High-overlapping-efficiency direct liquid cooling laser gain device and laser resonant cavity

A technology of laser gain and efficiency, applied in laser cooling devices, structure/shape of optical resonators, lasers, etc., can solve the problems of low utilization rate of gain medium and complex system, reduce Fresnel reflection and reduce complexity the effect of improving the compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

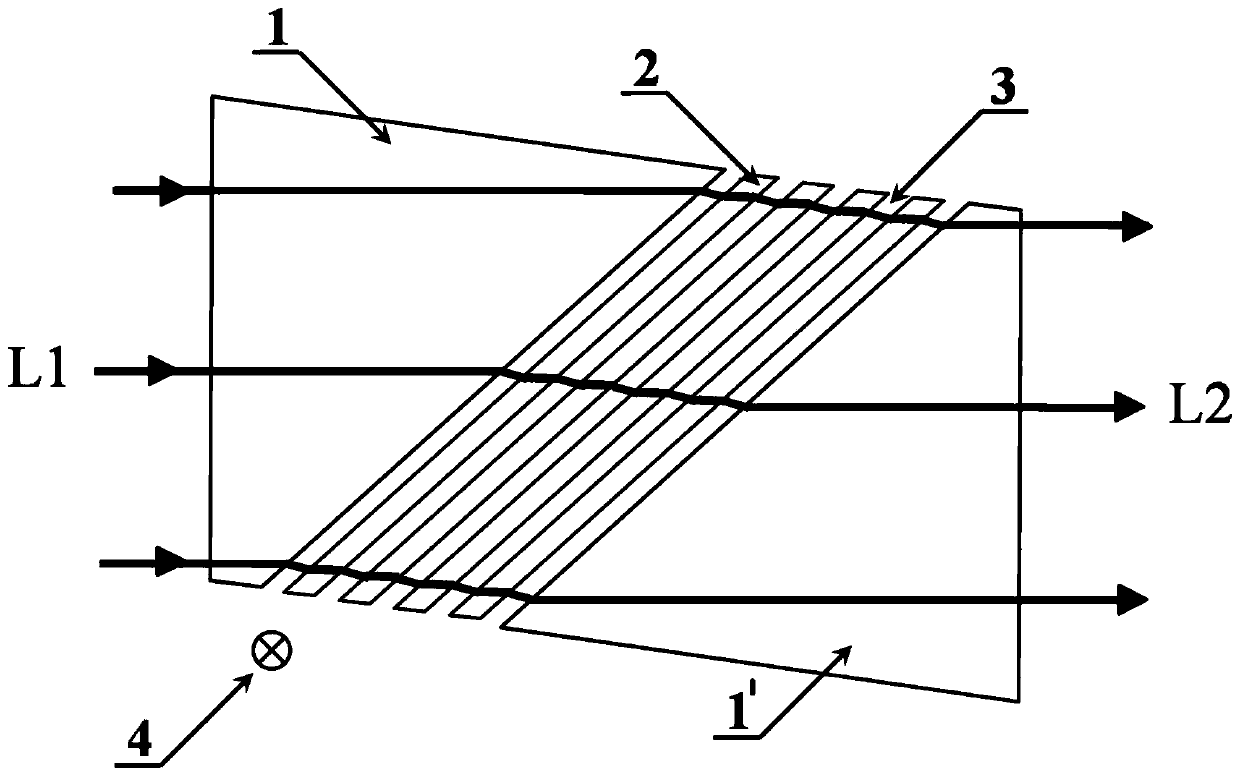

[0035] Such as figure 1 As shown, this embodiment discloses a direct liquid-cooled laser gain device with high overlapping efficiency, and its principle is the same as that of a conventional direct liquid-cooled laser gain device, including an incident light-passing mirror 1, a gain medium 2, and an exit light-passing mirror 1' And the laser cooling liquid 3, the gain medium 2 and the laser cooling liquid 3 are located between the incident light-passing mirror 1 and the exit light-passing mirror 1', the gain medium 2 is formed with a cooling liquid channel, and the laser cooling liquid 3 flows through the cooling liquid The flow channel flows through the surface of the gain medium 2 to cool down the temperature of the gain medium 2, and can obtain higher laser gain per unit volume while reducing the heat load of the monolithic medium.

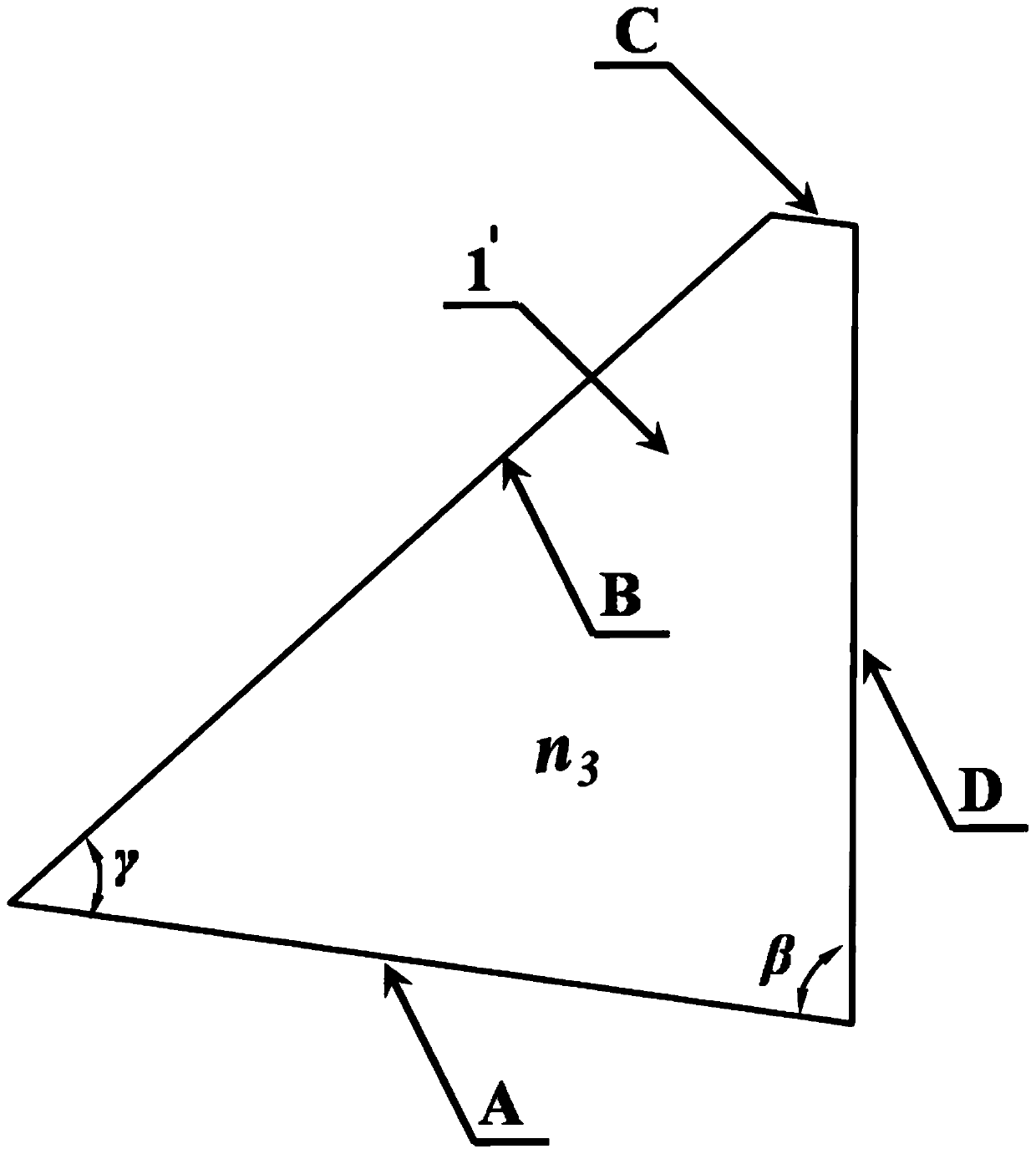

[0036] In the above-mentioned device, at least the incident light-passing mirror 1 is a special-shaped structure, and the angle between the li...

Embodiment 2

[0045] This embodiment discloses the conditions to be satisfied by the design of the angle of the exit surface of the incident light-passing mirror 1 (that is, the angle of the gain medium 2 is determined). The thickness and refractive index of each gain medium 2, the refractive index of the laser cooling liquid 3, and the width of the cooling liquid flow channel are arranged in cooperation with each other, so that the pupil refraction offset of the laser in the gain medium 2 is greater than that of the laser in the laser cooling liquid 3 The pupil refraction offset is the same.

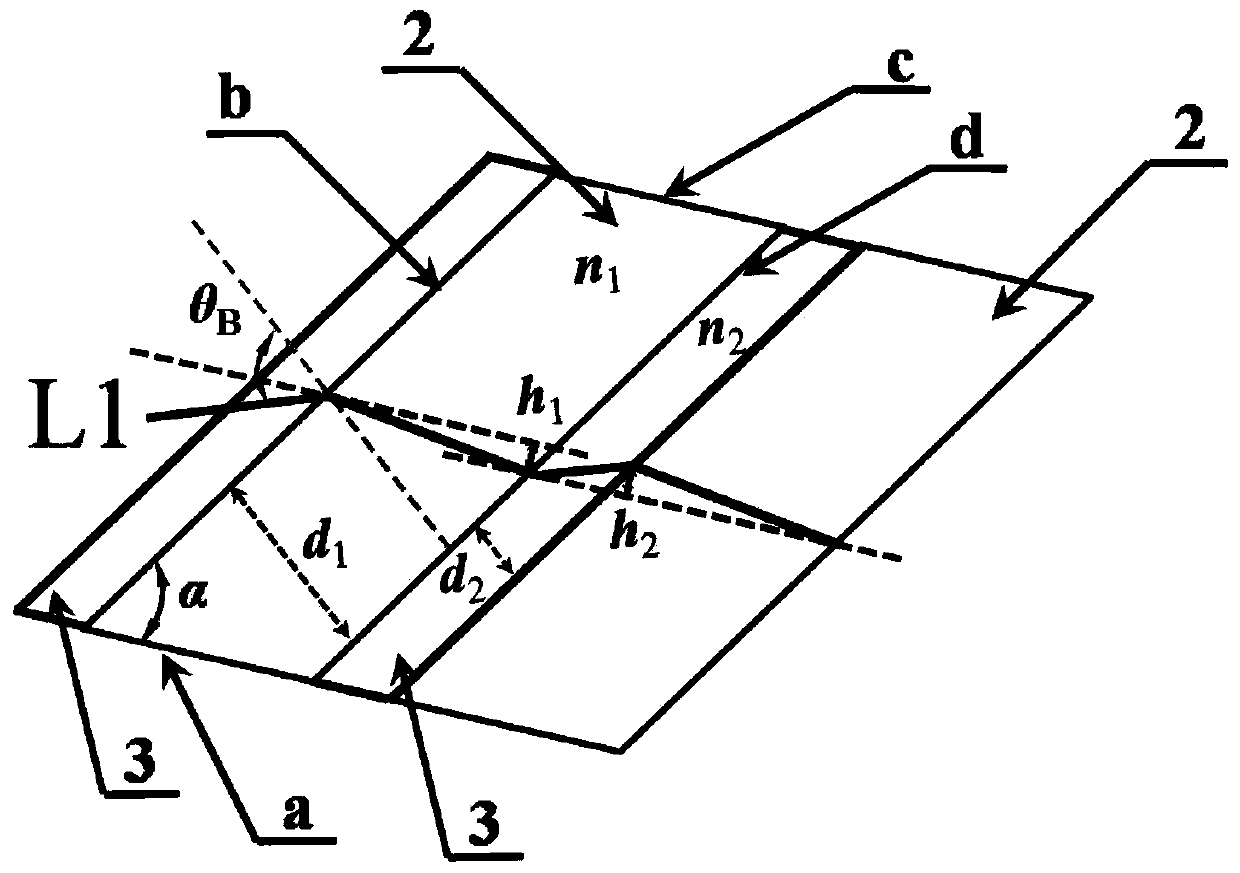

[0046] Such as figure 2 , 3 As shown, set the thickness of the gain medium 2 as d 1 , the channel thickness between the gain medium is d 2 , the refractive index of the gain medium is n 1 , the liquid refractive index n 2 , the tangent angle between the surface a and surface b of the gain medium (the angle between the incident surface and the bottom) is α. In order to meet the pupil refraction...

Embodiment 3

[0055] This embodiment discloses a laser resonant cavity of a direct liquid-cooled laser gain device with high overlapping efficiency based on the above embodiments. Such as Figure 4 As shown, the laser is sequentially provided with a total reflection laser cavity mirror, a first pumping system, a high-overlapping efficiency direct liquid-cooled laser gain device in the above embodiment, a second pumping system, and a laser output mirror along the laser light path direction; the first Both the pumping system and the second pumping system are composed of a pumping source and a dichroic mirror, and the dichromatic mirror is used to transmit the pumping light of the corresponding pumping source, so as to input the pumping light into a high-overlapping efficiency direct liquid-cooled laser gain device , the dichroic mirror also performs total reflection on the laser; the laser output by the total reflection laser mirror is totally reflected by the dichroic mirror of the first pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com