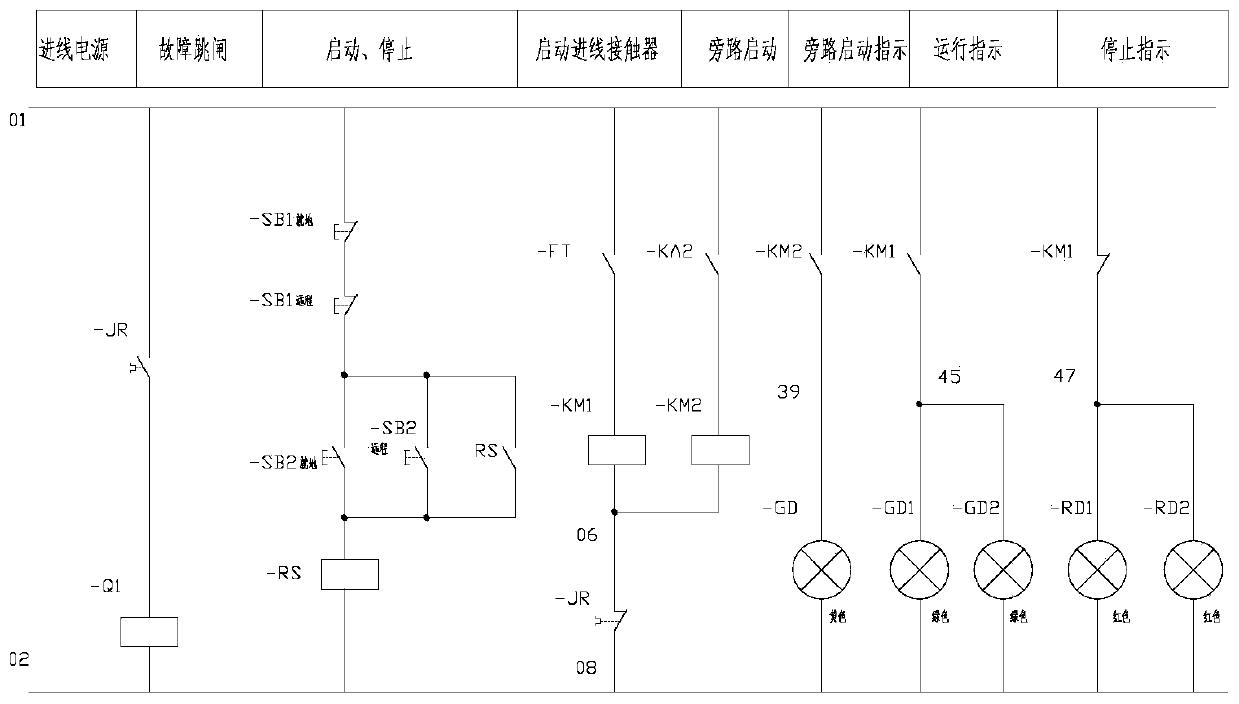

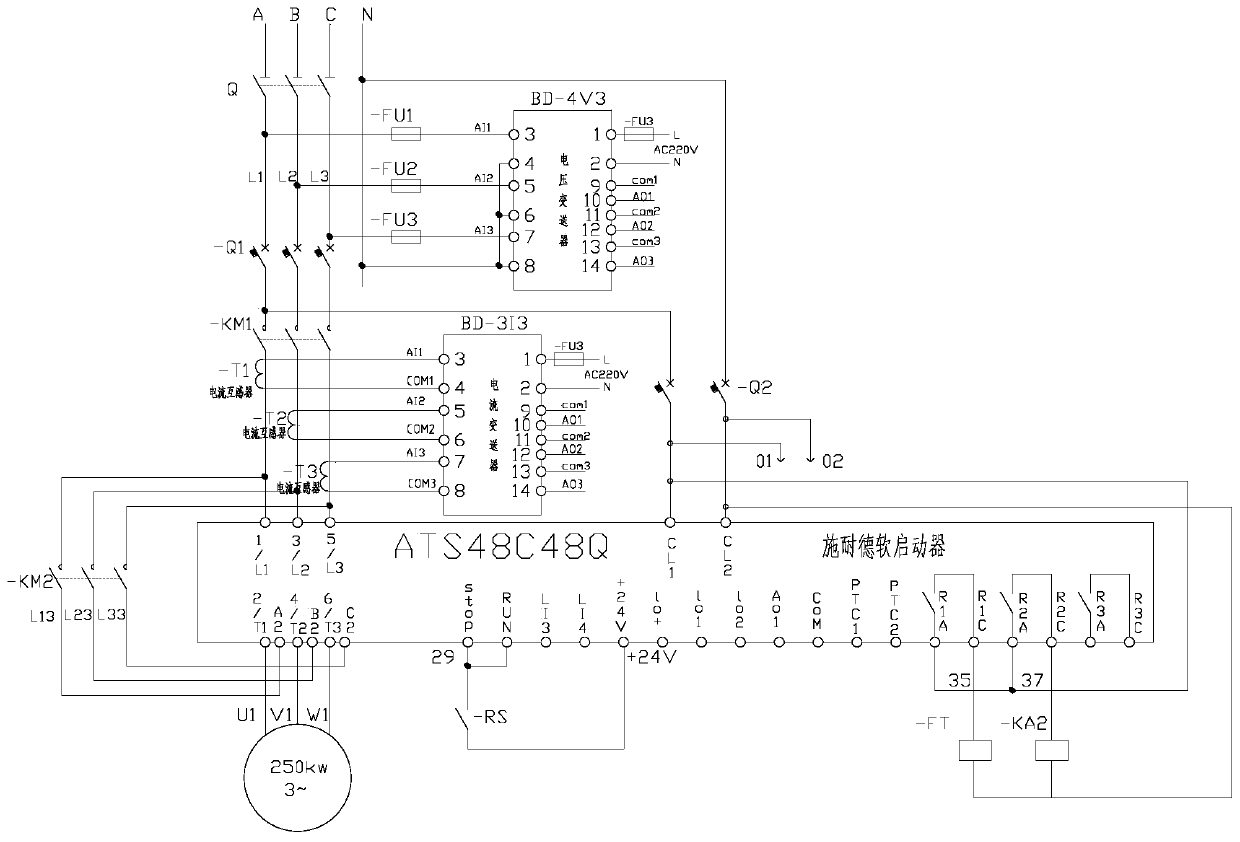

[0014] Such as Figure 1 to Figure 4 Shown is a schematic diagram of the work flow and a schematic diagram of the control system of the constant power control system of the hot saw machine of the present invention.

[0015] figure 1 It is a schematic diagram of the working process of the constant power control system of the hot saw machine. The constant power control system of hot saw machine is a closed-loop automatic control system. The system takes Siemens S7-200PLC controller as the core, and the power setting value manually input and the actual running power of the motor detected by the current and voltage transmitter For comparison, the output deviation control amount is sent to the proportional valve of the hydraulic cylinder of the feed saw control system to control the size of its opening,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com