Adsorption recovery system for nitrogen regeneration and adsorption recovery method thereof

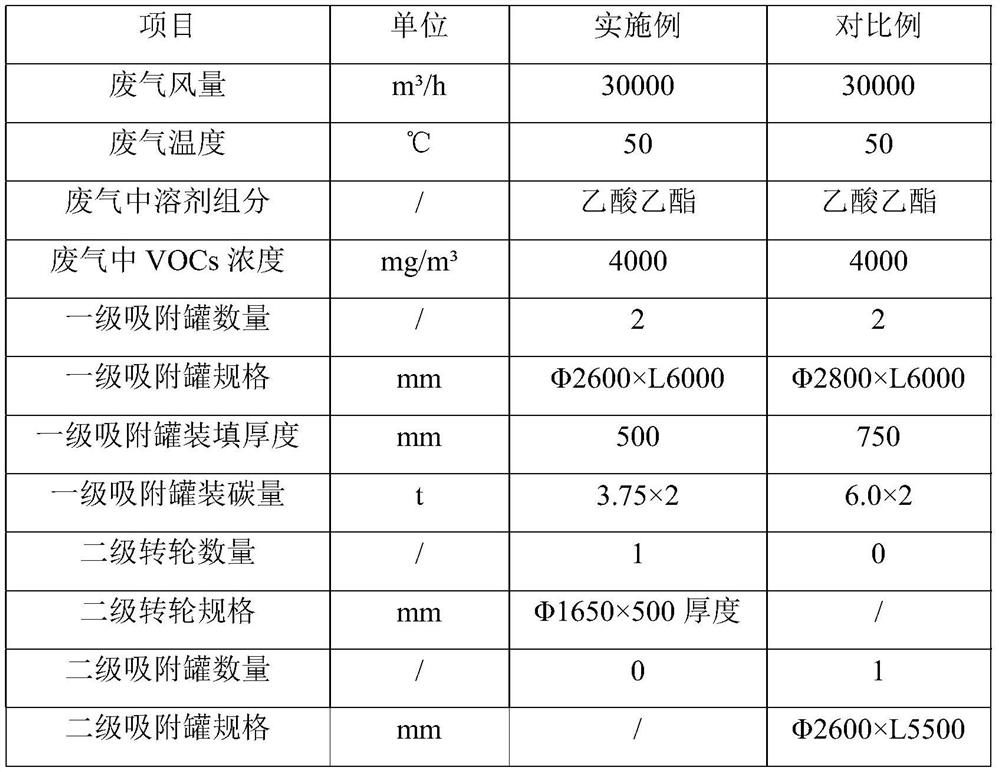

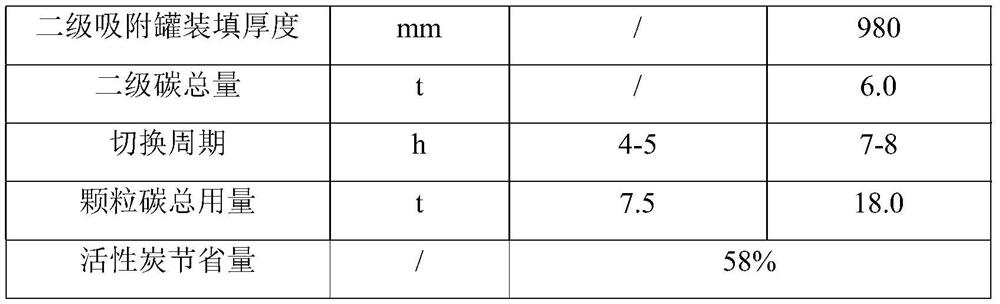

A technology of adsorption recovery and nitrogen, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of abnormally large equipment and huge amount of activated carbon loading, and achieve reduced one-time investment, shortened switching period, and reduced desorption residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

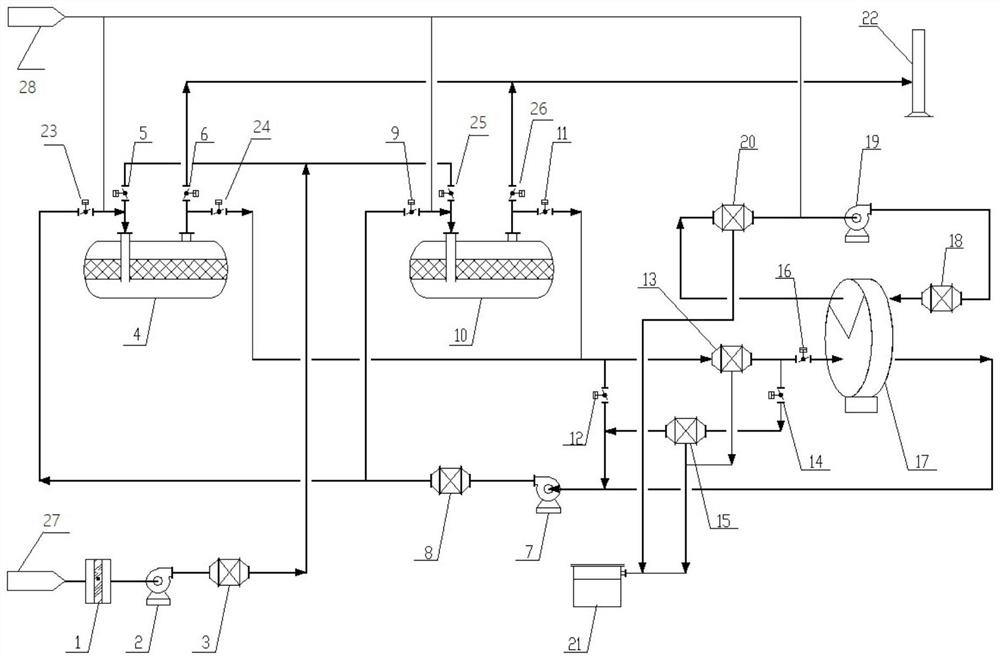

[0049] A nitrogen regeneration adsorption recovery system, such as figure 1 As shown, it includes exhaust gas input equipment, primary adsorption equipment and secondary adsorption equipment connected in sequence, and also includes nitrogen replacement pipelines and primary circulating nitrogen desorption pipes respectively connected with the primary adsorption equipment and secondary adsorption equipment. Road and secondary circulating nitrogen desorption pipeline.

[0050] The primary circulating nitrogen desorption pipeline and the secondary circulating nitrogen desorption pipeline are respectively communicated with the nitrogen replacement pipeline.

[0051] The primary circulating nitrogen desorption pipeline and the secondary circulating nitrogen desorption pipeline are respectively provided with desorption gas condensation recovery equipment.

[0052] The primary adsorption device includes two parallel adsorption tanks 4 and 10 , and the secondary adsorption device is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com