Intelligent railway freight assembling method

A technology of railway freight and assembly methods, which is applied in the field of logistics and freight transportation, can solve the problems of unsatisfactory space utilization of boxcars and neglect of the practicality of loading and stowage, and achieve the effects of improving stowage efficiency, loading rate, and transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

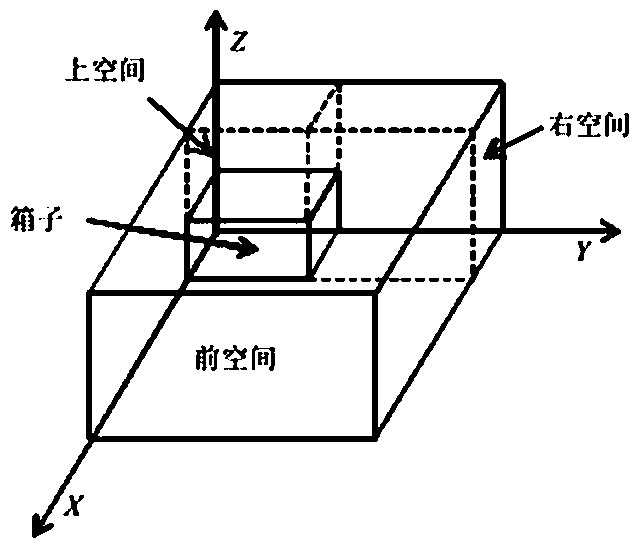

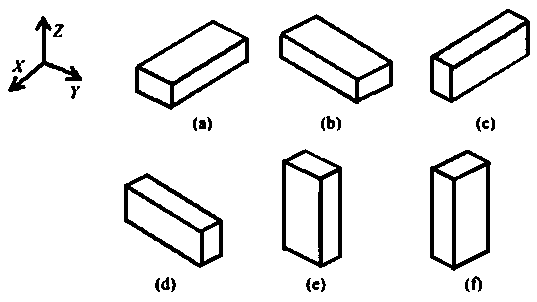

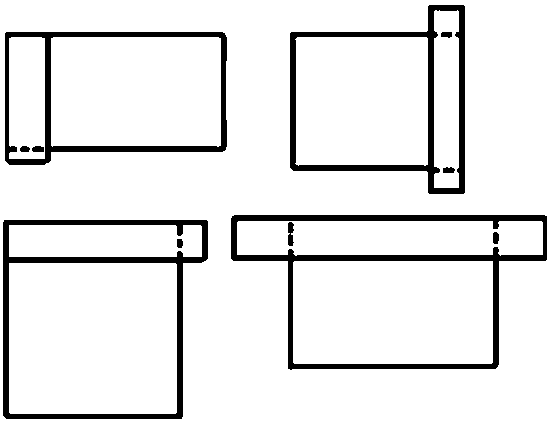

[0029] Embodiment: The railway freight intelligent stowage method in this embodiment is used to provide an optimized cargo stowage scheme under the conditions of corresponding transport vehicle volume and vehicle weight, thereby improving economy and practicability. Since the goods have packing boxes during transportation, the goods in this embodiment are based on the goods packed in the rectangular parallelepiped packing box, that is, the space occupied by the goods loaded on the transport vehicle is based on the size of the rectangular parallelepiped packing box ; And for transport vehicles, the present embodiment takes boxcars as an example.

[0030] Specifically, first of all, the loading and distribution problem is a "size coordination" problem, which involves space utilization. This embodiment aims to solve how to improve the space utilization rate of the box car, which is exactly the goal of loading and distributing goods, and the improvement of the space utilization ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com