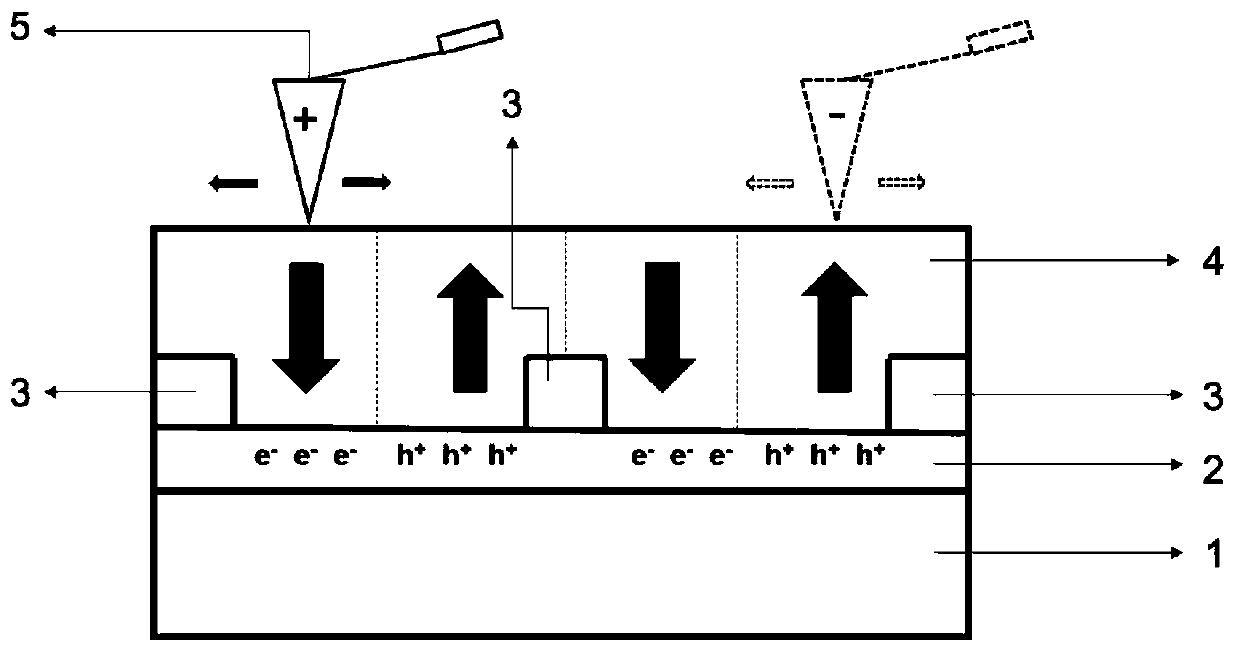

Ferroelectric domain defined series two-dimensional photovoltaic cell and preparation method thereof

A technology of photovoltaic cells and ferroelectric domains, applied in the field of two-dimensional semiconductor photovoltaic devices, can solve problems such as complex processes and difficult control of doping levels, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

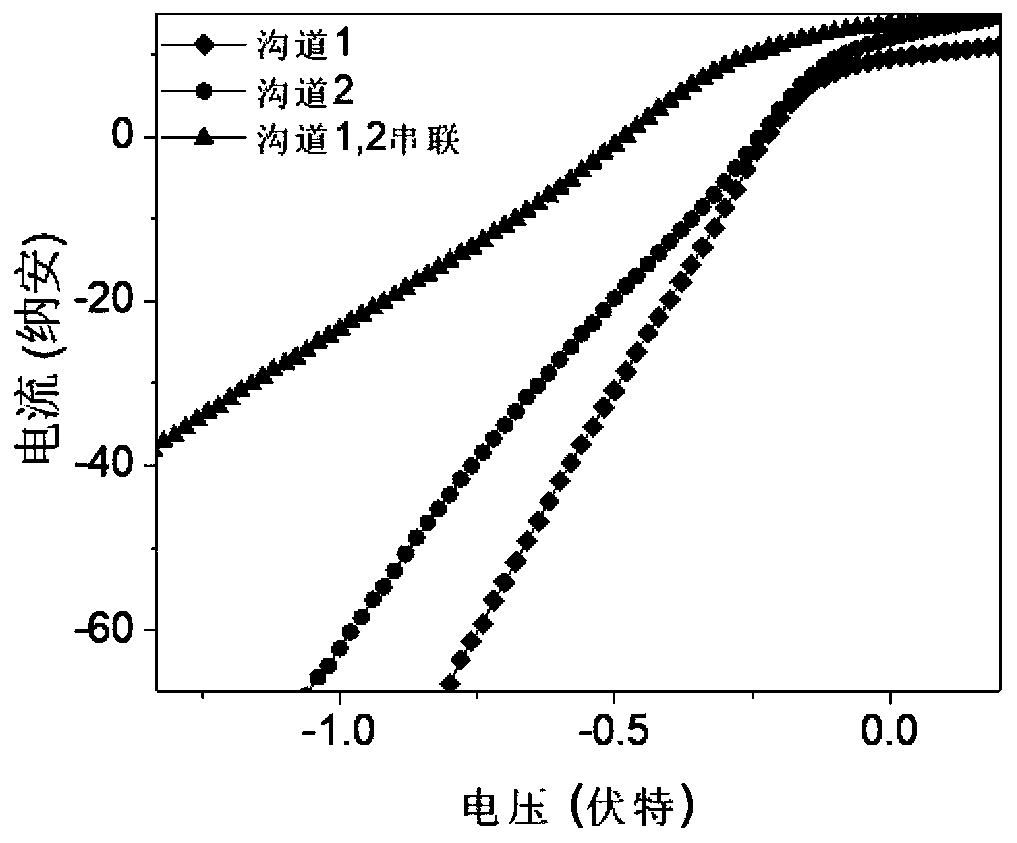

Embodiment example 1

[0037] The specific steps for implementing Case 1 are as follows:

[0038] 1) Preparation of insulating substrate

[0039] The insulating substrate is a silicon substrate covered with silicon dioxide;

[0040] 2) Preparation and transfer of two-dimensional semiconductors of bipolar transition metal compounds

[0041] Bipolar transition metal compound two-dimensional semiconductor 8 nm MoTe by mechanical exfoliation 2 transferred to an insulating substrate.

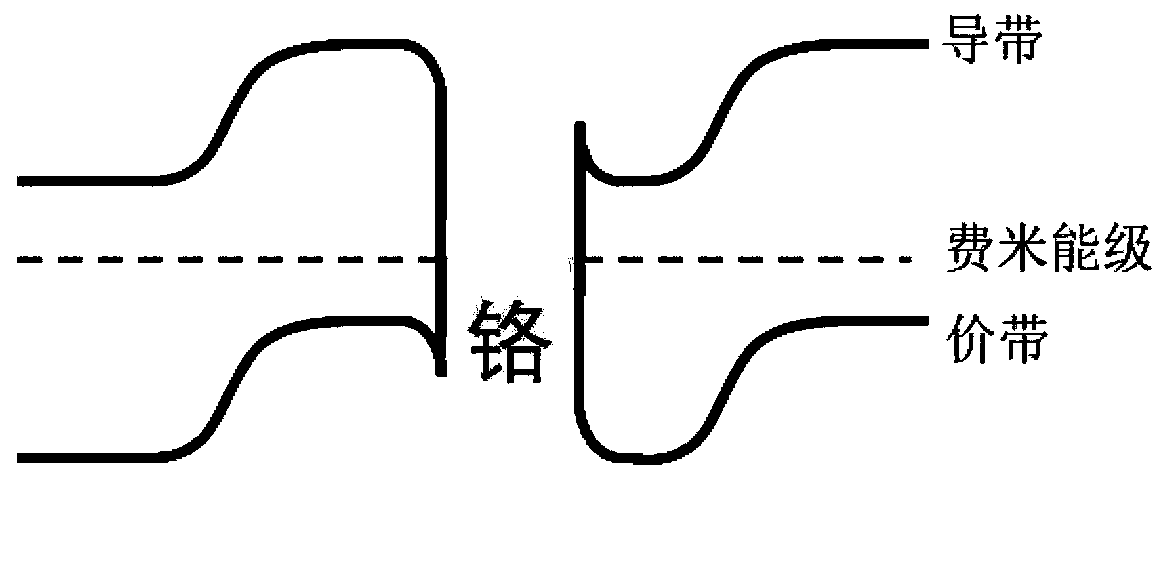

[0042] 3) Metal electrode preparation

[0043] The metal electrode 3 is prepared by using ultraviolet lithography or electron beam exposure technology combined with thermal evaporation and lift-off technology. The electrodes are chromium and gold, the thickness of chromium is 10 nm, and the thickness of gold is 20 nm.

[0044] 4) Preparation of ferroelectric functional layer

[0045] The polyvinylidene fluoride-based ferroelectric functional layer was prepared by spin coating on the prepared device, and annealed at 1...

Embodiment example 2

[0048] The specific steps for implementing Case 2 are as follows:

[0049] 1) Preparation of insulating substrate

[0050] The insulating substrate is a silicon substrate covered with silicon dioxide;

[0051] 2) Preparation and transfer of two-dimensional semiconductors of bipolar transition metal compounds

[0052] Bipolar transition metal compound two-dimensional semiconductor 10 nm MoTe by mechanical exfoliation 2 transferred to an insulating substrate.

[0053] 3) Metal electrode preparation

[0054] The metal electrode 3 is prepared by using ultraviolet lithography or electron beam exposure technology combined with thermal evaporation and lift-off technology. The electrodes are chromium and gold with a thickness of 10 nm and 20 nm, respectively.

[0055] 4) Preparation of ferroelectric functional layer

[0056] The polyvinylidene fluoride-based ferroelectric functional layer was prepared by spin coating on the prepared device, and annealed at 135°C for 2 hours to e...

Embodiment example 3

[0059] The specific steps for implementing Case 3 are as follows:

[0060] 1) Preparation of insulating substrate

[0061] The insulating substrate is a silicon substrate covered with silicon dioxide;

[0062] 2) Preparation and transfer of two-dimensional semiconductors of bipolar transition metal compounds

[0063] Bipolar transition metal compound two-dimensional semiconductor 12 nm MoTe by mechanical exfoliation 2 transferred to an insulating substrate.

[0064] 3) Metal electrode preparation

[0065] The metal electrode 3 is prepared by using ultraviolet lithography or electron beam exposure technology combined with thermal evaporation and lift-off technology. The electrodes are chromium and gold with a thickness of 10 nm and 20 nm, respectively.

[0066] 4) Preparation of ferroelectric functional layer

[0067] The polyvinylidene fluoride-based ferroelectric functional layer was prepared by spin coating on the prepared device, and annealed at 135°C for 2 hours to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com